Socket Weld Needle Valve Suppliers and Their Key Features for Industrial Applications

Socket Weld Needle Valve Manufacturers An Overview

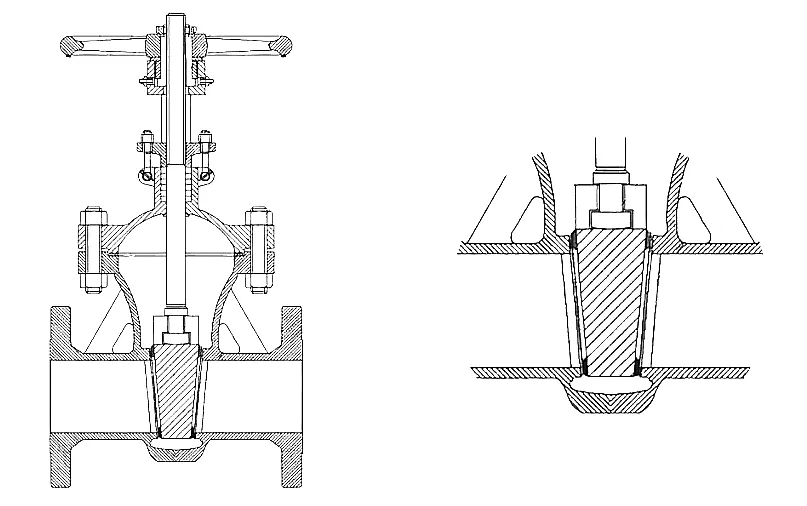

Socket weld needle valves are essential components in fluid control systems, particularly in industries such as oil and gas, petrochemical, and chemical processing. These valves are designed to regulate the flow of liquids and gases with high precision, ensuring optimal operational efficiency. As the demand for such valves continues to grow, many manufacturers have emerged, offering a variety of products tailored to meet specific industry needs.

When searching for reputable socket weld needle valve manufacturers, it's vital to consider a few key factors. First, the material composition of the valves plays a fundamental role in their durability and suitability for various applications. Most manufacturers provide valves made from stainless steel, carbon steel, and brass, each suited for different environmental conditions and media. Stainless steel, for example, is preferred in corrosive environments due to its resistance to oxidation and corrosion.

Another significant aspect to consider is the manufacturer’s certifications and compliance with industry standards. Leading manufacturers often comply with high standards such as ASTM, ASME, and API, ensuring that their products meet rigorous quality requirements. This compliance not only enhances product reliability but also instills confidence in customers regarding safety and performance.

socket weld needle valve manufacturers

Moreover, the design and features of socket weld needle valves can vary among manufacturers. Advanced designs may include features like low torque operation, a robust seating mechanism to minimize leakages, and ergonomic handles for ease of use. It’s essential for buyers to assess these features and determine which options best match their specific operational requirements.

Cost is another critical factor when evaluating socket weld needle valve manufacturers. While it might be tempting to opt for the cheapest option, it’s important to balance cost with quality. Investing in high-quality valves may result in lower maintenance costs and improved longevity, ultimately presenting a better value over time.

Additionally, customer support and service reliability can greatly influence the relationship between manufacturers and their clients. Leading manufacturers often provide comprehensive after-sales support, including assistance with installation and maintenance, which can be invaluable for companies looking to ensure seamless operation of their fluid control systems.

In conclusion, selecting the right socket weld needle valve manufacturer involves careful consideration of material quality, compliance with industry standards, design features, cost, and customer support. As industries continue to evolve, reliable and efficient needle valves will remain integral to fluid management systems, making it crucial to partner with manufacturers who prioritize quality and innovation.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025