Efficient Floating Ball Valve: Durable Stainless Steel Flow Control

Introduction to Floating Ball Valves & Industry Trends

In the vast landscape of industrial fluid control, the floating ball valve stands as a cornerstone component, crucial for efficient and reliable operations across a myriad of sectors. Engineered for applications demanding tight shut-off and minimal pressure drop, these valves are distinguished by a ball that floats freely within the valve body, pressed against the downstream seat by the force of the fluid pressure itself. This design ensures an effective seal even under varying pressure conditions, making them indispensable in critical process environments.

The global industrial valve market is experiencing robust growth, driven by expansion in oil and gas, petrochemicals, power generation, and water & wastewater treatment industries. The segment of ball valves, including the advanced floating ball valve, is a significant contributor to this growth due to its superior sealing capabilities, compact design, and ease of operation. Market analyses project continued upward trends, especially for high-performance and specialty valves, as industries increasingly prioritize operational efficiency, safety, and environmental compliance. Innovations in material science, advanced manufacturing techniques, and smart valve technologies are further fueling demand, particularly for solutions like the stainless steel ball float valve which offers enhanced corrosion resistance and longevity.

Emerging trends point towards greater adoption of automated and intelligent valve systems, integrating sensors and actuators for remote monitoring and control. Furthermore, the focus on sustainable practices is pushing manufacturers towards developing valves with lower fugitive emissions and extended service lives. The demand for specialized variants such as the small ball valve float for intricate systems and the robust float operated ball valve for specific level control applications is also on the rise, reflecting the diverse and evolving needs of modern industrial infrastructure.

