flap valve manufacturers

The Role of Flap Valve Manufacturers in Industrial Applications

Flap valves, also known as check valves or non-return valves, play a pivotal role in various industrial applications by preventing backflow in piping systems. These essential components are designed to allow fluid or gas to flow in one direction while preventing reverse flow, thereby protecting equipment and maintaining system efficiency. The importance of flap valve manufacturers cannot be overstated, as they contribute significantly to the reliability and performance of many industries, including oil and gas, water treatment, and chemical processing.

Understanding Flap Valves

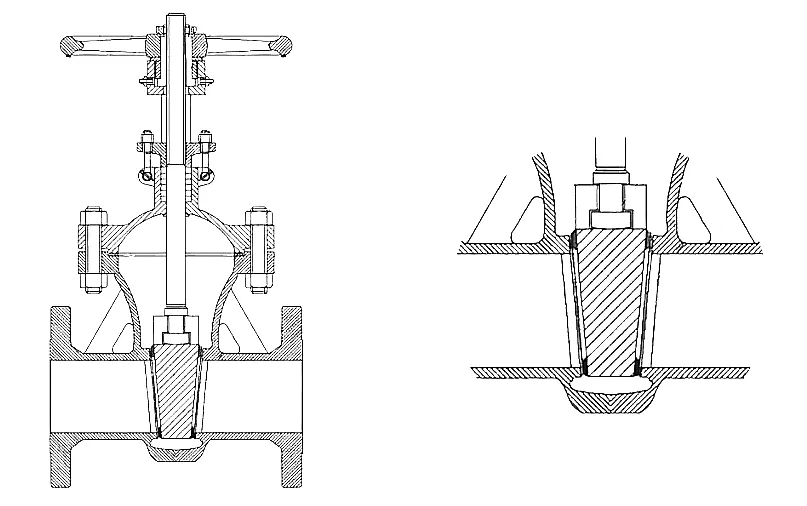

Flap valves are typically made from a variety of materials, including metal, plastic, and rubber, depending on the application and the type of fluid being conveyed. The design is relatively simple, often comprising a hinged flap that opens when there is forward flow and closes to create a seal when the flow reverses. This straightforward mechanism allows flap valves to operate automatically, which minimizes the need for maintenance and reduces the risk of operator error.

The versatility of flap valves makes them suitable for numerous applications. In water treatment facilities, for example, flap valves are crucial for controlling flow and preventing contamination of clean water supplies. In the oil and gas industry, these valves prevent backflow that could compromise safety and operational integrity. Additionally, in wastewater management, flap valves help in maintaining proper drainage and preventing backflow into sewer systems.

Choosing the Right Manufacturer

When it comes to selecting a flap valve manufacturer, various factors must be considered to ensure the best fit for specific industrial needs. Below are some key considerations

1. Quality and Standards A reputable flap valve manufacturer should adhere to industry standards and certifications. Look for manufacturers that have ISO certifications or comply with ANSI and ASTM standards. High-quality materials and manufacturing processes are essential for ensuring the longevity and reliability of flap valves.

flap valve manufacturers

2. Customization Options Every application has unique requirements. A good manufacturer will offer customization options to meet specific operational needs, such as size, material, and design. Custom-engineered flap valves can optimize performance in a given system and provide enhanced efficiency.

3. Experience and Expertise The experience level of the manufacturer is crucial. Manufacturers with a proven track record in the industry are likely to have better insights into the challenges faced in various applications. Their expertise can guide customers in choosing the right flap valves and even assist in troubleshooting any issues.

4. Technical Support and Service After-sales service and technical support are vital components of a good manufacturing partnership. A reliable manufacturer should offer comprehensive support, including installation guidance, maintenance tips, and access to spare parts. This ongoing support can prolong the lifespan of flap valves and ensure optimal performance.

Innovations in Flap Valve Manufacturing

The manufacturing landscape for flap valves is continually evolving with technological advancements. Modern manufacturers are integrating innovative materials and designs that enhance the performance and durability of flap valves. For instance, the use of advanced composites and elastomers can result in light-weight yet durable valves that withstand harsh operating conditions.

Additionally, automation and smart technologies are making their way into flap valve systems. Internet of Things (IoT) integration allows real-time monitoring of valve performance, enabling predictive maintenance and reducing downtime. Manufacturers who embrace these innovations can offer higher-quality products that increase operational efficiency and reduce costs for their customers.

Conclusion

Flap valve manufacturers play an integral role in ensuring the functionality and reliability of many industrial processes. By providing high-quality, customized solutions, they safeguard systems against backflow and maintain efficiency in fluid and gas handling applications. As industries evolve and new technologies emerge, the role of flap valve manufacturers will continue to be critical in promoting safety, efficiency, and sustainability in various operations. Whether you are in the oil and gas sector, water treatment facilities, or chemical processing, partnering with the right flap valve manufacturer can make a significant difference for your operational needs.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025