Jun . 12, 2024 23:46

Back to list

Valve fittings manufacturing plants

Valves and Pipe Fittings The Heart of Modern Industry

In the bustling realm of modern industry, a wide array of components converge to ensure seamless operation. Among these, valves and pipe fittings stand out as essential parts, serving as the lifeblood of process machinery.

Valves are intricate devices that regulate the flow of fluids and gases within pipelines and systems. Their versatile designs allow for precise control over temperature, pressure, and flow rates. The selection of a valve hinges on factors such as the type of fluid being handled, the operating conditions, and the desired level of control。Common types of valves include ball valves, gate valves, diaphragm valves, and butterfly valves, each with their unique attributes ideal for specific applications in industries like oil and gas, water treatment, pharmaceuticals, and power generation.

Valve manufacturers face numerous challenges in producing reliable products that meet the exacting specifications of end-users. Constant research and development enable these companies to innovate and enhance valve performance, durability, and efficiency Constant research and development enable these companies to innovate and enhance valve performance, durability, and efficiency Constant research and development enable these companies to innovate and enhance valve performance, durability, and efficiency Constant research and development enable these companies to innovate and enhance valve performance, durability, and efficiency

Constant research and development enable these companies to innovate and enhance valve performance, durability, and efficiency Constant research and development enable these companies to innovate and enhance valve performance, durability, and efficiency valves pipe fittings factories. Additionally, advancements in materials science and manufacturing technologies have led to the creation of high-performance specialty valves that can withstand severe conditions such as extreme temperatures, corrosive environments, and high pressures。

