Advanced Cryogenic Globe Valve Solutions for Efficient Fluid Control in China

Understanding China Cryogenic Globe Valves A Comprehensive Overview

Cryogenic globe valves are essential components in various industries, including natural gas, chemicals, and aerospace, where handling materials at extremely low temperatures is a common requirement. In China, the production and application of cryogenic globe valves have seen significant advancements, establishing the country as a key player in the global valve market. This article aims to delve into the characteristics, applications, and manufacturing innovations of cryogenic globe valves in China.

What is a Cryogenic Globe Valve?

A cryogenic globe valve is a type of valve that regulates flow in a pipeline by using a movable disk (the globe) to obstruct the passage of fluid. These valves are specifically designed to function effectively in low-temperature applications, typically below -196 degrees Celsius (approximately -320 degrees Fahrenheit). The construction of cryogenic globe valves typically involves specialized materials that can withstand extreme temperatures without compromising their structural integrity or performance.

Key Features and Advantages

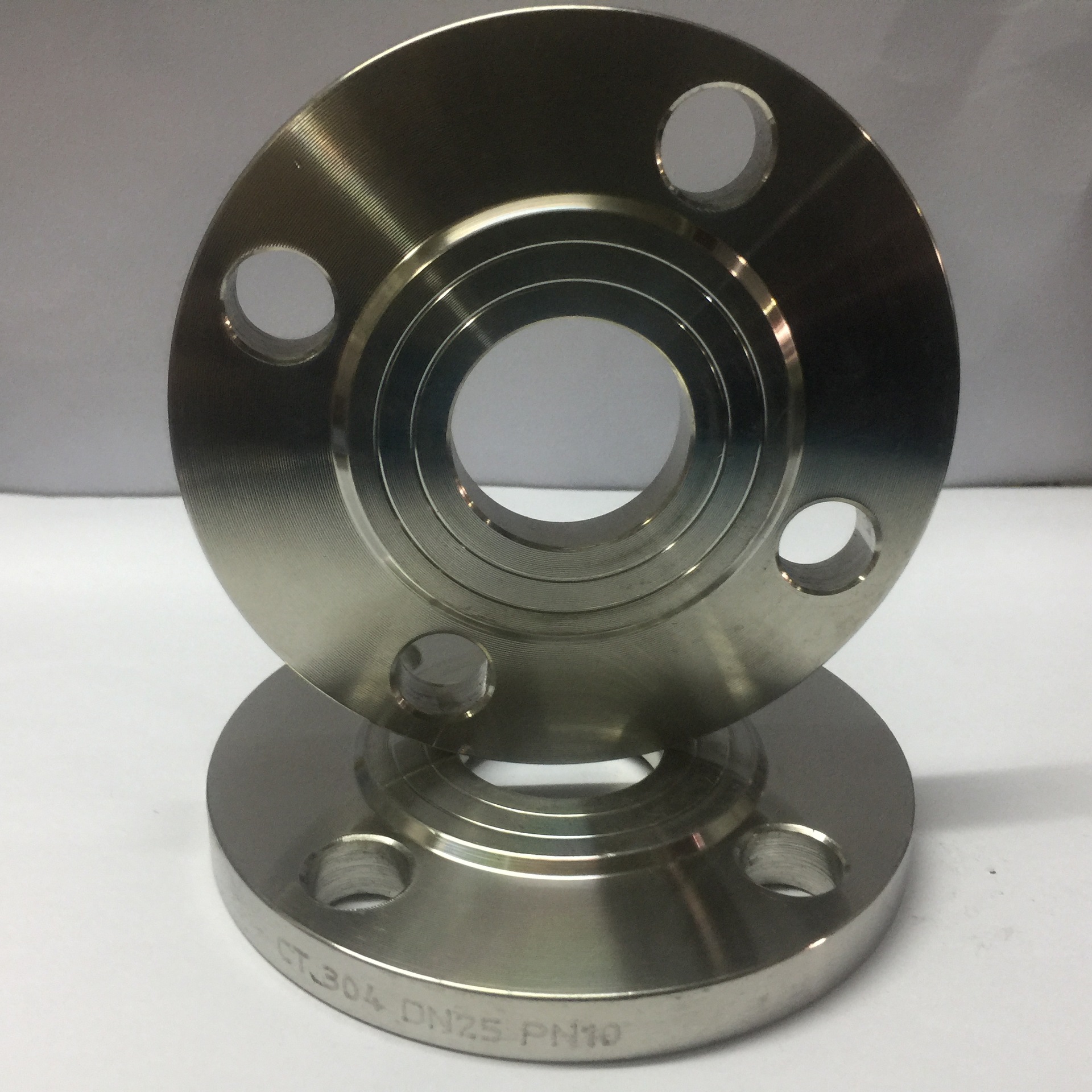

1. Design and Construction Cryogenic globe valves are engineered with robust materials such as stainless steel, carbon steel, or special alloys that exhibit excellent low-temperature toughness. Their design is often compact, allowing for installation in spaces where traditional valves may not fit.

2. Operational Efficiency These valves provide precise flow control and minimal pressure drop, essential characteristics for maintaining optimal performance in cryogenic systems. Their design minimizes turbulence and allows for smoother operation.

3. Safety One of the critical aspects of cryogenic applications is safety. Cryogenic globe valves feature a fail-safe design, ensuring that in the event of extraordinary conditions, the valve can take the necessary measures to prevent leaks or other hazards.

4. Versatile Application These valves are widely used in various sectors, such as liquefied natural gas (LNG), medical gas systems, and superconductor applications, contributing to their importance in modern engineering and technology.

The Role of China in the Global Valve Market

China has emerged as a significant player in the production of cryogenic globe valves, thanks to its extensive manufacturing capabilities and growing expertise in valve technology. The country serves both domestic and international markets, exporting cryogenic valves to regions such as North America, Europe, and Asia.