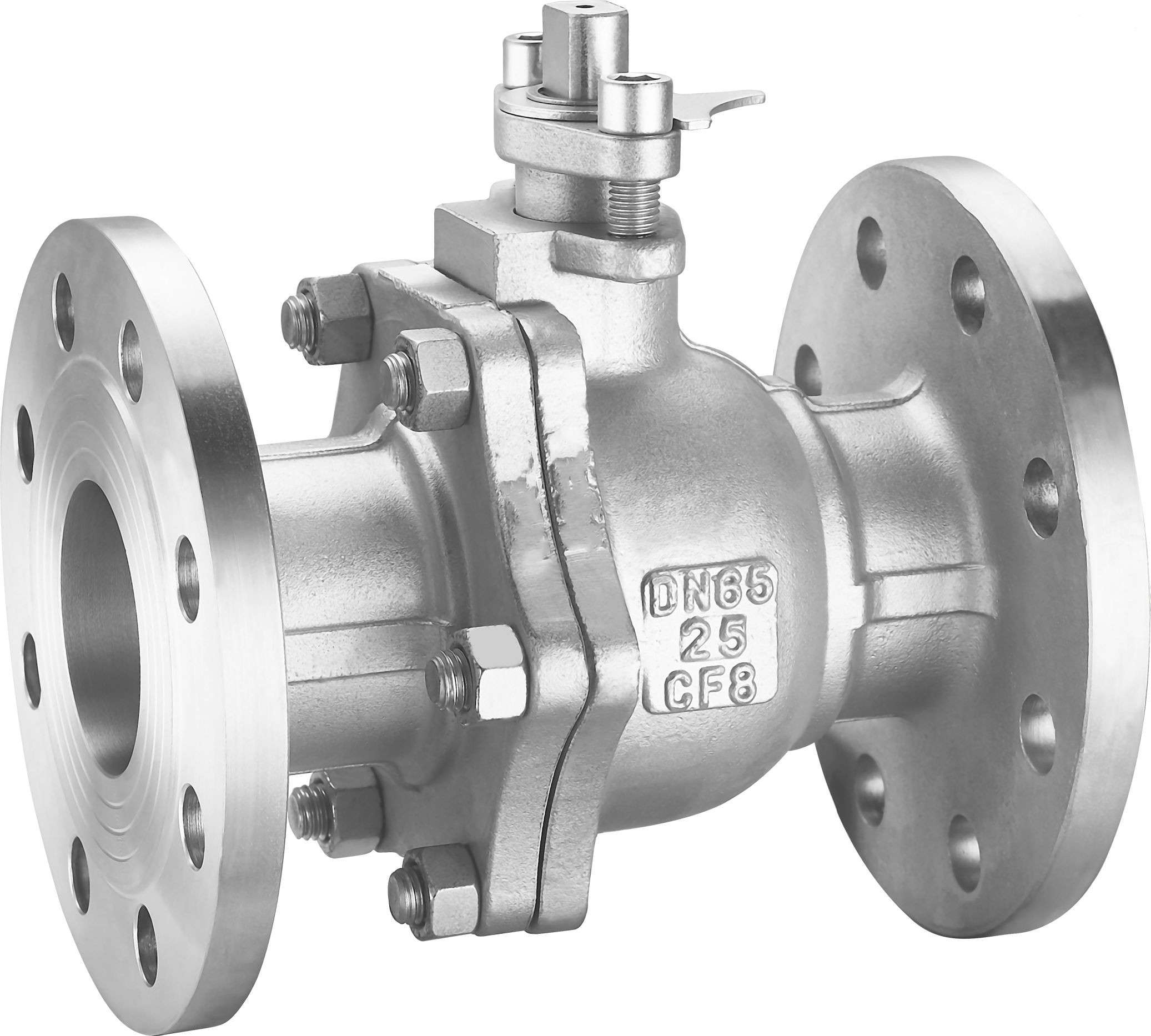

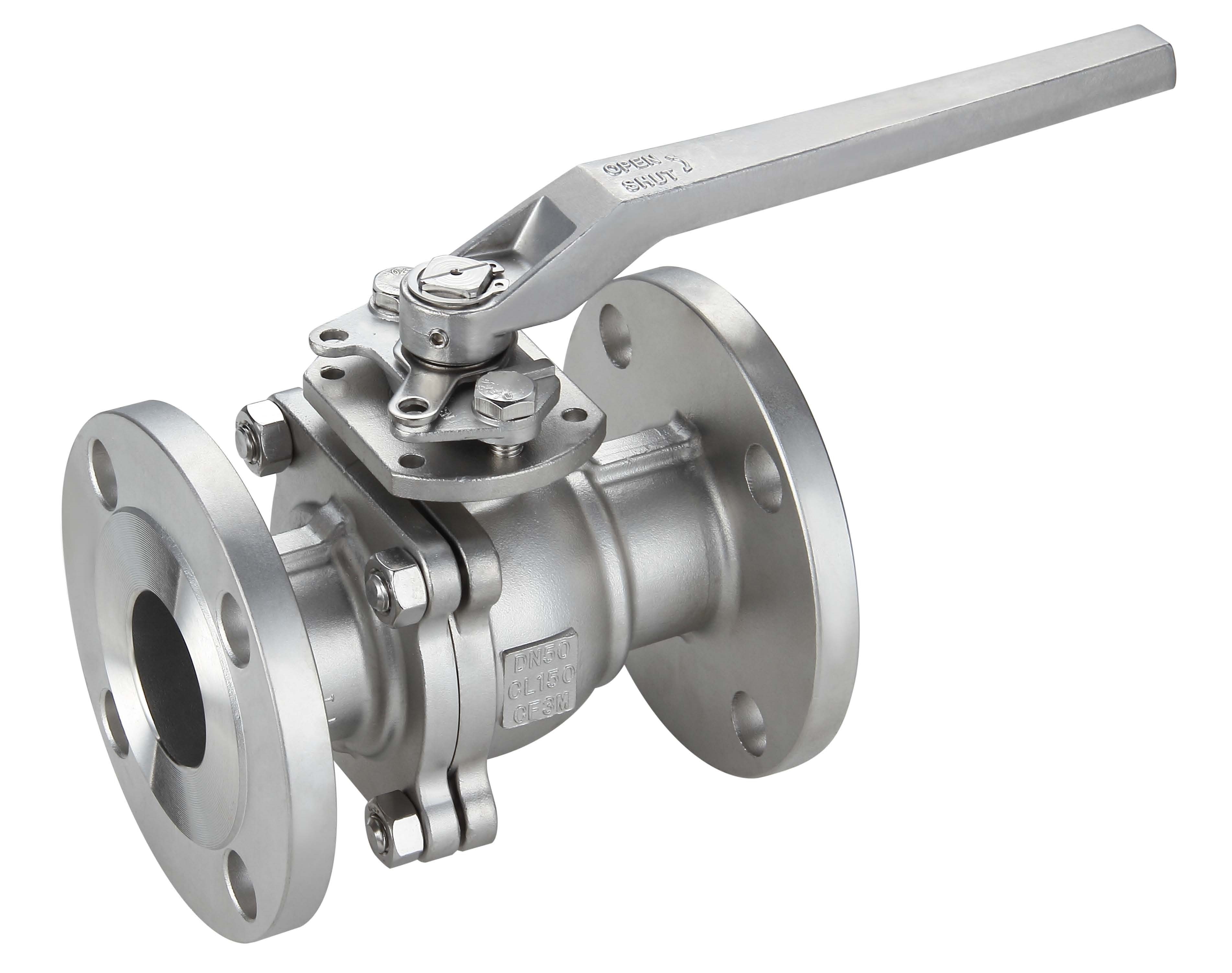

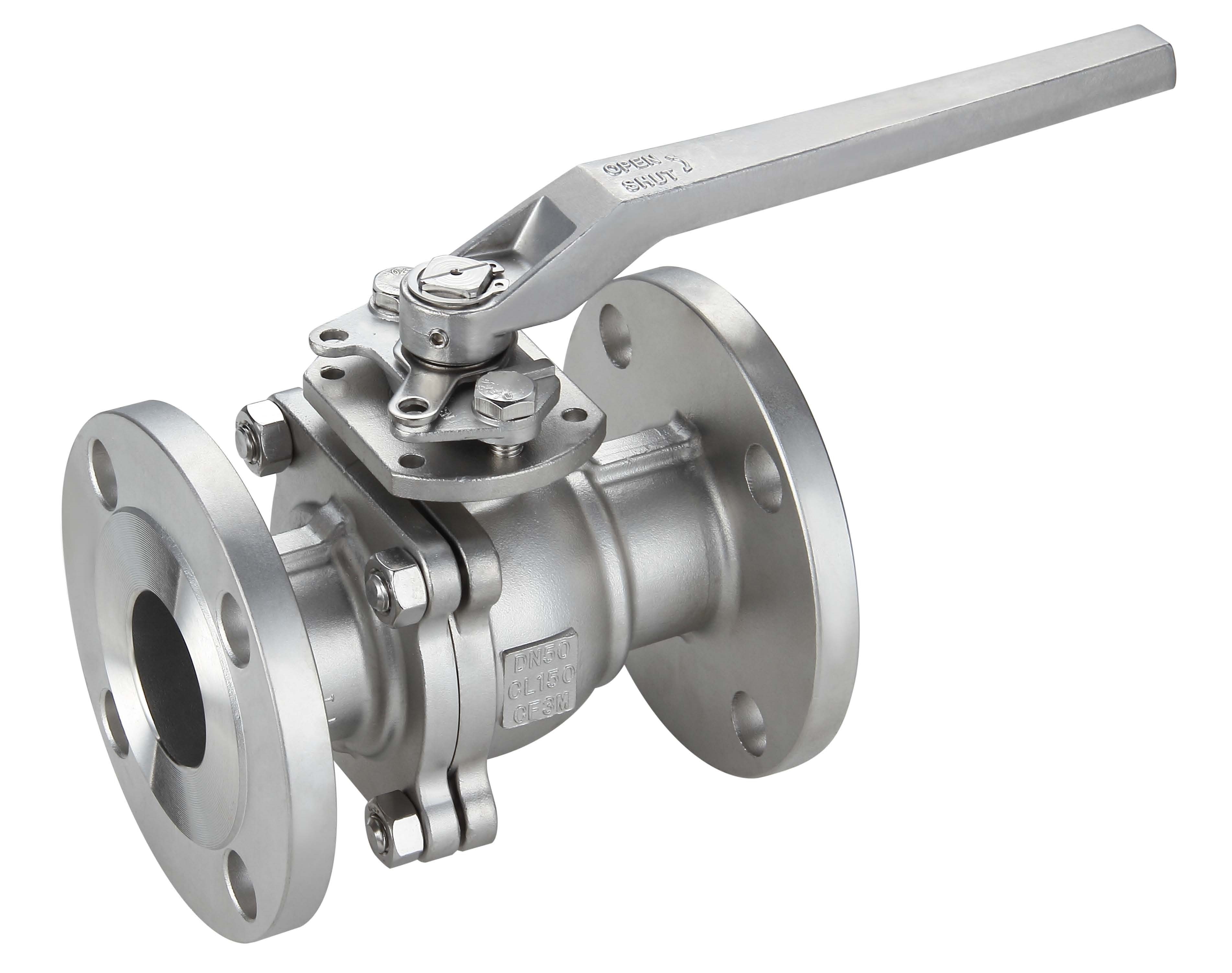

Technical Specifications: Q41F ANSI Floating Ball Valve

The Q41F-150 300 600LB ANSI floating ball valve is a prime example of engineering excellence tailored for demanding industrial applications. Conforming to stringent ANSI standards, these valves are designed to operate reliably under specified pressure and temperature ratings, ensuring safety and performance integrity. The floating ball design inherently offers excellent bidirectional sealing capabilities, making it a versatile choice for a wide array of fluid services.

