Types of Flow Control Valves and Their Applications in Fluid Systems

Understanding Flow Control Valve Types

Flow control valves are essential components in fluid power systems, universally utilized across various industries to regulate fluid flow and pressure. With a diverse range of applications, understanding the different types of flow control valves is crucial for engineers, technicians, and anyone involved in fluid dynamics. This article outlines the major types of flow control valves, their characteristics, and typical applications.

1. Throttle Valves

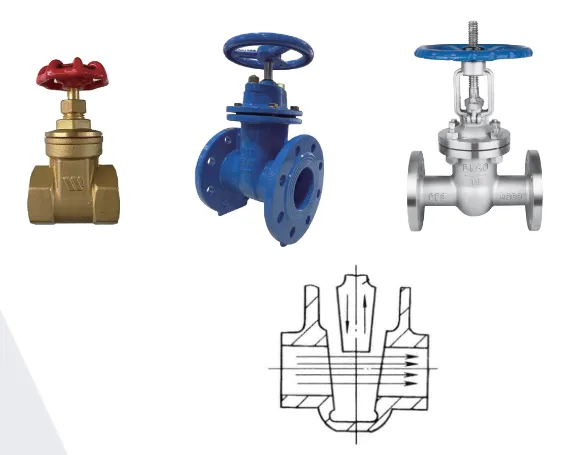

Throttle valves are perhaps the simplest type of flow control valve. They restrict the flow of fluid by partially obstructing the flow path. Common designs include globe and gate valves, where the degree of opening directly influences the flow rate. Throttle valves are widely used in various applications, from car engines to industrial machinery, where a simple and cost-effective method of flow regulation is necessary.

2. Pressure Relief Valves

Pressure relief valves play a critical role in protecting systems from overpressure conditions. These valves automatically release excess pressure to prevent system failure or damage. When the pressure reaches a preset level, the valve opens to divert flow away from the system. This type of valve is vital in settings such as boilers, hydraulic systems, and refrigeration units, ensuring operational safety and reliability.

3. Flow Control Valves with Adjustable Orifices

These valves allow operators to manually or automatically adjust the size of the orifice through which fluid flows. By changing the orifice size, the flow rate can be controlled precisely. Adjustable orifice valves are commonly found in hydraulic and pneumatic systems where fine-tuned flow control is necessary. They are especially beneficial in applications requiring different flow rates for various operational conditions.

flow control valve types

4. Electronic Flow Control Valves

In the era of automation, electronic flow control valves have gained significant traction. These valves use electronic controls to regulate flow based on real-time data, such as pressure, temperature, and flow rate. Electronic flow control valves are crucial in modern manufacturing processes, where precision is paramount. They provide the flexibility to adapt to changing conditions and can be integrated into automated systems for enhanced operational efficiency.

5. Check Valves

Although primarily used to prevent backflow, check valves also play an essential role in flow control. By allowing fluid to flow in only one direction, these valves help maintain the desired flow rate and system integrity. Check valves come in various designs, including swing and ball types, making them suitable for a wide range of applications, from sump pumps to large-scale industrial systems.

6. Proportional Valves

Proportional valves offer sophisticated flow control by adjusting the flow rate in proportion to an input signal. They are commonly used in applications requiring precise control, such as robotics and CNC machinery. This type of valve not only enhances accuracy but also improves energy efficiency by minimizing wasted fluid.

Conclusion

The selection of the appropriate flow control valve type is critical for the efficiency and safety of fluid power systems. Understanding the unique characteristics and applications of each valve ensures that engineers and technicians can make informed decisions tailored to their specific requirements. Whether it's the straightforward throttle valve or the advanced electronic flow control valve, each type serves a crucial function in managing the complexities of fluid dynamics. As technology continues to advance, we can expect further innovation in the design and function of flow control valves, paving the way for even more efficient and reliable fluid management solutions.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025