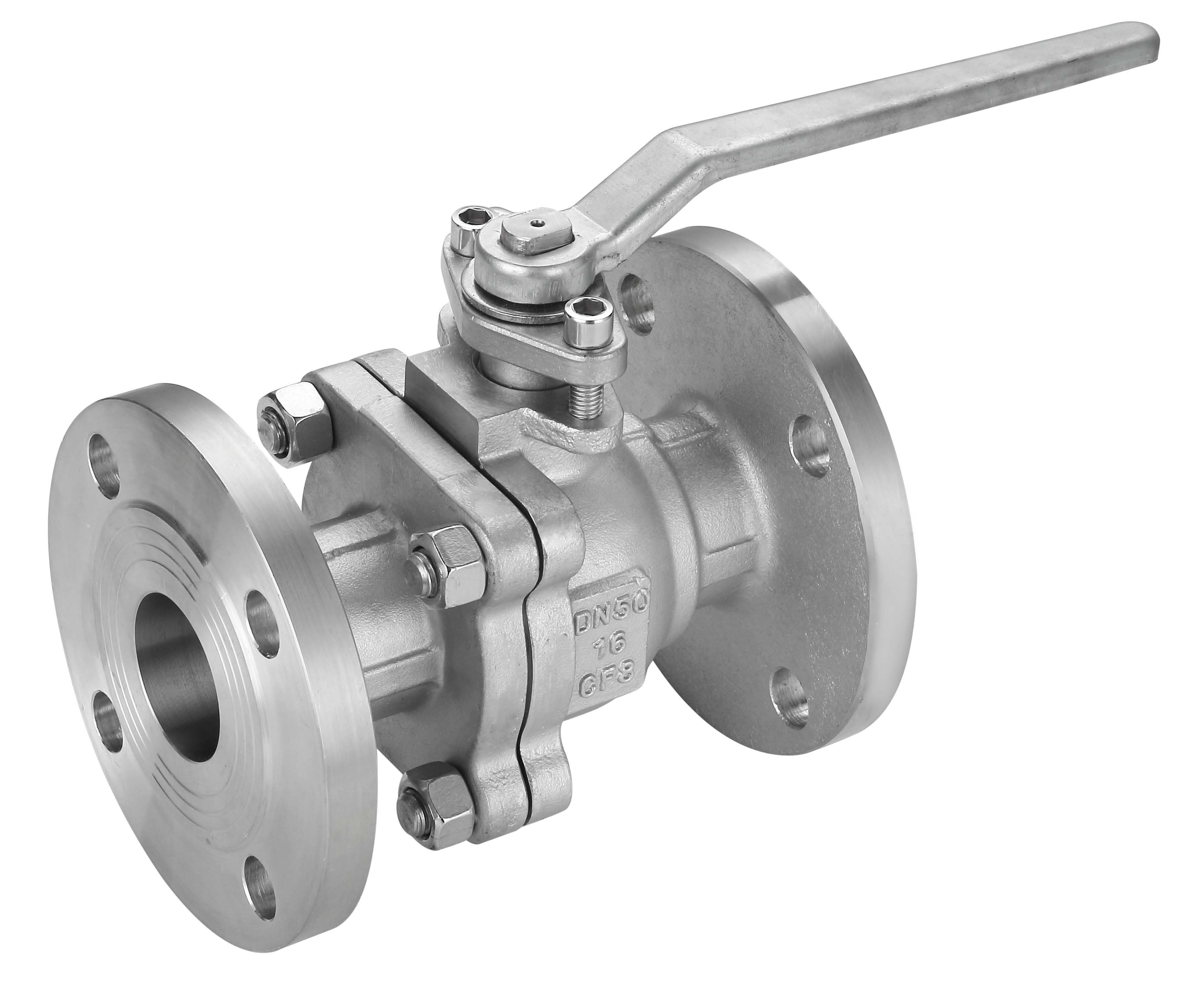

1 1 2 ball valve stainless

Understanding 1% 201% 202% Ball Valve Stainless Steel A Comprehensive Overview

In the world of industrial valves, the ball valve stands out for its reliability, durability, and efficiency. Often utilized in applications requiring a tight seal and quick operation, the stainless steel ball valve, particularly those made from specific stainless steel grades such as 201 and 202, has become a preferred choice in various industries. This article delves into these materials, their benefits, and their applications, providing a comprehensive understanding of the 1% 201% 202% ball valve stainless steel.

