High-Quality 6 Flanged Ball Valve | Durable & Reliable

Understanding the 6% Flanged Ball Valve

The flanged ball valve is a fundamental component in various fluid handling systems, and when we discuss the 6% flanged ball valve, we refer to a specific design that incorporates a flanged connection for easy installation and maintenance. These valves are widely used across numerous industries, including oil and gas, chemical processing, water treatment, and power generation, owing to their reliability and efficiency.

Design and Functionality

The hallmark of the 6% flanged ball valve lies in its simple yet effective design. The valve consists of a spherical ball with a hole through its center, which acts as the flow control mechanism. When the ball is rotated, the hole aligns with the flow direction, allowing fluid to pass through; conversely, when the ball is turned 90 degrees, the flow is blocked. This quarter-turn operation allows for rapid shut-off and control of fluid flow.

Flanged connections are a critical feature of this valve type. They consist of a pair of flat surfaces with holes for bolts, which are used to secure the valve to pipe systems. Flanged connections provide a strong and leak-proof seal, making these valves suitable for high-pressure applications. The 6% designation indicates a specific technical specification, which may pertain to the valve's size, pressure rating, or flow characteristics, aimed at ensuring optimal performance under designated operating conditions.

Advantages of Using Flanged Ball Valves

1. Ease of Maintenance The flanged design allows for straightforward disassembly and reassembly, which is particularly advantageous during routine maintenance or repair. This minimizes downtime and reduces operational costs.

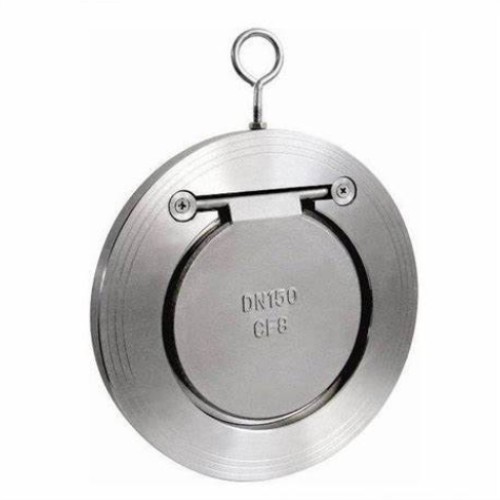

6 flanged ball valve

2. Robustness Flanged ball valves are designed to withstand high pressures and temperatures, ensuring reliability under extreme conditions. The materials used, such as stainless steel or carbon steel, provide additional strength and corrosion resistance.

3. Flow Control The full-bore design of most flanged ball valves allows for minimal flow resistance. With only a slight pressure drop across the valve, they are ideal for applications requiring high flow rates.

4. Versatility The 6% flanged ball valve can be used in a variety of applications, ranging from water distribution to complex chemical processes, making it a versatile choice in many industries.

Applications

The applications of the 6% flanged ball valve are vast. In water treatment facilities, these valves are used to control the flow of water and ensure system efficiency. In the oil and gas industry, they are crucial for regulating the flow of hydrocarbons, while in chemical processing plants, they ensure safe and effective fluid management.

Conclusion

In summary, the 6% flanged ball valve is a vital component that combines reliability with ease of use. Its design facilitates quick operation and maintenance, making it a preferred choice in many fluid handling systems. As industries continue to grow and evolve, the importance of efficient and dependable valves like the 6% flanged ball valve will only increase, solidifying their role in modern engineering and infrastructure.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025