china cryogenic globe valve

1. Manufacturing Innovations Chinese manufacturers continuously improve their production processes by adopting advanced technologies such as computer-aided design (CAD) and automated manufacturing systems. These innovations enhance precision engineering, ensure consistent quality, and reduce production costs.

2. Research and Development Investment in R&D is crucial for companies in China to maintain competitive advantages. Chinese valve manufacturers are increasingly collaborating with research institutions to develop new materials and designs that can enhance the performance of cryogenic valves in demanding environments.

3. Compliance with Standards To meet international market requirements, Chinese manufacturers invest in certifications and compliance with global standards such as ASME B16.34 for valve design and fabrication. This commitment to quality ensures that their products can compete with those from established manufacturers worldwide.

Applications of Cryogenic Globe Valves in Various Industries

Cryogenic globe valves find wide-ranging applications across different sectors

- Natural Gas Industry In the LNG sector, cryogenic globe valves control the flow of liquefied gas during storage and transportation, ensuring safety and efficiency in handling natural gas.

- Medical Applications Cryogenic valves are crucial in transporting medical gases, such as oxygen and nitrous oxide, at low temperatures, ensuring that the gases remain in a liquid state until needed.

- Aerospace The aerospace industry utilizes cryogenic globe valves in the management of cryogenic fuels, such as liquid hydrogen and liquid oxygen, vital for rocket propulsion.

Conclusion

The demand for cryogenic globe valves in China and worldwide is on the rise, driven by advancements in technology and an increasing need for efficient flow control in low-temperature applications. As Chinese manufacturers continue to innovate and expand their capabilities, they will undoubtedly play a pivotal role in shaping the future of cryogenic valve technology. With a focus on quality, safety, and operational efficiency, cryogenic globe valves are set to remain an indispensable component in various industries, ensuring processes run smoothly and safely in an increasingly demanding environment.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025