What are Ball Valves?

Ball valves are quarter-turn valves that use a spherical disc, known as a ball, to control the flow of fluids. When the valve handle is turned to open the valve, the ball rotates to allow fluid to pass through; when it’s turned in the opposite direction, the flow is stopped as the ball blocks the passage. This simple yet effective mechanism provides swift functionality, making ball valves ideal for on/off control applications.

Stainless Steel The Material of Choice

Stainless steel is an alloy known for its strength, resistance to corrosion, and durability. It typically consists of steel mixed with chromium and, in some cases, nickel. The inclusion of these elements enhances the material's properties, making it ideal for harsh environments.

Specifically, the grades 201 and 202 stainless steel have gained attention in the manufacturing of ball valves. While both grades offer impressive properties, they possess distinct characteristics

- 201 Stainless Steel This grade is often regarded as a cost-effective alternative to 304 stainless steel. It is composed of about 16-18% chromium and 3-5% nickel, alongside higher levels of manganese. 201 stainless steel is known for its good tensile strength and formability. However, it is more prone to corrosion when exposed to harsh chemicals or environments, making it more suitable for mild applications.

- 202 Stainless Steel A variant of 201, 202 stainless steel includes a similar structure but has slightly higher nickel content, typically around 4-6%. This makes it somewhat more resistant to corrosion and better suited for applications where enhanced durability is required. Furthermore, 202 stainless steel can provide excellent structural support in environments subject to significant wear and tear.

Benefits of Using 1% 201% 202% Ball Valves

1. Cost-Effectiveness Comparing to higher grades like 304 or 316, the cost of materials for 201 and 202 stainless steel ball valves is generally lower. This is particularly advantageous for projects with strict budgetary constraints.

1 1 2 ball valve stainless

2. Durability Stainless steel ball valves are highly durable and can withstand high-pressure scenarios. The intrinsic strength of 201 and 202 stainless steel ensures that they can maintain their integrity over time, reducing the need for frequent replacements.

3. Corrosion Resistance While not as resistant as higher-grade stainless steels, both 201 and 202 provide adequate resistance to rust and corrosion for many general applications, especially in less aggressive environments.

4. Efficient Operation The quarter-turn design of ball valves allows for quick opening and closing operations. They can be easily manipulated by hand or via automation, making them versatile in a variety of settings.

5. Low Maintenance Ball valves require minimal maintenance. Their simple design means fewer components are prone to failure, leading to lower operational costs over time.

Applications of 1% 201% 202% Ball Valves

These stainless steel ball valves are used in a myriad of applications

- Water Supply Systems They are commonly employed in irrigation, water treatment, and distribution systems, where reliable operation is critical.

- Chemical Processing Although 201 stainless steel has limited chemical resistance, both grades can be utilized in less demanding chemical environments.

- HVAC Systems In heating, ventilation, and air conditioning systems, these valves manage the flow of water and air with efficiency.

Conclusion

In summary, 1% 201% 202% ball valve stainless steel presents an effective solution for various industries. Their combination of cost-effectiveness, durability, and operational efficiency makes them an attractive choice for many applications. By understanding these materials and their characteristics, engineers and procurement professionals can make informed decisions when specifying valves for their projects. Whether in water systems or HVAC applications, the use of stainless steel ball valves exemplifies the balance between performance and cost in industrial settings.

-

3-types-of-check-valves-maintenance-tipsNewsAug.23,2025

-

ball-valves-types-with-trunnion-mounted-designNewsAug.23,2025

-

butterfly-valve-company-production-capabilitiesNewsAug.23,2025

-

fisher-globe-valve-technical-specificationsNewsAug.23,2025

-

types-of-gaskets-for-flanges-selection-guideNewsAug.23,2025

-

wedge-gate-valve-suppliers-quality-standardsNewsAug.23,2025

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025