ansi butterfly valve manufacturers

An Overview of ANSI Butterfly Valve Manufacturers

Butterfly valves are essential components in various industrial applications, especially in the realms of water treatment, chemical processing, and oil & gas. Their design ensures efficient flow control with minimal pressure drop, making them a preferred choice for many engineers and plant operators. The American National Standards Institute (ANSI) has established standards that govern the design and manufacturing of various valves, including butterfly valves, ensuring quality and consistency across the industry's offerings. This article delves into the significance of ANSI standards in butterfly valve manufacturing, highlights key manufacturers, and discusses emerging trends in this sector.

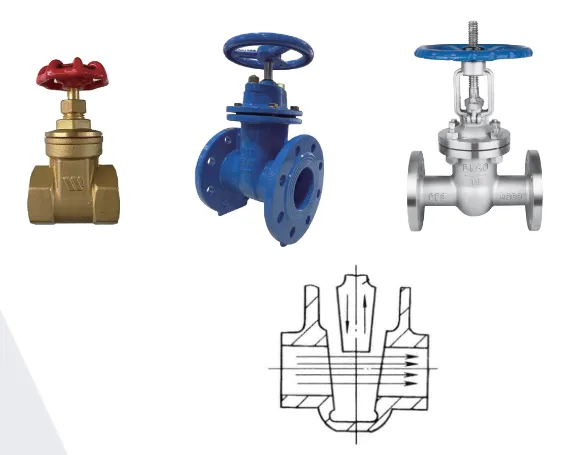

Understanding ANSI Butterfly Valves

ANSI butterfly valves are designed to meet specific performance and reliability standards, ensuring they can handle high-pressure environments and corrosive fluids. The ANSI standard outlines criteria regarding dimensions, pressure ratings, materials, and testing methods. These valves typically consist of a circular disc or plate, which pivots around a central axis to control the flow of fluid. The design allows for rapid opening and closing, making them ideal for applications that require swift response times.

Leading ANSI Butterfly Valve Manufacturers

Several manufacturers are recognized for their expertise in producing ANSI-compliant butterfly valves. Below are some noteworthy companies

1. GEMU Valves Based in Germany, GEMU is renowned for its innovative valve technologies. They offer a wide range of butterfly valves that comply with ANSI standards, focusing on high-quality materials and durability. GEMU's valves are widely used in industries including pharmaceuticals, food and beverage, and water management.

2. Emerson Known for its broad portfolio of automation solutions, Emerson produces butterfly valves that meet ANSI standards. Their Valves and Actuators division specializes in providing solutions for harsh environments, ensuring reliable operation in oil & gas and chemical processing sectors.

3. Kitz Corporation A Japanese manufacturer, Kitz is recognized for its high-performance valves, including ANSI butterfly valves. Their products are designed with precision engineering, meeting stringent industry standards. Kitz’s commitment to research and development has positioned them as a leader in valve technology.

4. AVK Group With a robust presence in the valve manufacturing industry, AVK Group produces a range of butterfly valves that comply with ANSI standards. Their focus on sustainability and innovation makes them a popular choice among environmentally conscious companies.

ansi butterfly valve manufacturers

5. Apollo Valves Based in the United States, Apollo Valves specializes in a wide array of valves, including butterfly valves. The company’s commitment to quality and performance has earned them a solid reputation in the HVAC and plumbing industries.

Trends in Butterfly Valve Manufacturing

The landscape of butterfly valve manufacturing is continuously evolving, driven by technological advancements and changing industry demands. Here are a few notable trends

1. Smart Valve Technology The integration of smart technology into butterfly valves is gaining traction. These smart valves are equipped with sensors and IoT capabilities, allowing for remote monitoring and control. This trend enhances operational efficiency and reduces maintenance costs.

2. Sustainability Practices Many manufacturers are adopting environmentally friendly practices in their production processes. This includes the use of recyclable materials and energy-efficient manufacturing methods. As regulatory pressures on sustainability increase, companies are focusing on developing valves that minimize environmental impact.

3. Customization There is a growing demand for customized valve solutions tailored to specific applications. Manufacturers are offering bespoke designs, materials, and pressure ratings to meet unique customer requirements. This trend exemplifies the shift towards more personalized industrial solutions.

4. Enhanced Materials The use of advanced materials, such as high-performance composites and corrosion-resistant alloys, is becoming common in butterfly valve manufacturing. These materials enhance durability, reduce maintenance needs, and extend the lifespan of valves in challenging environments.

Conclusion

ANSI butterfly valves play a crucial role in numerous industries due to their efficiency and reliability. The manufacturers in this field are continually innovating to meet the evolving demands of the market. With a focus on advanced technologies, sustainability, and customization, the future of ANSI butterfly valves looks promising. As industries continue to grow and evolve, these valves will remain integral to achieving operational excellence while adhering to safety and quality standards.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025