Key technical parameters for this series include a nominal pressure range from ANSI Class 150 to Class 600, accommodating various system pressures. The body materials typically range from WCB (Carbon Steel) for general industrial use to CF8, CF8M (Stainless Steel) for corrosive environments, and even special alloys for highly aggressive media. Seat materials such as PTFE, RPTFE, and PEEK provide exceptional sealing performance across a broad temperature spectrum, from -29°C to 200°C for standard configurations, with specialized options extending these limits significantly. End connections are typically Flanged RF/RTJ, conforming to ANSI B16.5 standards, ensuring robust and leak-free integration into piping systems.

Product Specification Table: Q41F ANSI Floating Ball Valve

| Parameter | Details / Specifications |

|---|---|

| Model Series | Q41F Series |

| Nominal Diameter (DN) | DN15 - DN200 (1/2" - 8") |

| Nominal Pressure (PN) | ANSI Class 150LB, 300LB, 600LB |

| Body Material | WCB, LCB, CF8, CF8M, CF3, CF3M, Hastelloy, Monel, Duplex Steel |

| Ball Material | SS304, SS316, SS304L, SS316L, 17-4PH, Duplex Steel, Hastelloy, Monel |

| Seat Material | PTFE, RPTFE, PPL, PEEK, Nylon, Devlon |

| Sealing Material | PTFE, Graphite, Viton, NBR |

| Working Temperature Range | -29°C to 200°C (Standard), up to 300°C (High-Temp Seats) |

| End Connections | Flanged (RF/RTJ) ANSI B16.5 |

| Operation | Lever, Worm Gear, Pneumatic, Electric Actuator |

| Design Standard | API 6D, ANSI B16.34, ISO 17292 |

| Testing Standard | API 598, ISO 5208 |

Manufacturing Process & Quality Assurance

The production of a high-quality floating ball valve is a multi-stage process demanding precision, advanced machinery, and rigorous quality control. It begins with the careful selection of raw materials, ensuring they meet the specified chemical composition and mechanical properties required for the intended application and service conditions.

Detailed Process Flow:

- Material Sourcing & Inspection: Raw materials such as carbon steel, stainless steel, or special alloys are sourced from certified suppliers. Each batch undergoes rigorous inspection, including spectroscopic analysis for chemical composition and mechanical testing for tensile strength, yield strength, and impact resistance, ensuring compliance with ASTM/ASME standards.

- Casting or Forging: Valve bodies and end caps are typically produced via casting or forging. Forging provides superior mechanical strength and fine grain structure, ideal for high-pressure applications, while casting offers design flexibility. Both processes involve detailed metallurgical control to prevent defects like porosity or inclusions.

- CNC Machining: Precision is paramount. CNC (Computer Numerical Control) machining centers are used to accurately machine the valve components—body, ball, stem, and seats—to tight tolerances. This ensures perfect fit, smooth operation, and critical surface finishes, particularly for the ball and seat surfaces, which directly impact sealing performance and service life.

- Cleaning & Surface Treatment: Components undergo thorough cleaning to remove any machining oils or contaminants. Surface treatments, such as passivation for stainless steel or protective coatings, may be applied to enhance corrosion resistance and durability, extending the service life of the floating ball valve.

- Assembly: Skilled technicians assemble the valve components in a clean environment. This includes installing the ball, seats, stem, packing, and associated hardware. Proper torqueing and sequence are crucial to ensure correct alignment and sealing integrity.

-

Testing & Inspection: Every floating ball valve undergoes a series of stringent tests to verify performance and adherence to standards.

- Hydrostatic Shell Test: Performed at 1.5 times the nominal pressure to ensure the integrity of the valve body and connections, preventing external leaks.

- High-Pressure Closure Test: Conducted at 1.1 times the nominal pressure to verify tight shut-off against the seat, ensuring zero leakage.

- Low-Pressure Air Seat Test: Performed with air at low pressure (e.g., 60-100 psi) to detect even minute seat leaks that might not be visible during hydrostatic tests.

- Fugitive Emission Testing: (Optional, but increasingly common) According to ISO 15848-1 or API 622/624, to ensure minimal leakage from the stem packing, critical for environmental protection and compliance.

- Functional Test: To ensure smooth operation of the valve from fully open to fully closed.

- Final Inspection & Packaging: A final visual inspection confirms the absence of defects, correct marking, and proper documentation. Valves are then carefully packaged to prevent damage during transit.

This meticulous process ensures that each floating ball valve delivered to industries like petrochemical, metallurgy, and water supply & drainage, provides superior performance, energy saving due to low pressure drop, and exceptional corrosion resistance.

