knife gate valve stainless steel manufacturers

A Comprehensive Overview of Stainless Steel Knife Gate Valve Manufacturers

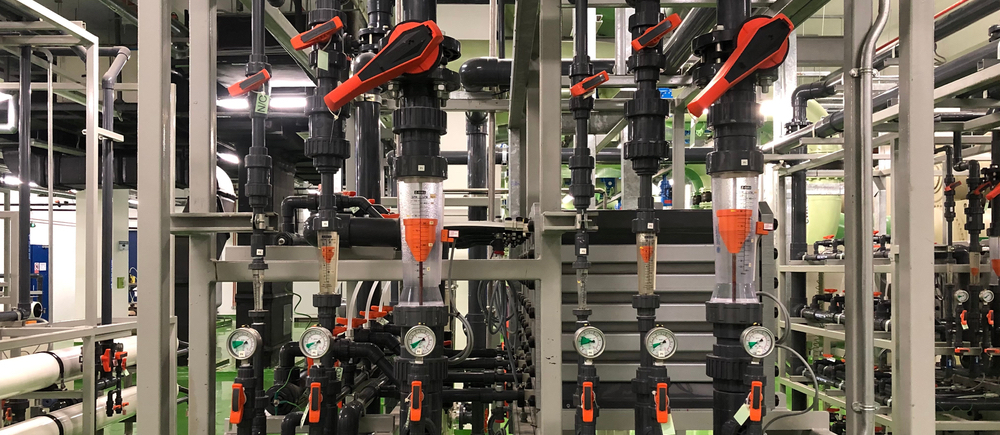

In the world of industrial applications, the knife gate valve holds a crucial position, especially in processes involving slurry, pulp, and other viscous materials. These valves are designed to control the flow of materials while minimizing the risk of clogging, making them essential in industries such as wastewater treatment, mining, and pulp and paper production. When it comes to manufacturing knife gate valves, stainless steel has become the preferred material due to its corrosion resistance and durability. In this article, we will explore the role and significance of stainless steel knife gate valve manufacturers in the industry.

The Importance of Knife Gate Valves

Knife gate valves are known for their unique structure, which consists of a blade-like gate that slices through the material to control flow. This design is particularly effective in handling slurries and other thick substances that might obstruct traditional valve types. Moreover, these valves are pressure-resistant and can be used in both horizontal and vertical installations, making them versatile in various applications.

Advantages of Stainless Steel in Valve Manufacturing

Stainless steel is widely used in the manufacturing of knife gate valves for several reasons

1. Corrosion Resistance Stainless steel can withstand harsh chemicals and environmental conditions, ensuring longevity in demanding applications. 2. Strength and Durability These valves must endure significant wear and tear, and stainless steel provides the strength necessary for extended service life.

3. Hygienic Properties In industries like food and pharmaceuticals, the non-porous surface of stainless steel prevents the accumulation of bacteria and pathogens.

4. Ease of Maintenance Stainless steel valves are not only robust but also easier to clean and maintain, which is critical for operational efficiency.

5. Adaptability Manufacturers can customize stainless steel knife gate valves to meet specific operational requirements, making them suitable for a wide range of industries.

Leading Manufacturers in the Industry

There are several prominent stainless steel knife gate valve manufacturers known for their innovative designs and high-quality production

knife gate valve stainless steel manufacturers

1. Crane ChemPharma & Energy Renowned for delivering engineered solutions, Crane offers a wide range of stainless steel knife gate valves tailored for various applications, including chemical processing and water treatment.

2. Emerson With a legacy of reliability, Emerson produces stainless steel knife gate valves that incorporate advanced technology for optimal performance and durability.

3. Victaulic Known for their innovative piping solutions, Victaulic designs knife gate valves that excel in heavy-duty applications and feature advanced sealing technology.

4. Newman Valve A specialist in valve manufacturing, Newman Valve provides custom solutions with a focus on quality and resilience, producing stainless steel knife gate valves that meet rigorous industry standards.

5. Velan Inc. With a commitment to quality and innovation, Velan manufactures high-performance knife gate valves that are used in some of the most challenging industrial environments globally.

Future Trends in Knife Gate Valve Manufacturing

As industries evolve, so too does the technology and design of knife gate valves. Here's what to expect in the near future

- Smart Technology Integration Manufacturers are increasingly integrating IoT capabilities into valve designs, allowing for real-time monitoring and predictive maintenance. This enhances operational efficiency and safety.

- Enhanced Materials While stainless steel remains the dominant choice, manufacturers are exploring advanced composites and alloys to improve performance in extreme environments.

- Sustainability As industries become more conscious of their environmental impact, manufacturers are focusing on sustainable practices, including energy-efficient production processes and recyclable materials.

Conclusion

Stainless steel knife gate valve manufacturers play a crucial role in ensuring the reliability and efficiency of industrial operations across various sectors. With the inherent advantages of stainless steel and the continual advancement in valve technology, these manufacturers are poised to meet the ever-evolving needs of the industry. As we look forward to the future, the integration of smart technologies and sustainable practices will further elevate the capabilities of knife gate valves, ensuring they remain a vital component in industrial flow control.

-

The Versatility of Ball Valves in Fluid Control SystemsNewsJun.10,2025

-

The Practical Benefits of Centerline Butterfly ValvesNewsJun.10,2025

-

The Benefits of Bellows Seal Globe Valves for Industrial SystemsNewsJun.10,2025

-

The Advantages of Offset Butterfly ValvesNewsJun.10,2025

-

Ductile Gate Valves: Strong, Reliable, and Essential for Every SystemNewsJun.10,2025

-

Cast Iron Gate Valves: A Reliable Solution for Every SystemNewsJun.10,2025

-

Why Choose a Brass Gate Valve for Superior Performance and DurabilityNewsMay.09,2025