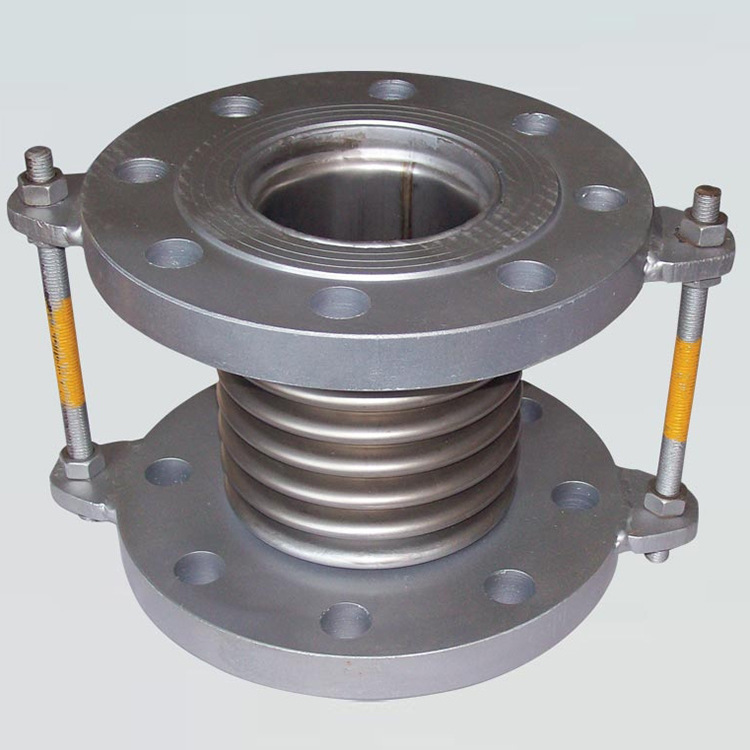

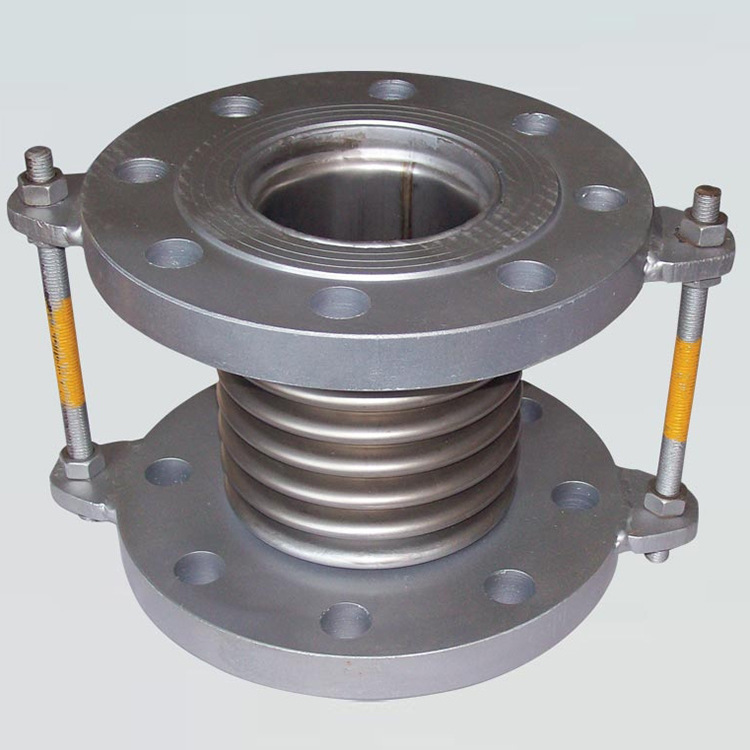

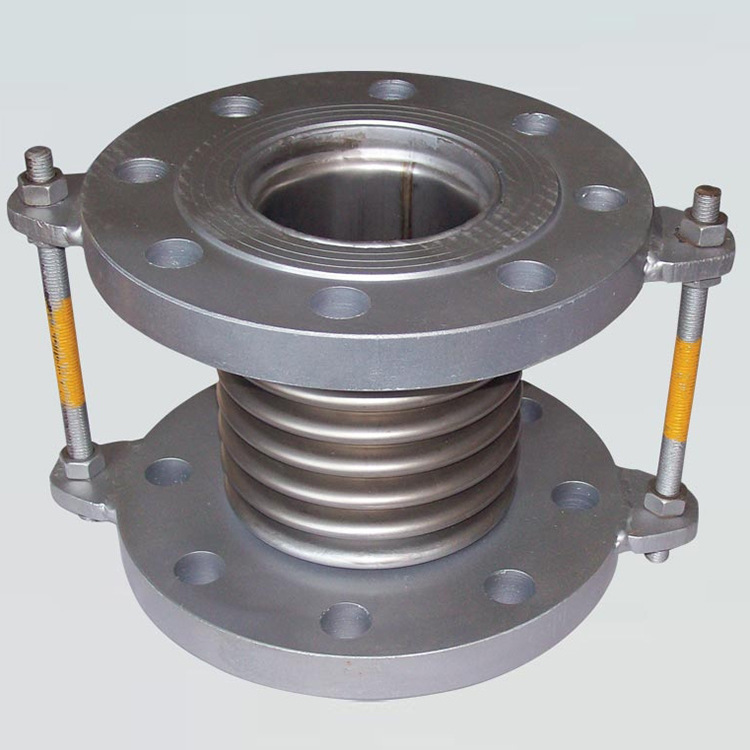

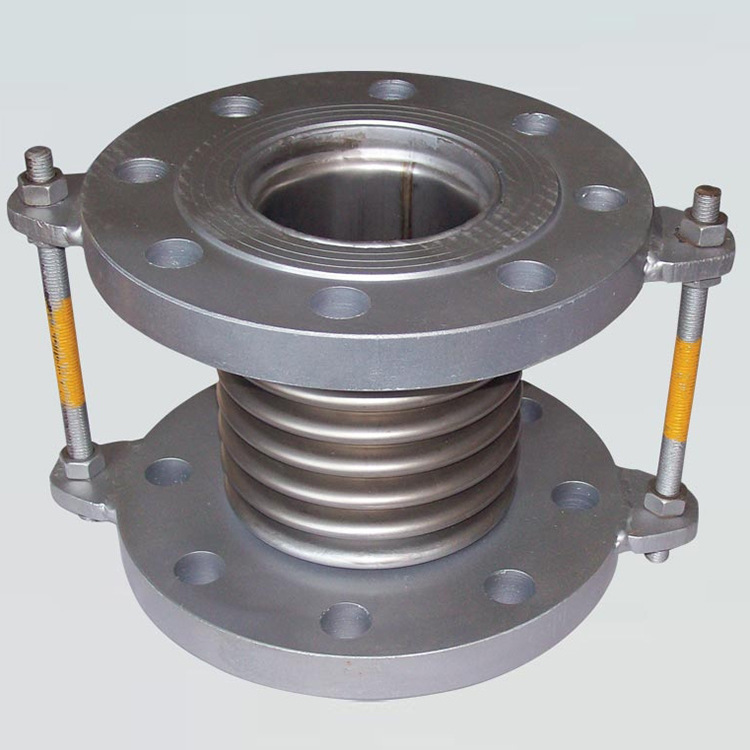

Pipe fittings, another vital component, serve as connectors between pipes, ensuring the integrity of fluid transport systems. These components come in myriad shapes, sizes, and materials to suit different applications. Threaded fittings, flanges, adapters, and reducers are some common types, each designed to facilitate a secure connection and maintain optimal fluid flow.

