Gearr . 13, 2025 21:52

Back to list

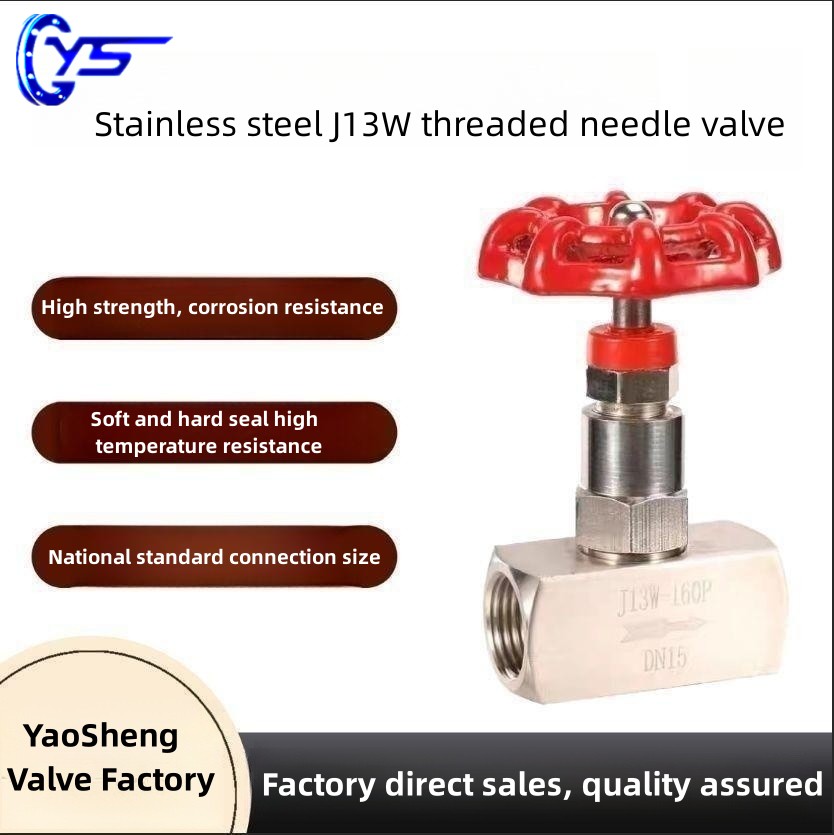

6mm needle valve

The 6mm needle valve stands out as a key component in various industries, known for its precise control over fluid flow. This valve is particularly essential when dealing with applications that demand exact flow regulation, making it indispensable for engineers and technicians who prioritize accuracy and reliability in their operations.

Authoritativeness in Fluid Control Applications The authoritative aspect of using a 6mm needle valve is evident in its applicability across several demanding sectors. Industry leaders and standard bodies often include needle valves in protocols and design standards due to their proven effectiveness. In the oil and gas industry, for example, these valves are vital for managing the flow of hydrocarbons through pipelines, ensuring safety and efficiency. The meticulous construction and testing processes that these valves undergo before market introduction speak volumes about their role as a trusted component in fluid control applications. Trustworthiness and Reliable Performance Trustworthiness in equipment translates to confidence in operations, and the 6mm needle valve is no exception. Users continually rely on these valves for operational consistency and safety, knowing that the precision-engineered components can withstand rigorous use. The accuracy of a 6mm needle valve often minimizes the risk of leaks and failures, a critical factor when dealing with hazardous or expensive materials. Furthermore, their maintenance-friendly nature, characterized by easy disassembly and cleaning, ensures long-term reliability and cost-effectiveness, a stark advantage in environments where downtime equates to financial loss. In conclusion, the 6mm needle valve embodies the quintessential balance between precision and durability, making it a cornerstone in industries where exactness cannot be compromised. From its detailed design to its consistent performance, this valve consistently meets the high expectations of professionals who seek trusted and authoritative equipment solutions. Whether implementing new systems or upgrading existing ones, choosing a 6mm needle valve ensures that operations remain smooth, safe, and efficient, a testament to its enduring value in the realm of fluid control.

Authoritativeness in Fluid Control Applications The authoritative aspect of using a 6mm needle valve is evident in its applicability across several demanding sectors. Industry leaders and standard bodies often include needle valves in protocols and design standards due to their proven effectiveness. In the oil and gas industry, for example, these valves are vital for managing the flow of hydrocarbons through pipelines, ensuring safety and efficiency. The meticulous construction and testing processes that these valves undergo before market introduction speak volumes about their role as a trusted component in fluid control applications. Trustworthiness and Reliable Performance Trustworthiness in equipment translates to confidence in operations, and the 6mm needle valve is no exception. Users continually rely on these valves for operational consistency and safety, knowing that the precision-engineered components can withstand rigorous use. The accuracy of a 6mm needle valve often minimizes the risk of leaks and failures, a critical factor when dealing with hazardous or expensive materials. Furthermore, their maintenance-friendly nature, characterized by easy disassembly and cleaning, ensures long-term reliability and cost-effectiveness, a stark advantage in environments where downtime equates to financial loss. In conclusion, the 6mm needle valve embodies the quintessential balance between precision and durability, making it a cornerstone in industries where exactness cannot be compromised. From its detailed design to its consistent performance, this valve consistently meets the high expectations of professionals who seek trusted and authoritative equipment solutions. Whether implementing new systems or upgrading existing ones, choosing a 6mm needle valve ensures that operations remain smooth, safe, and efficient, a testament to its enduring value in the realm of fluid control.

Next:

Latest news

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025