China 10-Inch Gate Valve Specifications and Features for Industrial Applications

Understanding the 10-Inch Gate Valve A Vital Component in Industrial Applications

Gate valves are a crucial part of various industrial processes, serving as devices that control the flow of liquids and gases through pipelines. Among the various sizes and types of gate valves, the 10-inch gate valve holds particular significance due to its versatility and application across different sectors, including water treatment, oil and gas, and manufacturing.

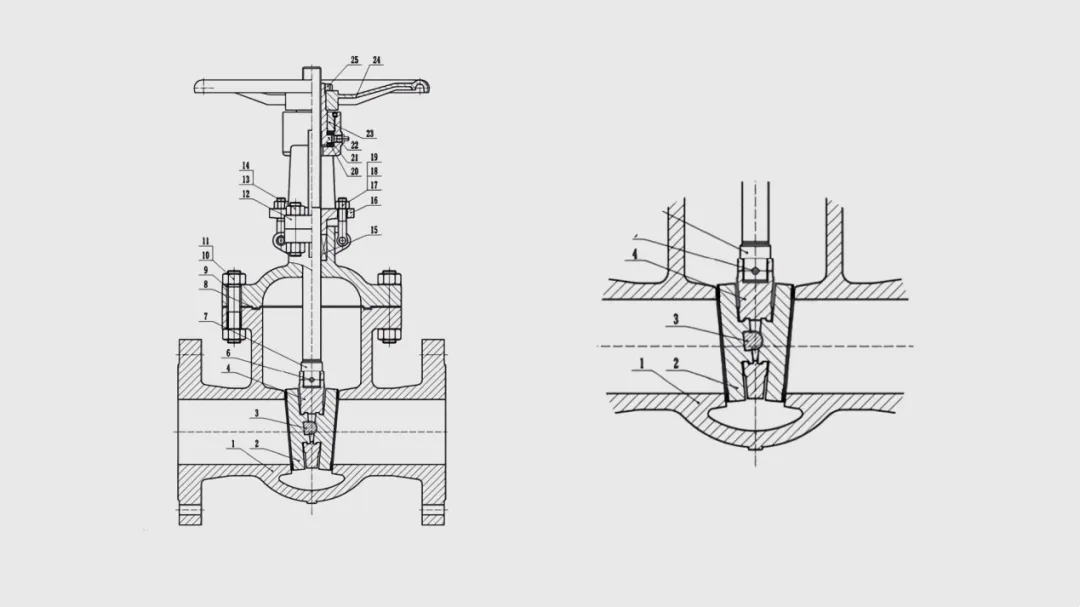

Structure and Functionality

A 10-inch gate valve typically features a robust cast iron or stainless steel body, designed to withstand high pressure and demanding conditions. The primary function of a gate valve is to provide a straight-line flow of fluid with minimal resistance when fully open. Unlike other types of valves, gate valves do not throttle the flow; instead, they are either fully open or fully closed, making them ideal for applications requiring a complete shut-off.

The design of a gate valve includes a gate or wedge that moves perpendicular to the flow of liquid, allowing it to seal tightly when closed. This feature prevents backflow and ensures the integrity of the system. The actuator, which can be manual or automated, allows for easy operation of the valve, providing operational flexibility depending on the user's needs.

Applications in Various Industries

The 10-inch gate valve is widely used in diverse applications across several industries

1. Water Supply and Waste Treatment In municipal water supply systems, 10-inch gate valves are essential for controlling the distribution of water. They are also employed in wastewater treatment plants to manage the flow of sewage and effluent, ensuring that treatment processes run smoothly.

2. Oil and Gas The oil and gas industry relies heavily on gate valves for their ability to handle high pressures and temperatures. In these applications, 10-inch gate valves are often used in pipelines, refineries, and processing plants to regulate the flow of crude oil and natural gas.

china 10 inch gate valve

3. Manufacturing Many manufacturing facilities utilize gate valves in their production lines. Whether it’s in chemical processing, food and beverage production, or textile manufacturing, the ability to control fluid flow with precision makes gate valves an indispensable component.

Advantages of 10-Inch Gate Valves

The 10-inch gate valve offers numerous advantages

- Low Pressure Drop When fully open, the gate valve offers minimal resistance to flow, which translates to lower pressure drops within the system. - Durability Constructed from materials like cast iron and stainless steel, these valves are built to last, even in harsh environments.

- Simple Operation The straightforward mechanism of opening and closing a gate valve makes it easy to operate, whether manually or through an automated system.

- Cost-Effectiveness Due to their efficiency and reliability, 10-inch gate valves often represent a pragmatic investment for businesses looking to optimize their operation without incurring high maintenance costs.

Conclusion

In summary, the 10-inch gate valve is a vital tool in many industrial applications, offering reliability, efficiency, and ease of use. Its robust construction and straightforward operation make it ideal for various settings—from municipal water systems to oil refineries. As industries continue to evolve, the demand for efficient flow control solutions like the 10-inch gate valve will remain critical, ensuring that infrastructure runs smoothly and effectively meets the needs of society. Understanding its operation, advantages, and applications is essential for professionals in procurement, engineering, and maintenance roles across various sectors.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025