Technical Advantages & Performance Benefits

The inherent design and advanced manufacturing of the floating ball valve impart a range of significant technical advantages and performance benefits that are critical for modern industrial operations. These benefits translate directly into enhanced efficiency, safety, and reduced operational costs for end-users.

Key Advantages:

- Superior Sealing Performance: The fundamental principle of a floating ball valve is its self-compensating seat design. Process pressure pushes the ball against the downstream seat, creating a tighter seal as pressure increases. This positive sealing mechanism ensures zero leakage, which is paramount for safety and environmental protection, especially when handling hazardous or valuable fluids.

- Low Operating Torque: The absence of trunnion supports means the ball effectively floats, resulting in lower friction between the ball and seats during actuation. This translates to significantly lower operating torque compared to trunnion-mounted designs, allowing for smaller actuators and reduced energy consumption for automated systems. This contributes to measurable energy saving.

- Compact Design: Due to its simpler internal structure, a floating ball valve typically offers a more compact footprint than other valve types, particularly in smaller sizes. This is advantageous in installations where space is at a premium, such as in skid-mounted units or complex piping arrangements.

- Bidirectional Shut-off: While often optimized for primary flow direction, many modern floating ball valve designs incorporate features that allow for effective bidirectional shut-off, enhancing their versatility and applicability in diverse fluid handling systems.

- Wide Material Compatibility & Corrosion Resistance: With options for bodies in WCB, LCB, various stainless steels (CF8, CF8M, Duplex, Super Duplex), and exotic alloys like Hastelloy or Monel, these valves offer exceptional corrosion resistance across a broad spectrum of aggressive media. The choice of robust seat materials such as PEEK or Devlon further extends their chemical and temperature resilience, making a stainless steel ball float valve a go-to for many chemical process applications.

- Ease of Maintenance & Long Service Life: The straightforward design generally simplifies maintenance procedures. With proper material selection and adherence to manufacturing quality (ISO 9001, API 6D), these valves are designed for an extended service life, often exceeding 15-20 years in typical industrial applications. Regular maintenance, such as seat and seal replacement, can further extend their operational lifespan.

- Cost-Effectiveness: While initial investment might vary, the long-term total cost of ownership (TCO) for a floating ball valve is often lower due to its reliability, low maintenance requirements, and energy-efficient operation, contributing to significant operational savings over time.

Independent testing from accredited laboratories often demonstrates that valves conforming to API 6D and ISO 17292 standards consistently achieve leak rates significantly below specified maximums, underpinning their technical superiority. This empirical data reinforces the reliability and performance claims, building confidence among engineering procurement and construction (EPC) firms and end-users alike.

Application Scenarios & Target Industries

The versatility and robust performance of the floating ball valve make it an indispensable component across a broad spectrum of industries and application scenarios. Its ability to provide quick shut-off, low pressure drop, and reliable sealing in diverse fluid conditions positions it as a preferred choice for critical control points.

Target Industries:

- Oil & Gas: From upstream exploration and production to midstream transportation and downstream refining, floating ball valve are widely used for isolating process lines, emergency shut-down (ESD) systems, and utility services. Their reliable shut-off is crucial for preventing leaks of hydrocarbons.

- Petrochemical: In chemical processing plants, these valves manage the flow of various chemicals, acids, and solvents. The availability of corrosion-resistant materials, such as a stainless steel ball float valve, ensures longevity and safe operation in aggressive chemical environments.

- Power Generation: Used in both conventional thermal power plants and renewable energy facilities, floating ball valve control water, steam, and fuel lines. Their quick-acting quarter-turn operation is beneficial in systems requiring rapid isolation.

- Water & Wastewater Treatment: For managing raw water intake, treated water distribution, and wastewater processing, these valves provide reliable flow control. The small ball valve float variant is often employed in sampling lines or local instrumentation.

- Metallurgy & Mining: Handling abrasive slurries and corrosive chemicals in mining operations or high-temperature gases in metallurgical processes, specific material configurations of the floating ball valve are engineered to withstand extreme conditions.

- Pharmaceutical & Food & Beverage: For applications requiring high purity and hygienic design, stainless steel ball float valve with specific finishes are critical for preventing contamination and ensuring sterility in these sensitive industries.

Typical Application Scenarios:

- Isolation Valves: Their tight shut-off capabilities make them ideal for isolating sections of piping for maintenance or repair, ensuring worker safety and system integrity.

- Emergency Shut-down (ESD) Systems: When paired with quick-acting actuators, floating ball valve serve as crucial components in ESD systems, rapidly halting flow in emergencies to prevent catastrophic failures.

- Instrument Lines & Sampling Points: The small ball valve float variant is frequently used in instrument tubing, bypass lines, and sampling points where space is limited and precise isolation is required.

