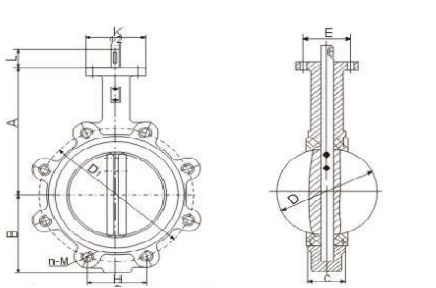

Lug Type Butterfly Valve Dimensions

| Medium | temperature: ≤80 ℃ |

| Medium: | water, oil |

| Caliber: | DN50-600 |

| Pressure: | 1.0-1.6mpa |

| Body material: | gray cast iron / nodular cast iron / carbon steel |

| Connection method: | Wafer type |

| Standard: | National Standard, American Standard |

PRODUKTUAREN PARAMETROAK:

| Zatiaren izena | Materiala | ||

| Balbula gorputza | Gray Cast Iron / Ductile Iron / WCB | ||

| Tximeleta | Burdina harikorra / SS | ||

| Balbula-ardatza | Karbonozko altzairua |

||

| Zigilatzeko eraztuna | EPDM/NBR/PTFE |

| eredua | Presio nominala (LB) |

probako presioa (mpa) | tenperatura egokia | Euskarri aplikagarria | |||||

| indarra | zigilua | ||||||||

| LTD71X-10 | 1.0 | 1.50 | 1.10 | ≤80℃ | Water, oil | ||||

| LTD371X-10 | |||||||||

| LTD71X-16 | 1.6 | 2.40 | 1.80 | ≤80℃ | Water, oil | ||||

| LTD371X-16 | |||||||||

| eredua | Diametro nominala (mm) |

tamaina (mm) | |||||||

| D | D1 | H | n-φ | C | |||||

| LTD71X-10/16 | 50 | 52.9 | 125 | 88.38 | 4-M16 | 42 | |||

| 65 | 64.5 | 145 | 102.54 | 4-M16 | 44.7 | ||||

| 80 | 78.8 | 160 | 61.23 | 8-φM16 | 45.2 | ||||

| 100 | 104 | 180 | 68.88 | 8-φM16 | 52.1 | ||||

| 125 | 123.3 | 210 | 80.36 | 8-φM16 | 54.4 | ||||

| 150 | 155.6 | 240 | 91.84 | 8-φM20 | 55.8 | ||||

| 200 | 202.5 | 295 | 112.89 76.5 |

8-φM20 12-φM24 |

60.6 | ||||

| 250 | 250.5 | 350 355 |

90.59 91.88 |

12-φM20 12-φM24 |

65.6 | ||||

| 300 | 301.6 | 400 410 |

103.52 106.12 |

12-φM20 12-φM24 |

76.9 | ||||

| 50 | 333.3 | 460 470 |

89.74 91.69 |

16-φM20 16-φM24 |

76.5 | ||||

| 400 | 389.6 | 515 525 |

100.48 102.42 |

16-φM24 16-φM27 |

86.5 | ||||

PRODUCT ADVANTAGES:

Application: This valve is mainly used for shut-off valves, and it can also be designed to have the function of regulating or shut-off and regulating.

1. We have Sand or Precision casting technology, So we can as your drawing design and production.

2. Customers' logos are available cast on the valve body.

3. All our casting with the tempering procedure before Processing.

4. Use the CNC lathe during the whole process.

5. The disc sealing surface uses plasma welding machine welding

6. Every valve must be tested before delivery from the factory, only qualified ones can be shipped.

7. The kind valve we usually use Wooden cases to package, We also can according to

bezeroen eskaera zehatzak.

COMPANY ADVANTAGES:

-

1. We have been a manufacturer Since 1992.

1. We have been a manufacturer Since 1992. -

2. CE, API, ISO approved.

2. CE, API, ISO approved. -

3. Fast delivery.

3. Fast delivery. -

4. Low price with high quality.

4. Low price with high quality. -

5. Professional work Team!

5. Professional work Team!

Lug Type Butterfly Valve Installation

First and foremost, understanding the anatomy of a lug butterfly valve is crucial before diving into the installation process. Unlike a wafer butterfly valve, which is sandwiched between two pipe flanges, a lug butterfly valve has threaded inserts on each side that allow for easy installation using bolts. This design feature not only simplifies the installation process but also enhances the valve's stability and reliability in high-pressure environments.

When it comes to installing a lug butterfly valve, proper alignment is key to ensuring optimal performance. The valve should be positioned symmetrically between the two flanges, with the shaft in a vertical orientation to prevent any stress or strain on the valve components. Tightening the bolts gradually and evenly across the flanges will help create a secure and leak-free seal, minimizing the risk of valve failure due to misalignment or uneven pressure distribution.

Moreover, applying the right amount of torque to the bolts is essential for maintaining the integrity of the lug butterfly valve during operation. Over-tightening can distort the valve body and lead to premature wear, while under-tightening can result in leakage and inefficiency. Consulting the manufacturer's guidelines for recommended torque values and using a torque wrench to achieve the desired tension will ensure proper installation and long-term reliability of the valve.

Wafer Vs Lug Butterfly Valve

Lug butterfly valves are designed with threaded inserts on both sides of the valve body, allowing for easy installation and maintenance. These valves are ideal for applications where there is a need for a secure connection between the valve and the piping system. The lug design also provides added support and stability, making it suitable for high-pressure applications. Additionally, lug butterfly valves can be easily removed from the pipeline without affecting the rest of the system, making maintenance and repairs hassle-free.

On the other hand, wafer-type butterfly valves are thinner in profile compared to lug-type valves and are sandwiched between two flanges using bolts. This design eliminates the need for additional flanges, making wafer-type valves more compact and lightweight. They are ideal for applications where space is limited and weight is a concern. Wafer-type butterfly valves are also easier and quicker to install due to their simple design, making them a cost-effective option for many industrial applications.

In terms of performance, both lug and wafer-type butterfly valves offer reliable and efficient flow control. However, the decision between the two types ultimately depends on the specific requirements of the application. If you are looking for a robust and secure valve that can handle high pressures, a lug-type butterfly valve may be the better option. On the other hand, if space and weight are a concern, a wafer-type butterfly valve may be more suitable for your needs.