Manufacturers of pipe fittings must adhere to strict quality standards to ensure the integrity and safety of pipelines. They employ sophisticated equipment and use advanced materials such as stainless steel, carbon steel, and copper to produce fittings that can withstand various conditions and last for extended periods。

Together, valves and pipe fittings form the backbone of modern industrial processes, supporting the smooth functioning of a wide range of operations。Their performance directly impacts the efficiency, safety, and sustainability of industrial systems. As such, manufacturers of these components must continue to innovate and improve to meet the ever-evolving needs of industries worldwide。

valves pipe fittings factories. Additionally, advancements in materials science and manufacturing technologies have led to the creation of high-performance specialty valves that can withstand severe conditions such as extreme temperatures, corrosive environments, and high pressures。

Pipe fittings, another vital component, serve as connectors between pipes, ensuring the integrity of fluid transport systems. These components come in myriad shapes, sizes, and materials to suit different applications. Threaded fittings, flanges, adapters, and reducers are some common types, each designed to facilitate a secure connection and maintain optimal fluid flow.

Manufacturers of pipe fittings must adhere to strict quality standards to ensure the integrity and safety of pipelines. They employ sophisticated equipment and use advanced materials such as stainless steel, carbon steel, and copper to produce fittings that can withstand various conditions and last for extended periods。

Together, valves and pipe fittings form the backbone of modern industrial processes, supporting the smooth functioning of a wide range of operations。Their performance directly impacts the efficiency, safety, and sustainability of industrial systems. As such, manufacturers of these components must continue to innovate and improve to meet the ever-evolving needs of industries worldwide。

Constant research and development enable these companies to innovate and enhance valve performance, durability, and efficiency Constant research and development enable these companies to innovate and enhance valve performance, durability, and efficiency

Constant research and development enable these companies to innovate and enhance valve performance, durability, and efficiency Constant research and development enable these companies to innovate and enhance valve performance, durability, and efficiency valves pipe fittings factories. Additionally, advancements in materials science and manufacturing technologies have led to the creation of high-performance specialty valves that can withstand severe conditions such as extreme temperatures, corrosive environments, and high pressures。

Pipe fittings, another vital component, serve as connectors between pipes, ensuring the integrity of fluid transport systems. These components come in myriad shapes, sizes, and materials to suit different applications. Threaded fittings, flanges, adapters, and reducers are some common types, each designed to facilitate a secure connection and maintain optimal fluid flow.

Manufacturers of pipe fittings must adhere to strict quality standards to ensure the integrity and safety of pipelines. They employ sophisticated equipment and use advanced materials such as stainless steel, carbon steel, and copper to produce fittings that can withstand various conditions and last for extended periods。

Together, valves and pipe fittings form the backbone of modern industrial processes, supporting the smooth functioning of a wide range of operations。Their performance directly impacts the efficiency, safety, and sustainability of industrial systems. As such, manufacturers of these components must continue to innovate and improve to meet the ever-evolving needs of industries worldwide。

valves pipe fittings factories. Additionally, advancements in materials science and manufacturing technologies have led to the creation of high-performance specialty valves that can withstand severe conditions such as extreme temperatures, corrosive environments, and high pressures。

Pipe fittings, another vital component, serve as connectors between pipes, ensuring the integrity of fluid transport systems. These components come in myriad shapes, sizes, and materials to suit different applications. Threaded fittings, flanges, adapters, and reducers are some common types, each designed to facilitate a secure connection and maintain optimal fluid flow.

Manufacturers of pipe fittings must adhere to strict quality standards to ensure the integrity and safety of pipelines. They employ sophisticated equipment and use advanced materials such as stainless steel, carbon steel, and copper to produce fittings that can withstand various conditions and last for extended periods。

Together, valves and pipe fittings form the backbone of modern industrial processes, supporting the smooth functioning of a wide range of operations。Their performance directly impacts the efficiency, safety, and sustainability of industrial systems. As such, manufacturers of these components must continue to innovate and improve to meet the ever-evolving needs of industries worldwide。 Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025