helmi . 13, 2025 00:10

Back to list

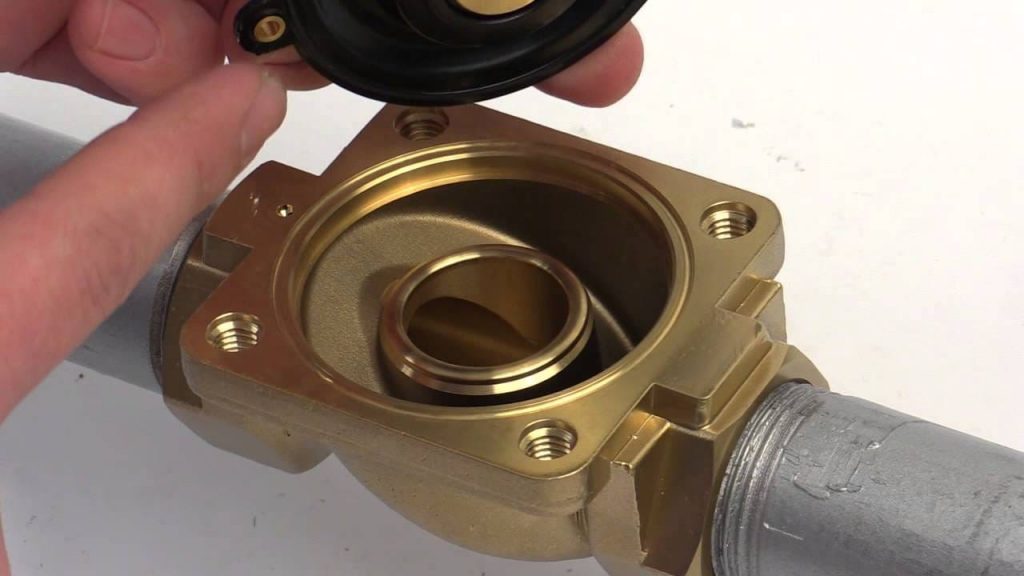

1 4 stainless needle valve

Angle needle valves are an integral component in various industrial and commercial applications, renowned for their precision in controlling fluid flow. Unlike traditional valves, angle needle valves offer meticulous regulation that makes them indispensable in systems requiring fine adjustment.

Authoritativeness in the realm of angle needle valves is often demonstrated through compliance with both national and international standards. Valves that meet the stringent requirements set by bodies like the American Society of Mechanical Engineers (ASME) or the International Organization for Standardization (ISO) exhibit a level of quality and safety that buyers can trust. Industry leaders often set benchmarks in valve technology, innovating in areas such as flow efficiency, sealing technology, and ergonomic design to enhance user experience while adhering to these authoritative standards. Trustworthiness in the context of angle needle valves is established through a track record of safety and efficiency. Manufacturers often conduct rigorous testing procedures to ensure each valve meets the required specifications without failure. Customer testimonials and long-term warranties offer additional assurance of a product's reliability. Trustworthy brands also engage in transparent communication with customers, providing detailed usage guidelines and after-sales support to foster confidence in their products. In conclusion, the value of angle needle valves lies in their ability to deliver precise fluid control across a myriad of settings. Users who rely on their performance appreciate the exactitude and reliability that these components bring to their operations. The quality assurance and adherence to industry standards reinforce their position as a trusted tool in both routine and specialized situations. Whether in high-pressure gas systems, lab environments, or fluid power applications, angle needle valves provide the level of control necessary to achieve optimal outcomes.

Authoritativeness in the realm of angle needle valves is often demonstrated through compliance with both national and international standards. Valves that meet the stringent requirements set by bodies like the American Society of Mechanical Engineers (ASME) or the International Organization for Standardization (ISO) exhibit a level of quality and safety that buyers can trust. Industry leaders often set benchmarks in valve technology, innovating in areas such as flow efficiency, sealing technology, and ergonomic design to enhance user experience while adhering to these authoritative standards. Trustworthiness in the context of angle needle valves is established through a track record of safety and efficiency. Manufacturers often conduct rigorous testing procedures to ensure each valve meets the required specifications without failure. Customer testimonials and long-term warranties offer additional assurance of a product's reliability. Trustworthy brands also engage in transparent communication with customers, providing detailed usage guidelines and after-sales support to foster confidence in their products. In conclusion, the value of angle needle valves lies in their ability to deliver precise fluid control across a myriad of settings. Users who rely on their performance appreciate the exactitude and reliability that these components bring to their operations. The quality assurance and adherence to industry standards reinforce their position as a trusted tool in both routine and specialized situations. Whether in high-pressure gas systems, lab environments, or fluid power applications, angle needle valves provide the level of control necessary to achieve optimal outcomes.

Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025