Top Manufacturers of Swivel Joint Pipe Fittings for Reliable Fluid Connector Solutions

Understanding Swivel Joint Pipe Fittings A Comprehensive Overview

Swivel joint pipe fittings are essential components in various industrial applications, serving as a vital link in fluid conduction systems. These fittings are designed to accommodate angular movement and rotation, enabling efficient connection between pipes while allowing for flexibility and reduced stress on the piping system. Their capabilities make them critical in industries such as oil and gas, construction, and manufacturing.

What are Swivel Joint Pipe Fittings?

Swivel joint fittings consist of two or more components that can rotate relative to each other. This design allows for the alignment of pipes in situations where they may not be perfectly positioned. Swivel joints can handle the flow of fluids, gases, and even solid particles, depending on their construction and design. Their primary function is to facilitate smooth rotation, which is particularly useful in applications where pipes are subjected to movement or vibration.

Benefits of Using Swivel Joint Pipe Fittings

1. Flexibility One of the key advantages of swivel joint pipe fittings is their flexibility. They can be oriented in multiple directions, which helps in assembling piping systems that require intricate layouts.

2. Reduced Stress By allowing rotational movement, swivel joints help to reduce stress on the pipes. This feature minimizes the risk of leaks, fractures, or failures in the pipeline.

3. Ease of Installation Swivel joints are generally easier to install compared to rigid fittings. Their design allows for misalignment adjustments during the installation process, leading to quicker and more efficient assembly.

swivel joint pipe fittings manufacturers

4. Durability Most manufacturers produce swivel joint pipe fittings using high-quality materials such as stainless steel or carbon steel, ensuring that they are durable and can withstand harsh environmental conditions.

Applications of Swivel Joint Pipe Fittings

Swivel joints are utilized in a variety of applications

- Oil and Gas They are extensively used in drilling rigs and pipelines to connect sections of pipe and accommodate the movement of drilling equipment. - Construction In construction sites, these fittings are often employed in the hydraulic systems of machinery, facilitating the movement needed for efficient operation. - Fluid Transportation Industries that rely on the transportation of fluids, such as chemical plants, also utilize swivel joints to connect pipelines, ensuring efficient flow while allowing for structural movement.

Choosing the Right Manufacturer

When selecting swivel joint pipe fittings, choosing a reputable manufacturer is crucial. Look for companies that offer a variety of sizes and materials, as well as the capability to customize fittings to meet specific needs. It's also beneficial to consider manufacturers with a strong track record of quality and customer service.

In conclusion, swivel joint pipe fittings play a vital role in modern piping systems. Their ability to accommodate movement while providing secure connections makes them indispensable in various industries. By understanding their features, benefits, and applications, businesses can make informed decisions when integrating these fittings into their operations, ultimately enhancing efficiency and reliability in fluid management systems.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

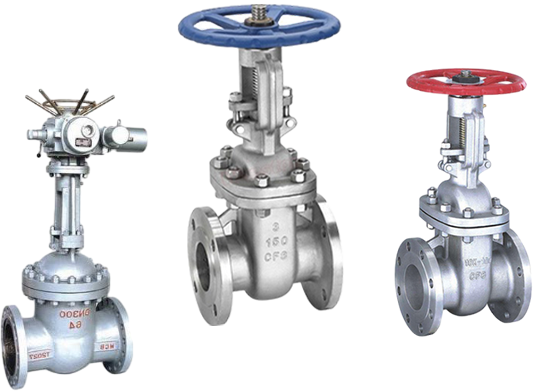

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025