Half-Inch ProPress Ball Valve Manufacturers and Their Quality Assurance Standards in Plumbing Industry

Half Inch ProPress Ball Valve Factories A Comprehensive Overview

In the world of plumbing and industrial piping, the importance of robust, reliable components cannot be overstated. One such component that has gained immense popularity in recent years is the half-inch ProPress ball valve. These valves are not only critical for controlling the flow of liquids and gases but also for ensuring system efficiency and integrity. This article explores the significance of half-inch ProPress ball valve factories and what makes them a vital part of modern infrastructure.

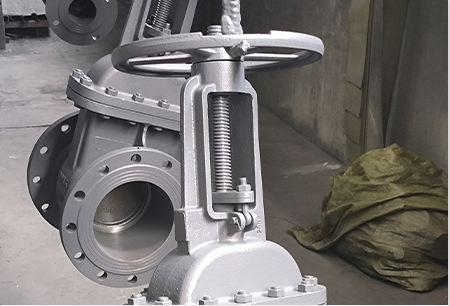

Understanding ProPress Ball Valves

ProPress ball valves are designed for quick and easy installation in piping systems, particularly in residential and commercial applications. They feature a unique pressing technology that allows them to be installed without the need for welding or soldering, dramatically reducing installation time and labor costs. The half-inch variant is particularly popular due to its versatility and compatibility with a wide range of applications, including heating, cooling, and potable water delivery.

Role of Factories in Production

The role of factories that specialize in producing half-inch ProPress ball valves is crucial to ensuring a consistent supply of high-quality products. These factories employ advanced manufacturing techniques and state-of-the-art machinery to meet strict industry standards. Attention to detail in manufacturing processes is vital, as the performance of these valves can significantly impact the overall functionality and safety of plumbing systems.

Quality Assurance and Standards

To ensure the reliability of half-inch ProPress ball valves, factories must adhere to stringent quality assurance protocols. This includes regular testing of materials, pressure tests, and adherence to relevant safety and performance standards, such as those set by the International Organization for Standardization (ISO) and the American Society of Mechanical Engineers (ASME). By meeting these standards, manufacturers can guarantee that their products will withstand the rigors of everyday use and last for years without failure.

half inch propress ball valve factories

Sustainability Practices

With the increasing emphasis on sustainability in manufacturing, many half-inch ProPress ball valve factories are implementing eco-friendly practices. This includes using recyclable materials in production, reducing waste, and minimizing energy consumption during manufacturing processes. By focusing on sustainable practices, these factories not only contribute to environmental conservation but also appeal to a growing market of environmentally conscious consumers.

Market Demand and Trends

The demand for half-inch ProPress ball valves is on the rise, driven by various factors including the growth of the construction sector, increasing investments in infrastructure, and the push for efficient and reliable plumbing solutions. As more buildings adopt modern plumbing systems that prioritize efficiency and ease of maintenance, the need for high-quality ball valves has never been greater.

Moreover, innovations in valve design and functionality are leading to the development of more advanced models, further enhancing their appeal. Factories that stay ahead of these trends by investing in research and development are better positioned to meet market needs and secure their place in the industry.

Conclusion

In conclusion, half-inch ProPress ball valve factories play an indispensable role in the plumbing and industrial piping sectors. By prioritizing quality, sustainability, and innovation, these manufacturers not only contribute to the reliability and efficiency of water and gas systems but also adapt to market trends and consumer needs. As the industry continues to evolve, the significance of these valves and the factories that produce them will undoubtedly remain pivotal to the infrastructure that supports our daily lives. Whether in residential homes or large-scale industrial applications, half-inch ProPress ball valves are essential components that ensure the smooth operation of vital systems.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025