- Level Control Systems: A float operated ball valve is often employed in tanks and vessels to automatically maintain liquid levels, demonstrating the adaptability of ball valve technology to specific control functions.

- Process Flow Control: While primarily isolation valves, they can also be used for throttling in less critical applications, though dedicated control valves are preferred for precise regulation.

Customer feedback consistently highlights the reliability of these valves in maintaining system uptime and reducing unscheduled maintenance. For instance, a major chemical producer reported a 15% reduction in fugitive emissions after upgrading to high-performance floating ball valve with enhanced stem packing, underscoring their environmental and operational benefits.

Vendor Comparison & Customized Solutions

Selecting the right vendor for floating ball valve is as critical as the valve specifications themselves. The market offers a diverse range of manufacturers, each with varying capabilities, quality standards, and support services. A comprehensive vendor comparison focuses not only on price but also on critical factors such as product quality, certifications, customization capabilities, and after-sales support.

Key Factors for Vendor Comparison:

- Certifications & Standards: Verify that the vendor's products comply with international standards such as ISO 9001 (Quality Management), API 6D (Pipeline Valves), ANSI B16.34 (Valves-Flanged, Threaded, and Welding End), and potentially NACE MR0175 (Sulphide Stress Cracking Resistant Metallic Materials for Oilfield Equipment) for sour service.

- Manufacturing Capabilities: Assess the vendor's ability to perform in-house processes like casting, forging, and advanced CNC machining. This often indicates greater control over quality and lead times.

- Testing & Quality Assurance: A reputable vendor will have robust in-house testing facilities for hydrostatic, pneumatic, fugitive emission, and functional tests, along with comprehensive material traceability.

- Experience & Reputation: Longevity in the industry, a strong track record, and positive client testimonials (especially from major EPCs or end-users) are strong indicators of reliability.

- Customization & Engineering Support: The ability to provide tailored solutions for unique application requirements, supported by experienced engineering teams.

- Lead Time & Logistics: Efficiency in production and delivery, especially for large orders or urgent replacements.

- After-Sales Support & Warranty: Comprehensive warranty policies, technical support, and availability of spare parts.

Product Feature Comparison: Floating vs. Trunnion Ball Valves

| Feature | Floating Ball Valve | Trunnion Mounted Ball Valve |

|---|---|---|

| Ball Support | Ball "floats" against seats, supported by stem at top. | Ball is fixed by trunnions at top and bottom, reducing seat stress. |

| Sealing Mechanism | Process pressure pushes ball against downstream seat for sealing. | Seats are spring-loaded and pushed against the fixed ball for sealing. |

| Operating Torque | Generally lower, especially in smaller sizes. | Very low, as friction is minimized by trunnion support, ideal for large sizes/high pressures. |

| Suitable Size Range | Typically DN15 (1/2") up to DN200 (8"). | Primarily DN50 (2") and larger, up to very large diameters. |

| Pressure Class | ANSI Class 150 to 600LB (some up to 900LB). | ANSI Class 150 to 2500LB and beyond, suitable for extremely high pressures. |

| Cavity Pressure Relief | Can be an issue for certain fluids; typically requires a body relief hole. | Self-relieving seats are common, automatically releasing cavity pressure. |

| Cost | Generally more economical for smaller sizes and moderate pressures. | Higher initial cost, justified by performance in large/high-pressure applications. |

Customized Solutions:

Leading manufacturers understand that off-the-shelf solutions may not always meet unique project demands. Customization capabilities are crucial, particularly for specialized applications. This can include:

- Exotic Materials: Utilizing Hastelloy, Monel, Inconel, or Duplex/Super Duplex stainless steels for extreme corrosion or temperature resistance.

- Special Seat & Seal Materials: Beyond standard PTFE, options like PEEK, Devlon, or PCTFE for higher temperatures, abrasive media, or specific chemical compatibility.

- Cryogenic Service: Design modifications for ultra-low temperature applications, including extended bonnets and specialized packing.

- High-Temperature Service: Metal seats, graphite packing, and specific body materials to withstand elevated temperatures.

- Actuation & Automation: Integration with specific pneumatic, hydraulic, or electric actuators, including failsafe options (e.g., spring-return).

- Fugitive Emission Compliance: Enhanced stem packing designs and testing to meet stringent environmental regulations (e.g., ISO 15848-1).

Partnering with a vendor offering robust engineering support ensures that these customized solutions are precisely engineered and rigorously tested, delivering optimal performance and compliance.

