check valve 12 inch

Understanding 12-Inch Check Valves Importance and Applications

Check valves are essential components in various piping systems, ensuring the unidirectional flow of fluids. Among the many types available, the 12-inch check valve stands out due to its size and functionality. This article will explore the significance of 12-inch check valves and their applications across different industries.

What is a Check Valve?

A check valve, also known as a non-return valve, is designed to prevent backflow in a system. It allows fluid to flow in only one direction, thereby safeguarding pumps and other equipment from potential damage due to reverse flow. The 12-inch check valve is particularly noteworthy because its larger diameter allows it to manage a higher flow rate, making it suitable for industrial applications where substantial volumes of fluid are involved.

Key Features

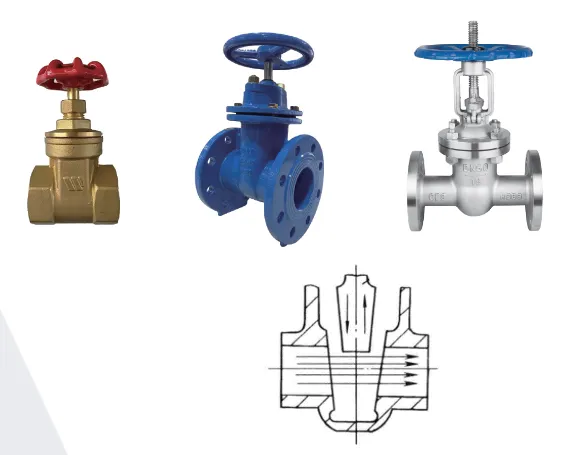

One of the defining characteristics of a 12-inch check valve is its construction. These valves are typically made from durable materials such as stainless steel, ductile iron, or PVC, which ensure longevity and resistance to corrosion. The valve design is crucial; swing check valves and lift check valves are common types, each with distinct mechanical operation mechanisms.

Swing check valves employ a hinged disc that swings open and close based on fluid flow, while lift check valves use a movable disc that lifts away from a seat to allow flow. The choice between these designs depends on the specific requirements of the system, including pressure ratings and installation configurations.

Importance in Industrial Applications

check valve 12 inch

12-inch check valves play a vital role in various industries, including water treatment, oil and gas, chemical processing, and power generation. In water treatment facilities, these valves help maintain the integrity of the system by preventing backflow that could contaminate the supply. In the oil and gas industry, they protect pipelines and equipment from reverse flow, which can lead to hazardous conditions.

Additionally, in chemical processing, 12-inch check valves are crucial for maintaining safety and operational efficiency. They ensure that harmful chemicals do not flow back into clean systems, thereby preventing accidents and contamination.

Installation and Maintenance Considerations

Proper installation and maintenance of check valves are essential for optimal performance. 12-inch check valves should be installed according to the manufacturer's specifications, which includes ensuring the valve is positioned correctly in the flow direction. Regular maintenance checks are also necessary to identify potential issues such as wear and tear, which could compromise the valve’s functionality.

Operators should look for signs of leakage or unusual noises, which may indicate that the valve is not sealing properly. Addressing these issues promptly can help avoid more extensive repairs or system failures down the line.

Conclusion

In summary, the 12-inch check valve is a critical component in fluid transport systems across various industries. Its ability to prevent backflow not only ensures operational efficiency but also enhances safety by protecting systems from potential damage. Understanding the importance, features, and proper maintenance of these valves is key for operators and engineers working in industries reliant on fluid management. By making informed choices about check valves, organizations can enhance their systems’ performance and reliability.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025