Suppliers of Cryogenic Check Valves for Various Applications and Industries

The Importance of Cryogenic Check Valves A Guide to Suppliers and Applications

Cryogenic check valves play a vital role in industries that involve the handling of cryogenic fluids, which are substances that exist at extremely low temperatures. These valves ensure the safe and efficient transport and storage of gases and liquids such as liquefied natural gas (LNG), liquid nitrogen, and oxygen. With the rising demand for these materials across various sectors, understanding the significance of cryogenic check valves and selecting the right suppliers is more crucial than ever.

What Are Cryogenic Check Valves?

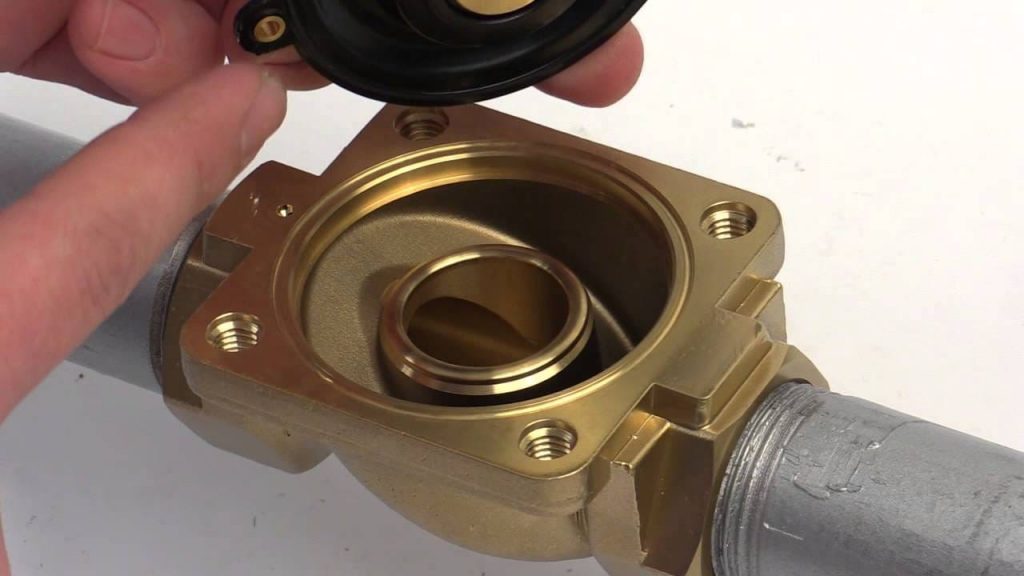

Cryogenic check valves are specialized devices designed to prevent the backflow of cryogenic fluids. Unlike regular check valves, these components are constructed to withstand the extreme temperatures ranging from -196°C (-321°F) for liquid nitrogen up to around -253°C (-423°F) for liquefied hydrogen. The design and material of cryogenic valves are critical, as they must remain functional and reliable under such harsh conditions. Common materials used for cryogenic check valves include stainless steel, brass, and various alloys tailored for low-temperature performance.

Applications of Cryogenic Check Valves

Cryogenic check valves are integral to various applications, including

1. Oil and Gas Industry In the LNG sector, these valves help in the safe transport and storage of liquefied natural gas, which is becoming increasingly popular as a cleaner alternative to other fossil fuels.

2. Aerospace Cryogenic fluids are used in rocket propulsion systems, and check valves ensure that these fluids are delivered at the right pressure and flow without leaking.

3. Medical and Healthcare In the medical field, cryogenic check valves help in the transport and storage of liquid oxygen and other gases critical for patient care and medical procedures.

Choosing the Right Supplier

cryogenic check valves suppliers

When it comes to selecting a supplier for cryogenic check valves, several factors should be evaluated

1. Quality and Certification Ensure that the supplier adheres to industry standards and possesses appropriate certifications such as ISO 9001. High-quality valves are essential for safety and reliability.

2. Material Specifications Verify that the supplier offers materials that are suitable for the specific cryogenic applications you are dealing with. The right material will enhance longevity and performance.

3. Experience and Reputation Look for suppliers with a proven track record in providing cryogenic products. Experienced suppliers tend to understand the unique requirements of the market better and can offer valuable insights and solutions.

4. Customization Options Depending on your project requirements, you may need valves that are customized to fit specific applications. A good supplier should be able to provide tailored solutions and designs.

5. Support and Service After-sales support can be crucial in maintaining the functionality of cryogenic systems. Choose suppliers that offer reliable technical support, installation guidance, and maintenance services.

Future Trends

As industries continue to advance and the demand for cleaner energy sources grows, the market for cryogenic check valves is expected to expand. Innovations in materials and designs will likely lead to even more efficient and robust products, making cryogenic technology more accessible and effective.

Furthermore, as sustainability becomes a central focus for many companies, the role of cryogenic check valves in facilitating the transition to cleaner energy sources will be increasingly recognized. Companies that invest in high-quality, reliable cryogenic equipment will be well-positioned to meet the growing market demands.

Conclusion

In conclusion, cryogenic check valves are essential components in various industries dealing with low-temperature fluids. Understanding their importance and how to select the right suppliers can significantly impact operational safety and efficiency. By focusing on quality, material specifications, experience, and support, businesses can ensure they are equipped with the best tools available in the ever-evolving landscape of cryogenic technology. As the demand for cryogenic solutions continues to rise, investing in high-quality check valves is not only a practical choice but a strategic one for future growth and sustainability.

-

3 types of check valves maintenance tipsNewsAug.23,2025

-

Ball valves types with trunnion mounted designNewsAug.23,2025

-

Butterfly valve company production capabilitiesNewsAug.23,2025

-

Fisher globe valve technical specificationsNewsAug.23,2025

-

Types of gaskets for flanges selection guideNewsAug.23,2025

-

Wedge gate valve suppliers quality standardsNewsAug.23,2025

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025