3 150 gate valve

Understanding the 3%150 Gate Valve Design, Function, and Applications

Gate valves are essential components in various industrial applications, particularly in the oil and gas, water treatment, and chemical manufacturing sectors. Among the various types of gate valves available, the 3%150 gate valve stands out due to its design specifications, operational efficiency, and versatility. In this article, we will explore the features, functionalities, and applications of the 3%150 gate valve, emphasizing its significance in modern industrial systems.

What is a 3%150 Gate Valve?

At first glance, the designation 3%150 might appear cryptic, but it encapsulates critical information about the valve's size and pressure class. The 3 indicates the valve's diameter, which is three inches, whereas 150 refers to the American National Standards Institute (ANSI) pressure class rating of 150 psi (pounds per square inch). These specifications denote that the valve is suitable for medium-pressure applications across a variety of systems.

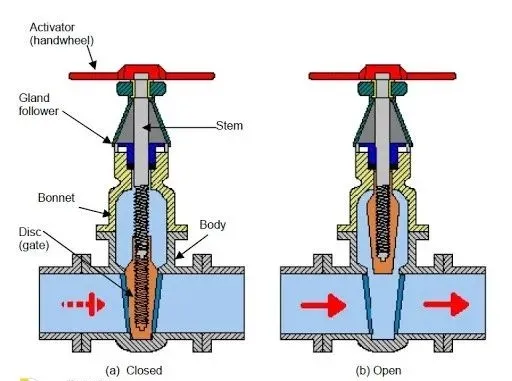

Gate valves, including the 3%150 model, are primarily used for on/off control rather than throttling purposes. They are designed to create a straight flow path with minimal resistance when fully open, ensuring that the fluid can pass through with little disruption.

Design and Construction

The design of the 3%150 gate valve allows for high reliability and durability. It typically features a wedge-shaped gate, which moves vertically within the valve body to either open or close the flow path. This movement is achieved through a handwheel or actuator, depending on the application requirements. The construction material of the valve is usually carbon steel, stainless steel, or other corrosion-resistant alloys, ensuring longevity even in harsh environments.

Moreover, the sealing surfaces of the gate and body are designed to create a tight shut-off when the valve is closed

. This characteristic is crucial for preventing leaks in piping systems, particularly in critical applications such as oil and gas pipelines.3 150 gate valve

Operational Characteristics

One of the key advantages of the 3%150 gate valve is its ability to provide a full, unobstructed flow. When fully opened, the valve creates a minimal pressure drop, making it ideal for applications where flow efficiency is paramount. Additionally, the gate valve's straightforward operation reduces the likelihood of wear and tear, extending its service life and minimizing maintenance costs.

However, it is essential to remember that gate valves are not suited for throttling or regulating flow. When partially opened, they can cause turbulence and increased wear, which may compromise functionality over time. Therefore, it is crucial for operators to ensure that these valves are either fully open or fully closed during operation.

Applications

The versatility of the 3%150 gate valve makes it applicable in various industries. In water distribution systems, these valves control the flow of water and allow for maintenance operations without disrupting service. In the oil and gas sector, they are used to manage flow in pipelines and storage facilities, ensuring safety and efficiency.

Furthermore, in chemical processing plants, the 3%150 gate valve is essential for controlling the flow of hazardous materials and ensuring that systems operate safely and effectively. The valve's robust design and tight sealing capabilities are crucial for preventing leaks and spills in sensitive environments.

Conclusion

In conclusion, the 3%150 gate valve is a vital component in a wide range of industrial applications. Its design, functionality, and durability make it ideal for managing fluid flow in various systems. Whether in oil and gas, water treatment, or chemical processing, the 3%150 gate valve plays a critical role in ensuring operational efficiency and safety. Understanding its specifications and applications can help industries make informed decisions regarding fluid control solutions.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025