Real-world Application Case Studies

The practical deployment of floating ball valve in diverse industrial settings provides tangible evidence of their reliability, efficiency, and critical role in fluid control systems. These case studies highlight their performance in overcoming specific operational challenges.

Case Study 1: Natural Gas Processing Facility

Client: A major natural gas processing company in North America.

Challenge: The client faced frequent leakage issues and high maintenance costs with existing gate valves in their gas dehydration unit, particularly at various isolation points handling high-pressure, dry natural gas. The inconsistent sealing performance led to product loss and safety concerns.

Solution: Implemented Q41F-600LB ANSI floating ball valve with high-performance PEEK seats and SS316 body/ball construction. These valves were chosen for their proven tight shut-off capabilities and resistance to dry gas abrasion. The robust design allowed for reliable operation at line pressures up to 100 barg.

Outcome: After 3 years of operation, the facility reported a 99% reduction in valve-related leakage incidents and an estimated 20% decrease in annual maintenance expenditure for the replaced valves. The quick quarter-turn operation also improved operational response times during process upsets. This directly demonstrated the superior reliability and enhanced safety provided by the chosen floating ball valve solutions.

Case Study 2: Chemical Plant Acid Transfer System

Client: A specialty chemicals manufacturer operating a plant with highly corrosive media.

Challenge: The transfer lines for concentrated sulfuric acid (H2SO4) and hydrochloric acid (HCl) experienced rapid degradation of valve components, leading to premature failures and hazardous conditions. Standard stainless steel valves were insufficient for long-term service.

Solution: Customized stainless steel ball float valve were supplied, featuring Hastelloy C-276 body and ball materials for exceptional corrosion resistance, coupled with specialized modified PTFE seats and packing. The valves were designed to meet ANSI Class 300LB requirements for the process pressure.

Outcome: The customized Hastelloy floating ball valve demonstrated superior resistance to the aggressive acids, extending valve service life from an average of 6-8 months to over 5 years. This resulted in a significant improvement in plant safety, reduced environmental risk, and a substantial decrease in unscheduled downtime and replacement costs. The specific material combination proved vital for the challenging application.

Case Study 3: Municipal Water Treatment Plant

Client: A large municipal water treatment facility managing potable water distribution.

Challenge: The plant required reliable, easy-to-operate isolation valves for various bypass lines and small utility connections within their complex network. Space constraints and the need for quick shut-off without significant pressure loss were key considerations. Existing globe valves were cumbersome and created excessive pressure drop.

Solution: The facility standardized on small ball valve float in sizes ranging from 1/2" to 2", with SS304 body and ball, and PTFE seats. These compact valves were ideal for the tight spaces and provided the necessary quick isolation for maintenance and operational adjustments. In addition, several float operated ball valve were integrated into storage tank level control systems, providing automated fill-stop functions with high accuracy.

Outcome: The adoption of these floating ball valve led to improved operational efficiency, easier maintenance access due to compact size, and enhanced reliability in critical utility and control functions. The tight shut-off ensured no water wastage from bypass lines, contributing to overall resource management goals.

Ensuring Trust: Certifications, Partnerships & Support

Trust is paramount in B2B relationships, especially when dealing with critical components like the floating ball valve. A reputable manufacturer not only delivers high-quality products but also demonstrates authoritativeness through industry certifications, strong partnerships, and unwavering support infrastructure.

Authoritative Credentials:

- ISO 9001:2015 Certification: Demonstrates a commitment to quality management systems throughout design, development, production, installation, and service. This ensures consistent product quality for every floating ball valve.

- API 6D Monogram License: For pipeline valves, this certification signifies compliance with API's stringent standards for design, manufacturing, and testing, crucial for the oil and gas industry.

- CE Marking (PED 2014/68/EU): Essential for pressure equipment sold within the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- Fugitive Emission Certifications (ISO 15848-1, API 622/624): For valves designed to minimize stem leakage, addressing environmental concerns and regulatory requirements.

- NACE MR0175 / ISO 15156 Compliance: For materials used in sour service environments (containing H2S), preventing sulfide stress cracking.

Our decades of service in the valve industry, backed by an extensive portfolio of satisfied clients ranging from multinational energy corporations to specialized chemical producers, further underscore our authoritative standing.

Trustworthiness & Support Commitments:

- Lead Time & Fulfillment: We maintain efficient manufacturing and supply chain processes to ensure competitive lead times, typically ranging from 4-8 weeks for standard floating ball valve configurations, with expedited options available for urgent requirements. Detailed project timelines are provided for customized orders.

- Warranty Commitments: All our floating ball valve products are backed by a comprehensive 12-month warranty from the date of commissioning or 18 months from the date of shipment, whichever comes first. This covers manufacturing defects and material failures under normal operating conditions.

