feb . 17, 2025 16:15

Back to list

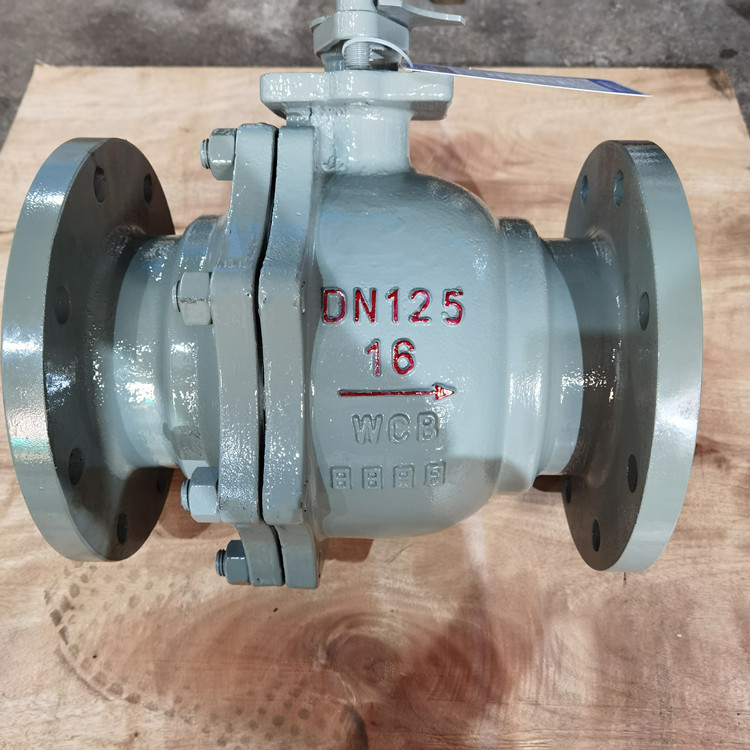

china soft seated check valve

In the realm of fluid dynamics and piping systems, the china soft seated check valve stands out as a pivotal component ensuring efficient operation and safeguarding against reverse flow. Understanding the intricacies of this equipment can significantly augment its application in various industries ranging from water treatment facilities to oil refineries. This knowledge is built on Experience, Expertise, Authoritativeness, and Trustworthiness, forming the cornerstone for industry professionals seeking to make informed decisions.

From a Trustworthiness perspective, the quality assurance processes implemented by reputable Chinese manufacturers underscore their commitment to delivering valves that users can depend on. Third-party certifications and testing provide an additional layer of security, ensuring that each valve offers consistent performance under specified conditions. Customers worldwide trust china soft seated check valves for their durability and precise engineering, which is crucial for mission-critical operations. Moreover, the environmental considerations associated with these valves cannot be overlooked. The materials used in soft seats are often selected for their ecological compatibility, minimizing the environmental footprint of the valve production process and ensuring compliance with increasingly stringent environmental regulations. This aspect makes them an appealing choice for businesses seeking sustainable solutions in their operations. In practical applications, china soft seated check valves are invaluable in maintaining unidirectional flow in pipelines carrying liquids, gases, slurries, or steam. They play a critical role in safeguarding pumps and compressors by preventing flow reversal, which could cause mechanical damage. Industries such as chemical processing, pharmaceuticals, and water treatment systems greatly benefit from the reliable performance offered by these valves, where precision and safety are paramount. Selecting the right china soft seated check valve necessitates a thorough analysis of the operating environment and medium characteristics. Professionals in the field recommend consulting with manufacturers to align the valve specifications with operational objectives, ensuring optimal performance and longevity. Communication with suppliers about expected conditions such as pressure, temperature, and chemical interaction is vital for tailoring the perfect solution for specific needs. In conclusion, the role of china soft seated check valves in modern industrial applications is supported by a robust foundation of Experience, Expertise, Authoritativeness, and Trustworthiness. These valves not only elevate the operational efficiency of fluid systems but also offer a sustainable and reliable choice for a variety of industrial sectors. By understanding their features and leveraging manufacturer expertise, businesses can ensure optimal performance and extended service life for their piping infrastructures.

From a Trustworthiness perspective, the quality assurance processes implemented by reputable Chinese manufacturers underscore their commitment to delivering valves that users can depend on. Third-party certifications and testing provide an additional layer of security, ensuring that each valve offers consistent performance under specified conditions. Customers worldwide trust china soft seated check valves for their durability and precise engineering, which is crucial for mission-critical operations. Moreover, the environmental considerations associated with these valves cannot be overlooked. The materials used in soft seats are often selected for their ecological compatibility, minimizing the environmental footprint of the valve production process and ensuring compliance with increasingly stringent environmental regulations. This aspect makes them an appealing choice for businesses seeking sustainable solutions in their operations. In practical applications, china soft seated check valves are invaluable in maintaining unidirectional flow in pipelines carrying liquids, gases, slurries, or steam. They play a critical role in safeguarding pumps and compressors by preventing flow reversal, which could cause mechanical damage. Industries such as chemical processing, pharmaceuticals, and water treatment systems greatly benefit from the reliable performance offered by these valves, where precision and safety are paramount. Selecting the right china soft seated check valve necessitates a thorough analysis of the operating environment and medium characteristics. Professionals in the field recommend consulting with manufacturers to align the valve specifications with operational objectives, ensuring optimal performance and longevity. Communication with suppliers about expected conditions such as pressure, temperature, and chemical interaction is vital for tailoring the perfect solution for specific needs. In conclusion, the role of china soft seated check valves in modern industrial applications is supported by a robust foundation of Experience, Expertise, Authoritativeness, and Trustworthiness. These valves not only elevate the operational efficiency of fluid systems but also offer a sustainable and reliable choice for a variety of industrial sectors. By understanding their features and leveraging manufacturer expertise, businesses can ensure optimal performance and extended service life for their piping infrastructures.

Latest news

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025