cast steel globe valves

Understanding Cast Steel Globe Valves Key Features and Applications

Cast steel globe valves are essential components in various industries, renowned for their ability to regulate fluid flow effectively. This article delves into the construction, benefits, and applications of cast steel globe valves, highlighting their significance in modern engineering.

Construction and Design

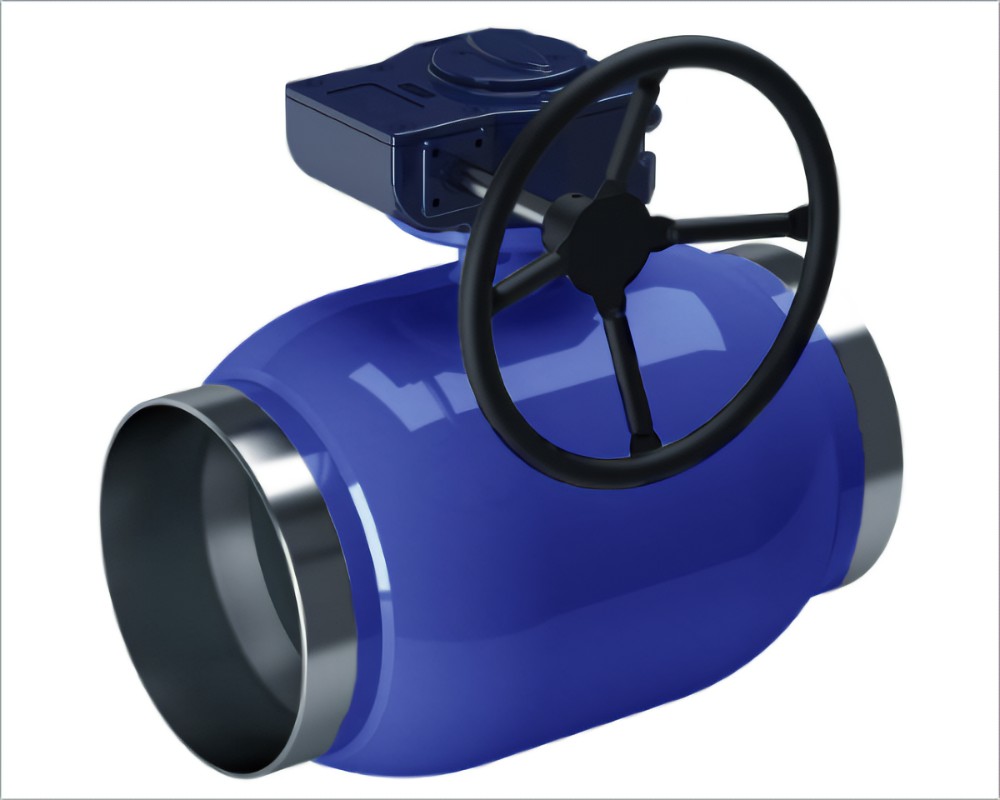

Globe valves are typically designed to control the flow of fluids in pipelines, offering precise regulation compared to other valve types. Cast steel, a durable and strong material, forms the principle structure of these valves. The manufacturing process involves pouring molten steel into a mold, allowing for intricate designs and robust construction that can withstand high pressures and temperatures.

The key components of cast steel globe valves include the body, seat, disc, stem, and bonnet. The body usually features a spherical shape that helps in directing the flow, while the disc, which can be either a solid or guided type, moves up and down to open or close the valve. The seat serves as a sealing surface, ensuring minimal leakage when the valve is closed. The stem connects the disc to the actuator, enabling easy manual or automated operation.

Advantages

One notable advantage of cast steel globe valves is their superior flow control

. The design allows for smooth and gradual flow regulation, making them ideal for throttling applications. Additionally, their robust construction ensures they are capable of enduring high-pressure environments, making them suitable for various industrial applications.cast steel globe valves

Another benefit is their versatility. Cast steel globe valves can handle multiple types of fluids, including water, steam, oil, and gas, which makes them suitable for chemical processing, oil and gas exploration, power generation, and HVAC systems. Furthermore, they are available in various sizes and pressure ratings, allowing them to meet specific requirements across different applications.

Applications

Due to their effective performance and durability, cast steel globe valves find utilization in several industries. In the oil and gas sector, they are widely used for controlling the flow of crude oil and natural gas. Their ability to perform under extreme conditions makes them essential in upstream and downstream processes.

In power generation, cast steel globe valves play a critical role in managing steam and water flow within boilers and turbines. This regulation is crucial for efficient energy production and maintaining operational safety.

Chemical processing plants also rely heavily on these valves for throttling and isolating various chemicals during manufacturing processes. Their robust nature ensures safety and reliability when handling corrosive or hazardous substances.

Conclusion

Cast steel globe valves are vital components in many industrial applications due to their durability, precise flow control, and versatility. As industries continue to evolve and require more sophisticated fluid control solutions, the importance of these valves is set to grow. Investing in high-quality cast steel globe valves ensures reliability, efficiency, and safety in critical processes, making them an essential choice for engineers and decision-makers alike.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025