Čvn . 16, 2024 11:27

Back to list

4 inch wafer valve check

The Crucial Role of 4 Inch Wafer Check Valve in Semiconductor Manufacturing

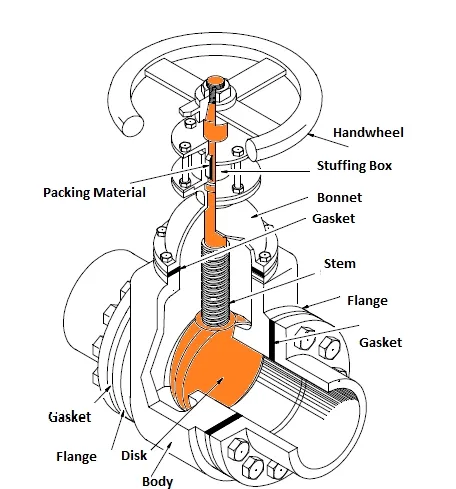

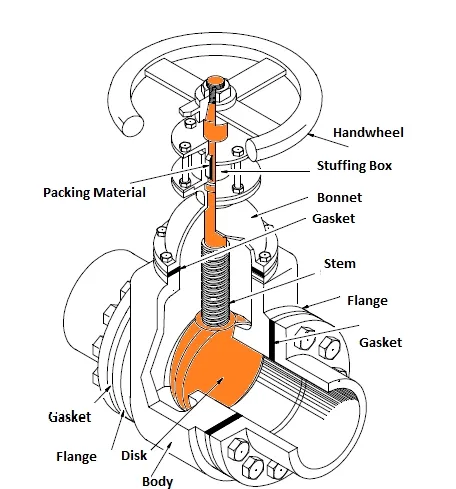

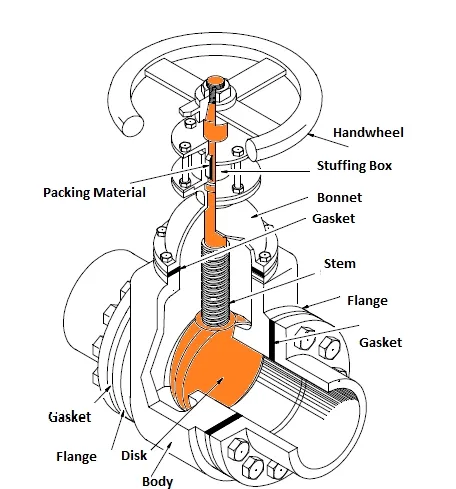

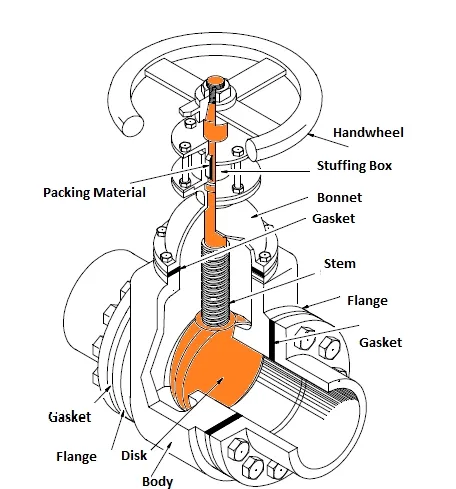

In the realm of semiconductor manufacturing, precision and reliability are paramount. One such critical component that ensures the smooth flow of materials and prevents contamination is the 4-inch wafer check valve. This valve, with its precise design and functionality, plays a vital role in maintaining the high standards of cleanliness and efficiency required in the semiconductor industry.

The 4-inch wafer check valve is specifically engineered to handle the unique demands of the semiconductor industry. It features a compact size, making it ideal for integration into existing production lines without the need for significant modifications. This compactness not only saves space but also reduces the risk of material waste during installation and maintenance.

One of the key advantages of the 4-inch wafer check valve is its ability to maintain a consistent flow rate. This is crucial in ensuring that the process chambers receive the precise amount of gas or liquid needed for optimal performance. By maintaining a steady flow, the valve helps to prevent fluctuations that can lead to inconsistencies in product quality.

