Top Uni Flange Manufacturers for Quality and Performance in the Industry

Understanding UNI Flange Manufacturers A Comprehensive Overview

Flanges are critical components used in various engineering and industrial applications. They serve as connection points between piping systems, valves, pumps, and other equipment. Among the various standards and types of flanges available in the market, UNI flanges, which adhere to the Italian standard (UNI – Unità Nazionale Italiana), are commonly utilized across diverse sectors, including oil and gas, water treatment, and chemical processing. Understanding the manufacturing processes and quality standards of UNI flanges can greatly enhance one's ability to select the right products for specific applications.

What are UNI Flanges?

UNI flanges are characterized by their specific design and dimensions as stipulated by the UNI standards. These standards ensure uniformity in the manufacturing process, which is crucial for ensuring compatibility and safety in piping systems. The UNI standards include specifications for different types of flanges, such as flat, raised face, slip-on, weld-neck, and blind flanges, each tailored for specific applications.

Importance of UNI Flanges

One of the most significant advantages of using UNI flanges is their uniformly defined dimensions. This standardization facilitates ease of assembly and disassembly of piping systems, which is essential for maintenance and repairs. Additionally, UNI flanges are engineered to withstand high pressures and temperatures, making them ideal for many industrial applications. Their reliability contributes to the overall safety and efficiency of the piping systems in which they are used.

Selecting a UNI Flange Manufacturer

When it comes to selecting a UNI flange manufacturer, several factors should be considered

uni flange manufacturers

1. Quality Assurance Reputable manufacturers often adhere to recognized quality assurance protocols, such as ISO 9001, which ensures that their products meet international quality standards. Certifications can be an indication of a manufacturer’s commitment to quality and reliability.

2. Materials Used Flanges can be manufactured from various materials, including carbon steel, stainless steel, and alloy steels. It's crucial to choose a manufacturer that uses high-quality materials appropriate for the intended application, considering factors like corrosion resistance and strength.

3. Manufacturing Processes The methods employed in the production of UNI flanges can significantly influence their quality. Techniques such as forging, casting, and machining should be understood. Manufacturers who utilize advanced technologies and processes can often produce flanges that meet stringent quality and performance standards.

4. Experience and Reputation A manufacturer’s track record can provide insights into their reliability and expertise. Established manufacturers with a long history in the industry are likely to have the experience necessary to meet customer demands and specifications.

5. Custom Solutions Depending on the application requirements, sometimes standard flanges may not be sufficient. A good manufacturer should offer customization options to accommodate unique specifications, ensuring a perfect fit in various applications.

6. Customer Support Strong customer service is essential. Manufacturers who offer comprehensive support, including technical assistance and after-sales service, demonstrate a commitment to customer satisfaction.

Conclusion

In conclusion, UNI flanges are indispensable components across various industrial sectors due to their standardization and reliability. Selecting the right UNI flange manufacturer involves evaluating their quality assurance practices, material specifications, manufacturing processes, industry experience, and customer support. By making informed choices, industries can ensure the integrity and performance of their piping systems, ultimately leading to improved safety and operational efficiency. Whether for new projects or replacement parts, aligning with a reputable UNI flange manufacturer is crucial for successful industrial operations.

-

3-types-of-check-valves-maintenance-tipsNewsAug.23,2025

-

ball-valves-types-with-trunnion-mounted-designNewsAug.23,2025

-

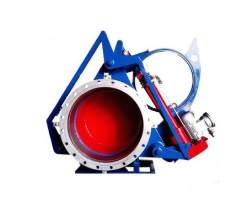

butterfly-valve-company-production-capabilitiesNewsAug.23,2025

-

fisher-globe-valve-technical-specificationsNewsAug.23,2025

-

types-of-gaskets-for-flanges-selection-guideNewsAug.23,2025

-

wedge-gate-valve-suppliers-quality-standardsNewsAug.23,2025

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025