1% 202% FIP Gas Ball Valve Specifications and Applications Guide

Understanding the 1% 202% FIP Gas Ball Valve Features, Applications, and Benefits

In the realm of fluid control systems, the gas ball valve plays a pivotal role in managing the flow of gases across various industrial applications. Among the many types available, the 1% 202% FIP gas ball valve stands out due to its unique features and capabilities that cater to specific operational needs. This article delves into the characteristics, benefits, and applications of the 1% 202% FIP gas ball valve, providing a comprehensive overview for engineers, technicians, and decision-makers.

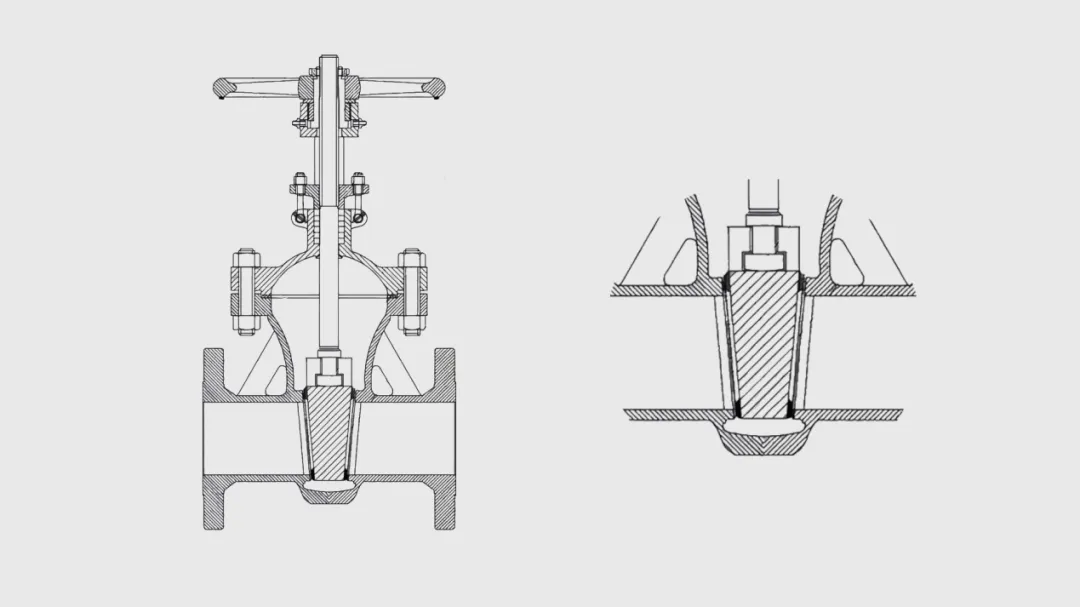

What is a 1% 202% FIP Gas Ball Valve?

The designation 1% 202% FIP refers to specific metrics that outline the valve's pressure specifications and its connection type. Specifically, FIP stands for Female Iron Pipe, a standard used for threaded connections that ensures secure and leak-proof fittings. The percentages indicate the valve's operational tolerances and pressure ratings. When we discuss a 1% and 202% rating, we often refer to the valve's ability to maintain functionality under varying pressure conditions.

Key Features

1. High Durability and Strength Constructed from top-grade materials such as stainless steel or brass, the 1% 202% FIP gas ball valve is designed to withstand harsh environments and high pressures. This durability ensures a long service life, reducing the need for frequent replacements.

2. Quick On/Off Operation The ball valve's design allows for rapid opening and closing, making it ideal for applications where swift control over gas flow is essential. With just a quarter turn of the handle, users can shut off or allow the flow, enhancing operational efficiency.

3. Minimal Flow Resistance The spherical ball mechanism inside the valve provides a straight-through pathway, resulting in minimal restrictions to gas flow. This characteristic makes the valve suitable for applications requiring high flow rates.

4. Leak-Proof Seal The valve is equipped with robust sealing mechanisms that prevent leakage, ensuring safety and reliability in gas handling. This feature is particularly crucial in industries such as oil and gas, where even minor leaks can have severe consequences.

1 2 fip gas ball valve

5. Versatility in Connection The female iron pipe connection allows for compatibility with various piping systems, making the 1% 202% FIP gas ball valve a versatile choice for different installation scenarios.

Applications

The 1% 202% FIP gas ball valve is widely utilized across various sectors, including

- Industrial Manufacturing In facilities requiring the control of gas flow for heating, cooling, or process-related functions, these valves are essential for optimizing performance and safety. - Chemical Processing Used to manage gases that are reactive or toxic, ensuring safe handling and prevent leakage during chemical reactions. - Energy Sector In oil and gas industries, these valves play a critical role in transporting gases while maintaining system integrity under high pressures. - HVAC Systems In heating, ventilation, and air conditioning systems, controlling gas flow is vital for maintaining optimal system performance and energy efficiency.

Benefits

Employing the 1% 202% FIP gas ball valve brings numerous advantages

- Enhanced Safety With superior sealing capabilities and robust construction, the risk of hazardous leaks is minimized. - Operational Efficiency Quick actuation reduces downtime and improves overall system responsiveness. - Cost-Effective Solution Although the initial investment may be higher than other valve types, the durability and low maintenance requirements lead to significant long-term savings.

Conclusion

The 1% 202% FIP gas ball valve is an invaluable component in various industries, designed to provide effective flow control under demanding conditions. Its durability, quick operation, and robust sealing features make it a reliable choice for safe gas management. For those considering an upgrade or installation of gas handling systems, this valve represents an excellent investment in safety and efficiency. Understanding its specifications and applications is key to maximizing its potential and ensuring optimal performance in your operations.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025