- Customer Support & After-Sales Service: Our dedicated technical support team comprises experienced engineers available to assist with product selection, installation guidance, troubleshooting, and maintenance advice. We offer readily available spare parts and facilitate on-site technical support when required, ensuring minimal downtime and sustained operational efficiency for our clients.

- Documentation: Comprehensive documentation, including material test reports, dimensional drawings, pressure test certificates, and operation & maintenance manuals, accompanies every shipment, ensuring full traceability and compliance.

Frequently Asked Questions (FAQ)

Here are answers to common questions regarding floating ball valve selection, operation, and maintenance, providing quick access to essential information for B2B decision-makers and engineers.

-

Q1: What are the primary advantages of a floating ball valve over other valve types like gate or globe valves?

A1: Floating ball valve offer quick quarter-turn operation, superior tight shut-off capabilities, minimal pressure drop leading to energy saving, and a more compact design. They are excellent for isolation services, whereas gate valves are slower and globe valves induce significant pressure drop. -

Q2: When should I choose a stainless steel ball float valve?

A2: A stainless steel ball float valve (e.g., SS304, SS316, Duplex) is recommended for applications involving corrosive media, high purity requirements (like food & beverage, pharmaceuticals), or when enhanced temperature and pressure resistance are needed compared to carbon steel. -

Q3: Can a floating ball valve be used for throttling or flow regulation?

A3: While floating ball valve are primarily designed for on/off (isolation) service, they can be used for some limited throttling. However, continuous throttling can cause excessive wear on the ball and seats, potentially compromising their tight shut-off capability. For precise flow regulation, dedicated control valves are generally preferred. -

Q4: What is the typical service life of a Q41F ANSI Floating Ball Valve?

A4: With proper material selection, correct installation, and routine maintenance, a high-quality Q41F ANSI floating ball valve can achieve a service life of 15 to 20 years or more in typical industrial applications. Factors like operating frequency, fluid abrasiveness, and temperature cycling can influence this. -

Q5: What are the considerations for selecting seat materials for a floating ball valve?

A5: Seat material selection is crucial and depends on operating temperature, fluid compatibility, pressure, and the presence of abrasives. Common options include PTFE (for general purpose, up to 200°C), RPTFE (reinforced PTFE for higher pressure/temperature), PPL (for higher temperatures), and PEEK (for extreme temperatures, high pressure, and chemical resistance). -

Q6: Are there specific considerations for a small ball valve float in terms of installation?

A6: For a small ball valve float, installation generally follows standard practices. However, ensure proper thread sealant for threaded connections and correct flange alignment for flanged versions to prevent stress on the piping. Given their compact size, they are often used in instrumentation lines where careful positioning is required.

Conclusion

The floating ball valve, epitomized by the Q41F ANSI series, represents a critical element in modern industrial fluid control systems. Its robust design, characterized by efficient self-sealing, low operating torque, and high flow capacity, ensures reliable and safe operations across diverse and demanding applications. From the intricate requirements of petrochemical processing to the vital functions in water treatment, these valves deliver consistent performance, contributing significantly to operational efficiency, energy conservation, and environmental compliance.

With continuous advancements in materials science and manufacturing precision, the versatility of the floating ball valve continues to expand, offering tailored solutions for even the most challenging fluid handling scenarios. By understanding its technical specifications, application advantages, and the importance of authoritative vendor selection, industries can harness the full potential of these essential control devices to optimize their processes and ensure long-term operational integrity.

References

- API Specification 6D, Specification for Pipeline Valves. American Petroleum Institute, Washington D.C.

- ISO 17292:2015, Metal ball valves for petroleum, petrochemical and allied industries. International Organization for Standardization.

- ASME B16.34-2020, Valves—Flanged, Threaded, and Welding End. American Society of Mechanical Engineers.

- "Advances in Industrial Valve Technology for Sustainable Operations," Journal of Process Control Engineering, Vol. 15, No. 3, 2022.

- "Material Selection for Corrosive Service: A Comprehensive Review for Process Valves," International Journal of Chemical Engineering and Applications, Vol. 10, No. 2, 2021.

-

3 types of check valves maintenance tipsNewsAug.23,2025

-

Ball valves types with trunnion mounted designNewsAug.23,2025

-

Butterfly valve company production capabilitiesNewsAug.23,2025

-

Fisher globe valve technical specificationsNewsAug.23,2025

-

Types of gaskets for flanges selection guideNewsAug.23,2025

-

Wedge gate valve suppliers quality standardsNewsAug.23,2025

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025