Top Manufacturers of Butterfly Check Valves for Reliable Fluid Control Solutions

Butterfly Check Valve Manufacturer An Overview

In the world of fluid management, check valves play a crucial role in ensuring the smooth and safe operation of various systems. Among the various types of check valves, the butterfly check valve is particularly noteworthy for its unique design and functionality. This article aims to explore the role of butterfly check valve manufacturers in the industry, shedding light on their products, advantages, and the factors to consider when choosing a manufacturer.

Understanding Butterfly Check Valves

Before delving into the manufacturers, it’s essential to understand what a butterfly check valve is. Unlike traditional check valves that utilize a ball or swing mechanism to prevent backflow, butterfly check valves use a disc positioned in the center of the valve body. When fluid flows in the forward direction, the disc remains open, allowing the liquid to pass through. If there is any reverse flow, the disc rotates and seals against the valve body, preventing backflow. This simple yet effective design allows for lower pressure drops and faster response times, making butterfly check valves a preferred choice in many applications.

The Role of Manufacturers

Manufacturers of butterfly check valves are integral to maintaining the supply chain for industries that rely on these essential components. They are responsible for designing, producing, and distributing valves that meet specific industry standards. These manufacturers invest in research and development to improve the performance, durability, and efficiency of their products. They also adhere to strict quality control measures to ensure that each valve can withstand varying pressures and temperatures.

Key Advantages of Butterfly Check Valves

1. Compact Design One of the primary advantages of butterfly check valves is their compact size. This allows for easier installation in tight spaces compared to other types of check valves. Manufacturers are capitalizing on this feature to cater to industries where space is a premium.

2. Lightweight Materials Butterfly check valves are typically made from materials like plastic, aluminum, or stainless steel, which are both lightweight and corrosion-resistant. This characteristic allows for easier handling and reduces transportation costs.

3. Minimal Pressure Drop Due to their design, butterfly check valves generally have lower pressure drops compared to traditional check valves. This leads to increased efficiency in fluid systems.

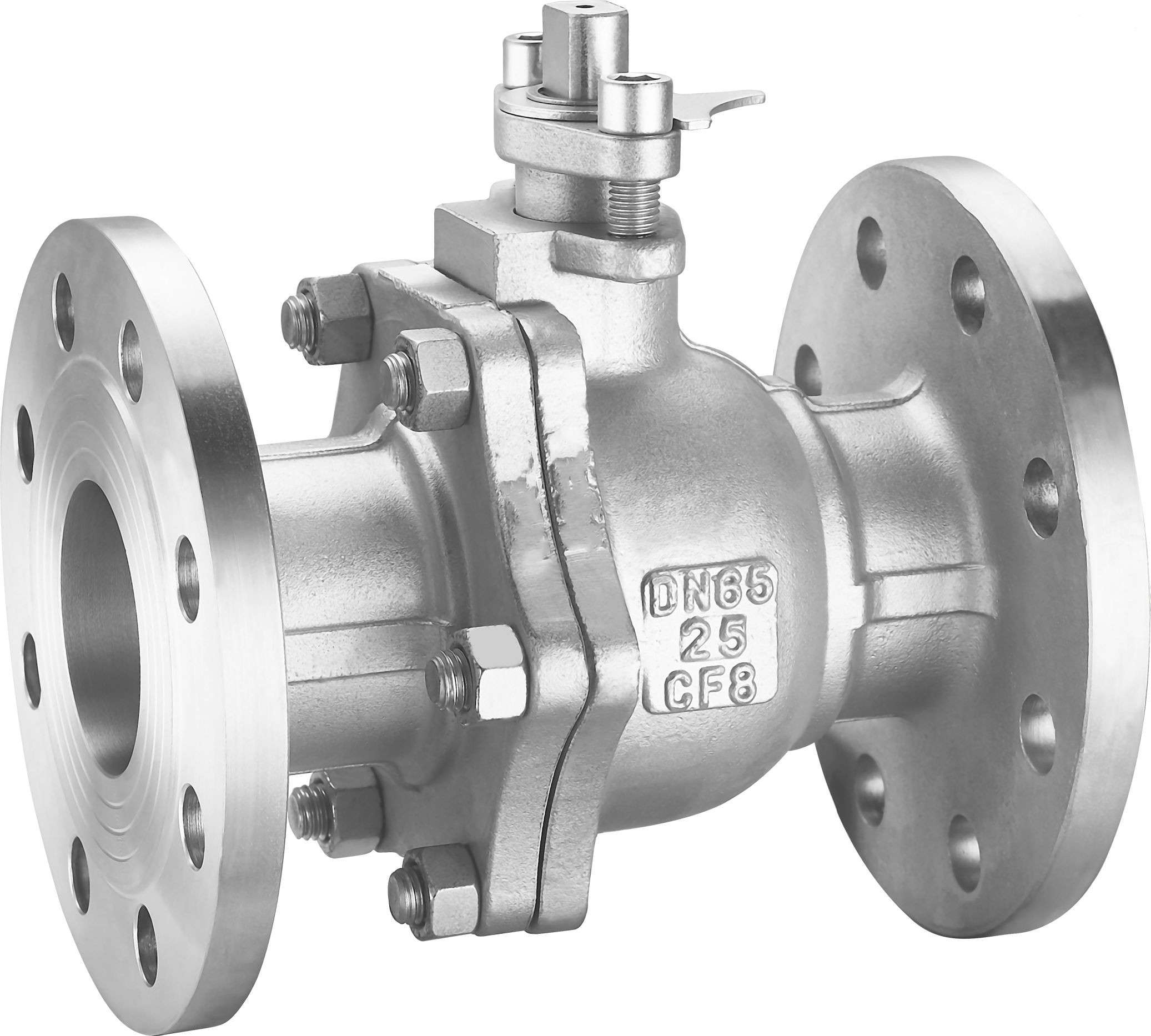

butterfly check valve manufacturer

4. Versatility These valves are suitable for various applications, including water treatment, HVAC systems, and chemical processing. Manufacturers often provide a range of options to cater to different industry needs.

Factors to Consider When Choosing a Manufacturer

When selecting a butterfly check valve manufacturer, several factors should be considered

- Quality Assurance Ensure the manufacturer follows industry standards and certifications, such as ISO 9001. This guarantees that their products meet global quality benchmarks.

- Experience and Reputation Opt for manufacturers with a proven track record in the industry. Established manufacturers often have the experience to develop high-quality, reliable products.

- Customization Options Depending on your specific needs, you may require customized solutions. Look for manufacturers that offer customization options to meet your unique operational requirements.

- Customer Support Comprehensive customer service is vital for addressing any issues that may arise post-purchase. A good manufacturer should provide technical support and a clear warranty policy.

- Price and Value While price is a critical consideration, it is essential to weigh it against the overall value and quality of the product. Cheaper options may save upfront cash but could lead to higher maintenance costs over time.

Conclusion

Butterfly check valves are indispensable components in various fluid management systems. As demand for efficient and reliable valves continues to grow, manufacturers play a crucial role in the innovation and supply of these essential products. By understanding what to look for in a butterfly check valve manufacturer, industries can ensure they are equipped with high-quality valves that enhance their operational efficiency and safety.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025