Furthermore, the valve's durable construction ensures long-term reliability

Furthermore, the valve's durable construction ensures long-term reliability Furthermore, the valve's durable construction ensures long-term reliability

Furthermore, the valve's durable construction ensures long-term reliability

Furthermore, the valve's durable construction ensures long-term reliability

Furthermore, the valve's durable construction ensures long-term reliability 4 inch wafer check valve. Made from high-quality materials, it can withstand the harsh conditions commonly found in semiconductor manufacturing environments, including high temperatures and corrosive chemicals. This durability reduces the frequency of maintenance and replacement, resulting in cost savings and increased productivity.

In addition to its functional benefits, the 4-inch wafer check valve also offers excellent chemical resistance. This feature is particularly important in processes that involve the use of aggressive chemicals, as it prevents these chemicals from reacting with the valve material and causing damage. This not only extends the valve's lifespan but also ensures the integrity of the process fluids.

Overall, the 4-inch wafer check valve is an indispensable tool in the semiconductor manufacturing process. Its compact size, consistent flow rate, durability, and chemical resistance make it an ideal choice for ensuring the smooth operation of production lines and maintaining the highest standards of product quality. As the demand for advanced semiconductor devices continues to grow, the importance of reliable and efficient valve technology will only become more apparent.

4 inch wafer check valve. Made from high-quality materials, it can withstand the harsh conditions commonly found in semiconductor manufacturing environments, including high temperatures and corrosive chemicals. This durability reduces the frequency of maintenance and replacement, resulting in cost savings and increased productivity.

In addition to its functional benefits, the 4-inch wafer check valve also offers excellent chemical resistance. This feature is particularly important in processes that involve the use of aggressive chemicals, as it prevents these chemicals from reacting with the valve material and causing damage. This not only extends the valve's lifespan but also ensures the integrity of the process fluids.

Overall, the 4-inch wafer check valve is an indispensable tool in the semiconductor manufacturing process. Its compact size, consistent flow rate, durability, and chemical resistance make it an ideal choice for ensuring the smooth operation of production lines and maintaining the highest standards of product quality. As the demand for advanced semiconductor devices continues to grow, the importance of reliable and efficient valve technology will only become more apparent.

Furthermore, the valve's durable construction ensures long-term reliability

Furthermore, the valve's durable construction ensures long-term reliability

Furthermore, the valve's durable construction ensures long-term reliability

Furthermore, the valve's durable construction ensures long-term reliability 4 inch wafer check valve. Made from high-quality materials, it can withstand the harsh conditions commonly found in semiconductor manufacturing environments, including high temperatures and corrosive chemicals. This durability reduces the frequency of maintenance and replacement, resulting in cost savings and increased productivity.

In addition to its functional benefits, the 4-inch wafer check valve also offers excellent chemical resistance. This feature is particularly important in processes that involve the use of aggressive chemicals, as it prevents these chemicals from reacting with the valve material and causing damage. This not only extends the valve's lifespan but also ensures the integrity of the process fluids.

Overall, the 4-inch wafer check valve is an indispensable tool in the semiconductor manufacturing process. Its compact size, consistent flow rate, durability, and chemical resistance make it an ideal choice for ensuring the smooth operation of production lines and maintaining the highest standards of product quality. As the demand for advanced semiconductor devices continues to grow, the importance of reliable and efficient valve technology will only become more apparent.

4 inch wafer check valve. Made from high-quality materials, it can withstand the harsh conditions commonly found in semiconductor manufacturing environments, including high temperatures and corrosive chemicals. This durability reduces the frequency of maintenance and replacement, resulting in cost savings and increased productivity.

In addition to its functional benefits, the 4-inch wafer check valve also offers excellent chemical resistance. This feature is particularly important in processes that involve the use of aggressive chemicals, as it prevents these chemicals from reacting with the valve material and causing damage. This not only extends the valve's lifespan but also ensures the integrity of the process fluids.

Overall, the 4-inch wafer check valve is an indispensable tool in the semiconductor manufacturing process. Its compact size, consistent flow rate, durability, and chemical resistance make it an ideal choice for ensuring the smooth operation of production lines and maintaining the highest standards of product quality. As the demand for advanced semiconductor devices continues to grow, the importance of reliable and efficient valve technology will only become more apparent. Latest news

-

3 types of check valves maintenance tipsNewsAug.23,2025

-

Ball valves types with trunnion mounted designNewsAug.23,2025

-

Butterfly valve company production capabilitiesNewsAug.23,2025

-

Fisher globe valve technical specificationsNewsAug.23,2025

-

Types of gaskets for flanges selection guideNewsAug.23,2025

-

Wedge gate valve suppliers quality standardsNewsAug.23,2025

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025