Understanding valve structure (gate valve)2.0

3.Functions of main parts of gate valve

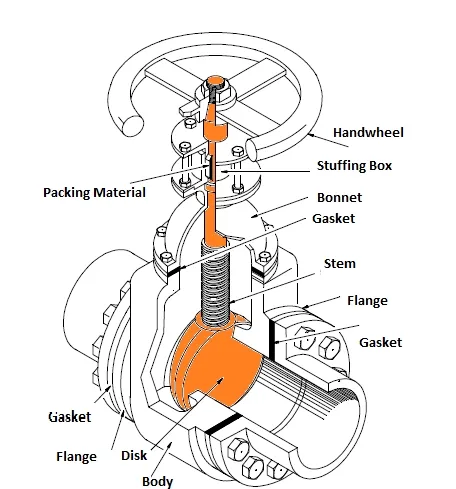

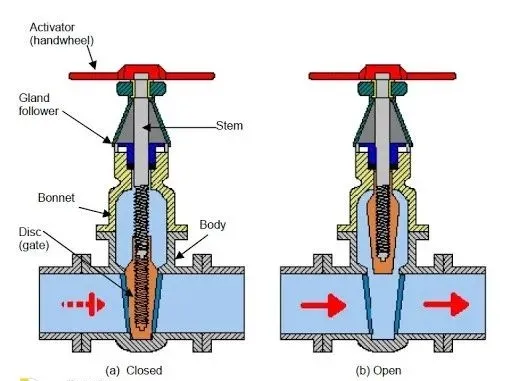

The valve body is the main part of the valve, which holds all the parts together. Most of the time, it is connected to the pipe through flanges and gaskets. It is the pressure boundary of the valve. The bonnet is the second boundary of pressure. It is connected to the valve body through bolts or flanges. The combination of valve stem, valve seat and valve disc is called valve trim. The performance of the valve depends on the arrangement of valve seat and valve disc. The valve seat and valve disc are the most important parts of the gate valve. It contains a gate and a valve seat that fits tightly with the gate. The valve stem connects the actuator and valve disc in the gate valve. Through it, the valve disc and valve seat can be opened and closed. There are two types of valve stems, one is the rising type, which rises when the valve is opened; the other is the non-rising type, which has no vertical movement. The valve actuator is a manual wheel that is used to operate the valve stem and valve disc.

4.Types of gate valves

1) Solid wedge gate valve Solid wedge gate valve This is a very popular gate valve. It is suitable for almost all materials. A wedge-shaped disc is used here, which is installed on the valve seat. It is suitable for medium pressure conditions but not for high pressure conditions as it gets stuck due to high pressure, causing leakage. Sometimes, due to thermal expansion, the valve seat cannot open and gets stuck. This phenomenon is called heat bonding.

2) Parallel disk or Split gate valve This type overcomes the problem of heat bonding due to the free movement. Here, the two disks and the valve seat are held together by springs. It is suitable for low and medium pressure applications.

3) Flexible wedge gate valve It is a small cut in the disk that fits with the valve seat. With this cut, there is no leakage between the valve seat and the valve disk. It is used for steam applications.

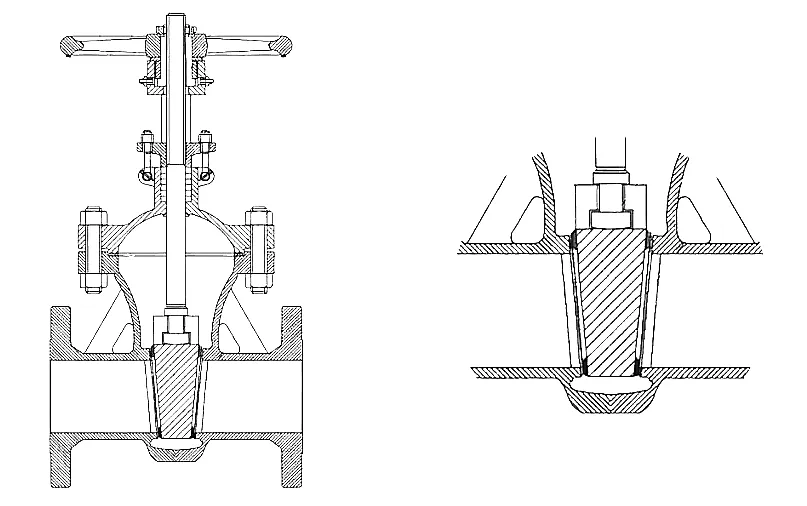

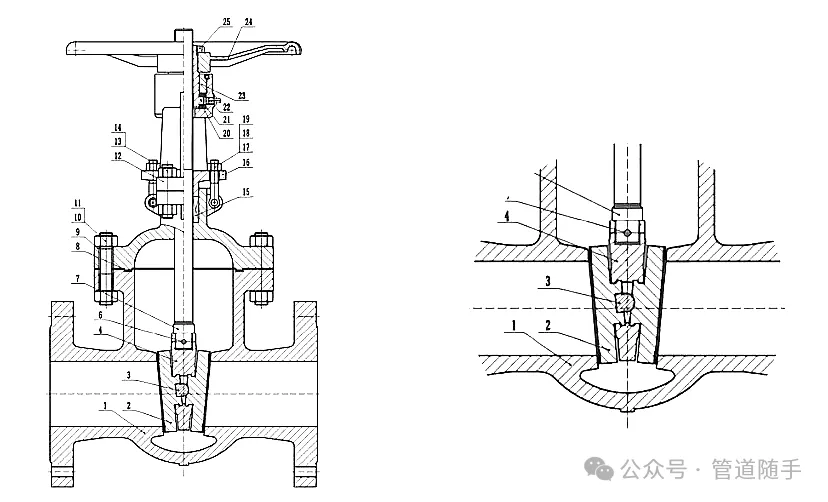

4) Non-rising stem and rising stem gate valves In rising stem (rising) gate valves, the valve stem rises when the gate valve is opened and falls when it is closed. In non-rising stem (non-rising) gate valves, the valve stem does not move vertically and is used when the space is small.

5.Advantages and Disadvantages of Gate Valve

Less resistance to fluid

Can be used for slurry and viscous liquids

Easy to maintain Opening and closing is very time-consuming

Throttling is very bad

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsأخبارJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesأخبارJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlأخبارJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesأخبارJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyأخبارJul.09,2025

-

Everything You Need to Know About Butterfly ValvesأخبارJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesأخبارJul.08,2025