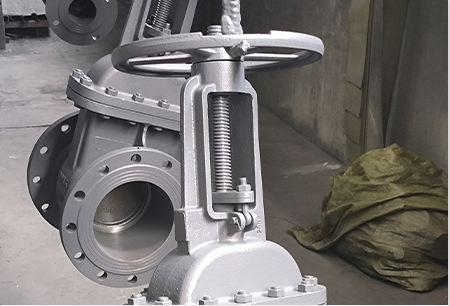

industrial flanges manufacturers

Understanding Industrial Flanges Manufacturers Key Players in the Supply Chain

In the world of industrial manufacturing, flanges play a crucial role in piping systems and various mechanical applications. These critical components serve as a means of connection, providing a secure junction between pipes, valves, and other equipment. As industries continue to evolve, the demand for high-quality, precision-engineered flanges has surged, giving rise to a diverse landscape of industrial flanges manufacturers. This article delves into the importance of these manufacturers, the types of flanges they produce, and the factors to consider when selecting a supplier.

The Role of Flanges in Industry

Flanges are mechanical components that facilitate the joining of two equipment pieces, ensuring a leak-proof and firm connection. They are widely used in various sectors, including oil and gas, chemical processing, water treatment, and construction. Flanges come in various designs, materials, and sizes, catering to the specific demands of different applications. Their durability, resistance to pressure, and adaptability to different settings make them indispensable.

Types of Flanges

Industrial flanges are categorized into several types, each serving unique purposes

1. Weld Neck Flanges Often used in high-pressure applications, these flanges are welded to the pipe, providing a strong and durable connection. They are ideal for supporting the weight of heavy piping systems.

2. Slip-On Flanges Designed to slide over the pipe, these flanges are easier to install and are commonly used in lower-pressure applications.

3. Blind Flanges These flanges are used to seal the end of a piping system, preventing flow or access to the interior. They are vital for maintenance and safety purposes.

4. Socket Weld Flanges These are similar to weld neck flanges but are designed for smaller diameter pipes. They are often used in high-pressure systems.

5. Lap Joint Flanges These flanges are designed to work with a corresponding stub end, allowing for easy alignment and disassembly.

industrial flanges manufacturers

The Importance of Choosing the Right Manufacturer

With numerous industrial flanges manufacturers vying for market share, it can be daunting for businesses to select the right supplier. Here are some factors to consider when evaluating potential manufacturers

1. Quality Standards Look for manufacturers who adhere to international quality standards, such as ASTM, ASME, or ISO certifications. High-quality flanges are essential to preventing leaks and ensuring the safety and efficiency of piping systems.

2. Experience and Reputation Established manufacturers often have a proven track record in the industry. Researching their history, client testimonials, and case studies can provide insight into their reliability and expertise.

3. Customization Options Depending on the specific application, you may need custom flanges. A flexible manufacturer who can accommodate unique designs and specifications is invaluable.

4. Material Selection Flanges can be made from various materials, including stainless steel, carbon steel, and alloy materials. Ensure that the manufacturer has access to the right materials for your specific needs.

5. Lead Time and Delivery Consider the manufacturer's lead time for production and their ability to meet delivery schedules. Timely delivery is critical in maintaining project timelines and avoiding costly delays.

6. Customer Support A manufacturer that provides robust customer support can make a significant difference. Whether it’s technical assistance or responding to inquiries, excellent customer service is essential for long-term partnerships.

Conclusion

Industrial flanges manufacturers are key players in the manufacturing and supply chain landscape. As industries continue to grow, the demand for high-quality flanges will persist, necessitating careful consideration when choosing a manufacturer. By understanding the types of flanges available and the factors influencing supplier selection, businesses can ensure they forge strong partnerships with manufacturers equipped to meet their needs effectively.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025