china dn200 gate valve

Understanding the China DN200 Gate Valve

The DN200 gate valve is a critical component in various industrial applications, particularly in fluid control systems. Designed for versatility and efficiency, this valve exemplifies the innovative engineering prevalent in the Chinese manufacturing sector. While DN stands for Diamètre Nominal, which is a standard measurement in millimeters, specifying DN200 indicates that the valve has a nominal diameter of 200 millimeters or approximately 8 inches.

Key Features

1. Design and Construction The DN200 gate valve typically features a robust and durable design that allows it to withstand high-pressure conditions. Made from high-quality materials such as stainless steel, cast iron, and carbon steel, these valves are engineered to provide longevity and reliability. The gate valve operates by lifting a metal gate out of the path of the fluid, thus allowing for unobstructed flow when fully opened.

2. Flow Control Gate valves are particularly effective for on/off control rather than throttling, making them ideal for applications where a minimal flow restriction is essential. The DN200 size is well-suited for large pipelines transporting water, oil, gas, and other industrial fluids.

3. Applications These valves are widely used across various sectors, including water supply systems, petrochemical industries, power plants, and HVAC systems. Their ability to handle a wide range of temperatures and pressures makes them suitable for both hot and cold fluids.

4. Installation and Maintenance The installation of a DN200 gate valve is generally straightforward, thanks to its flanged connections, which allow for easy mounting to pipelines. Maintenance is also simplified, as these valves often feature replaceable seats and packing, extending their service life and reducing total operational costs.

china dn200 gate valve

Advantages of China DN200 Gate Valves

1. Cost-Effectiveness One of the primary reasons for the widespread adoption of China-manufactured DN200 gate valves is their cost-effectiveness. With efficient production processes and abundant raw materials, Chinese manufacturers can offer competitive pricing without compromising on quality.

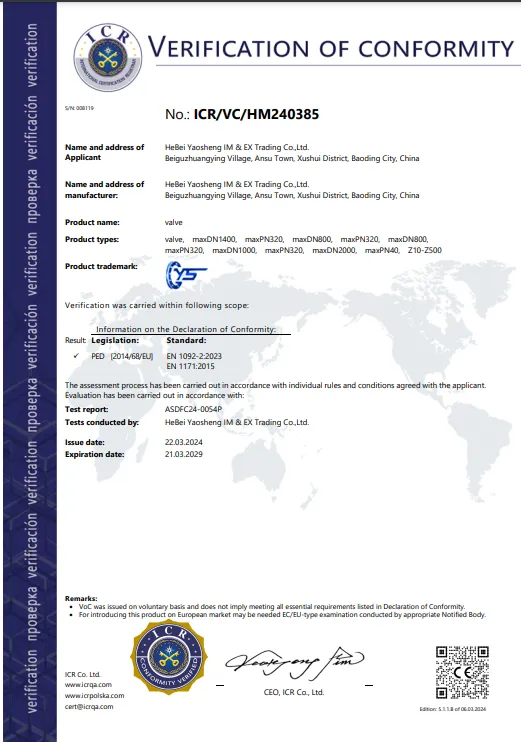

2. Quality Standards Many Chinese manufacturers adhere to international standards such as ISO 9001, ensuring that their products meet stringent quality control measures. This adherence not only enhances the reliability of the valves but also boosts confidence among global buyers.

3. Technological Advancements Continuous investment in research and development has led Chinese valve manufacturers to embrace cutting-edge technology. Innovations such as enhanced sealing techniques and corrosion-resistant coatings increase the performance and durability of DN200 gate valves.

4. Availability Given the scale of the manufacturing operations in China, DN200 gate valves are readily available in various specifications and variants, catering to the specific needs of diverse applications.

Conclusion

In summary, the China DN200 gate valve represents a blend of quality, efficiency, and cost-effectiveness, making it a preferred choice for engineers and procurement managers alike. Its robust design, ability to handle large volumes of fluid, and ease of maintenance contribute to its popularity in various industrial sectors. As industries continue to evolve and demand more sophisticated fluid control solutions, the DN200 gate valve stands out as an indispensable component in modern infrastructure. Whether for construction, petrochemical processing, or municipal water systems, the DN200 gate valve is poised to meet the fluid control challenges of the future.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025