יונ . 27, 2024 08:16

Back to list

Top Pipe Socket Weld Fittings Manufacturers Exploring Leading Factories

Understanding Pipe Socket Weld Fittings A Glimpse into Global Manufacturing Factories

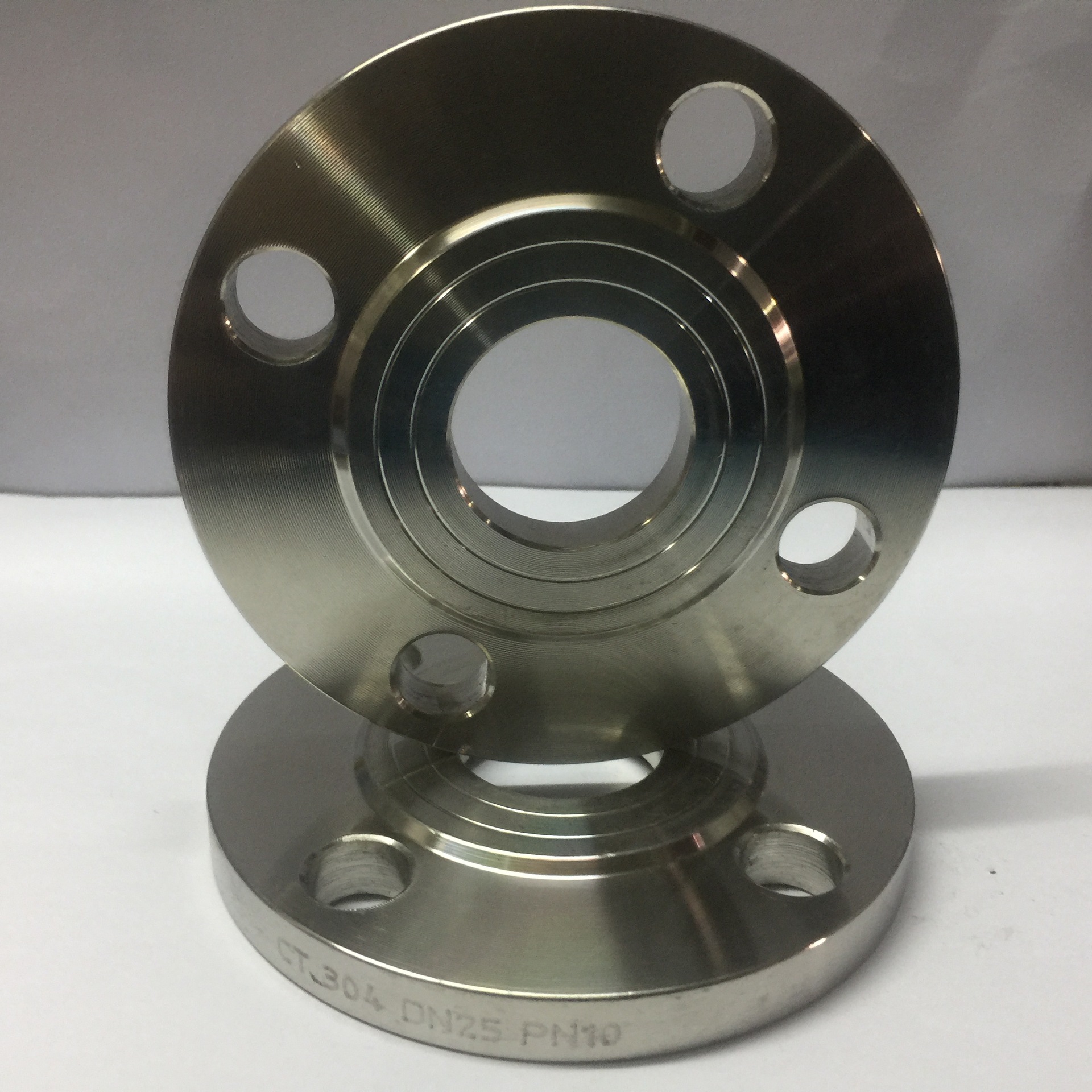

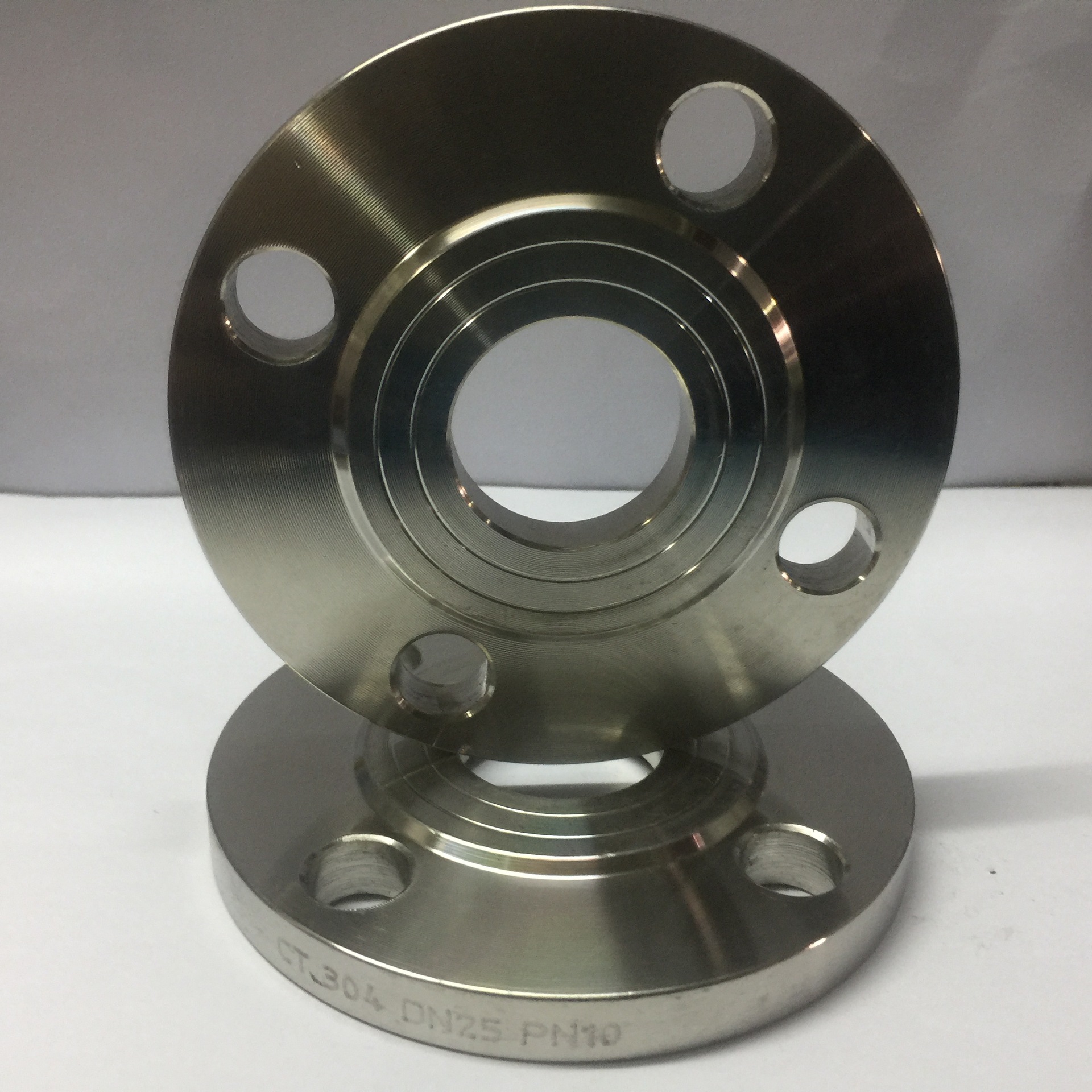

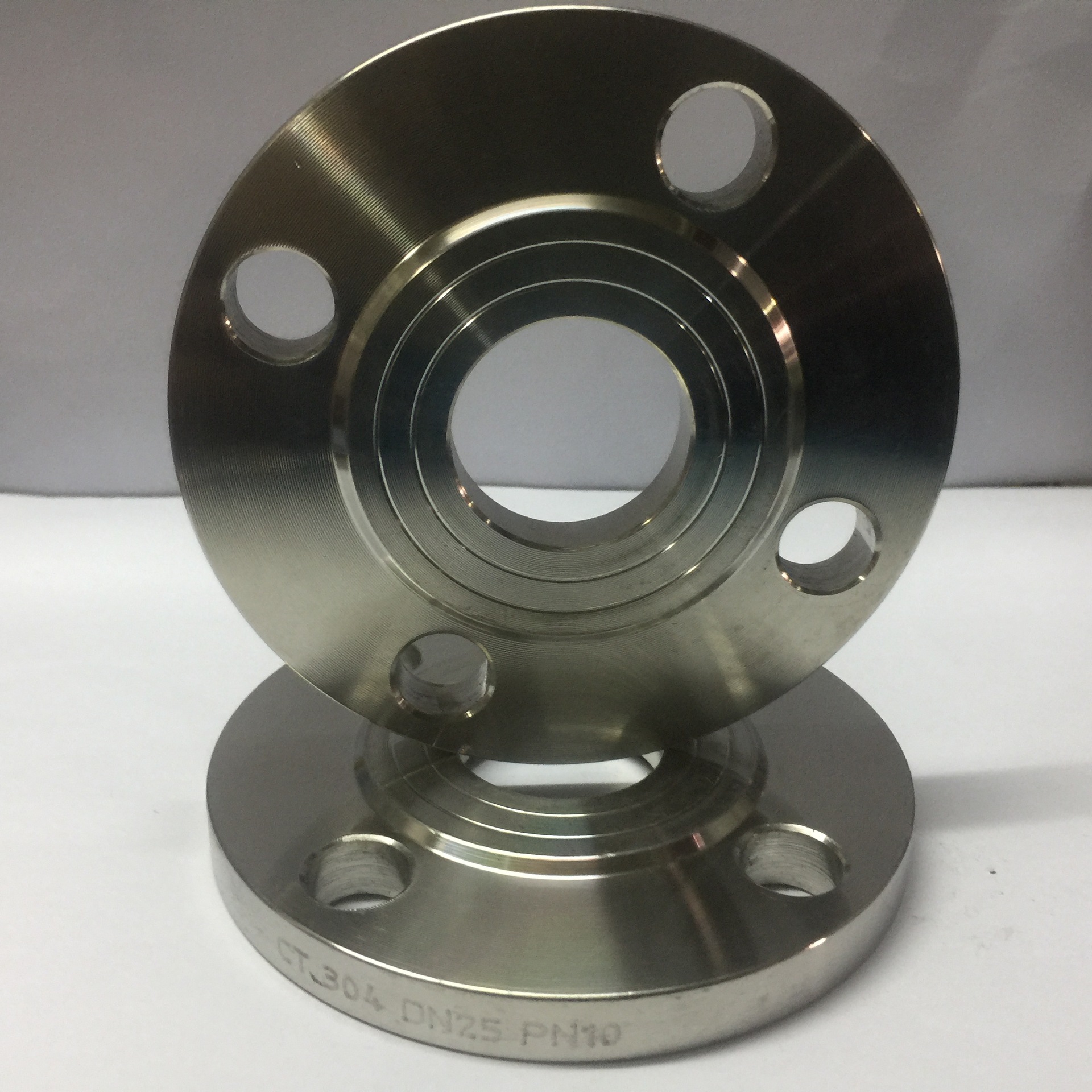

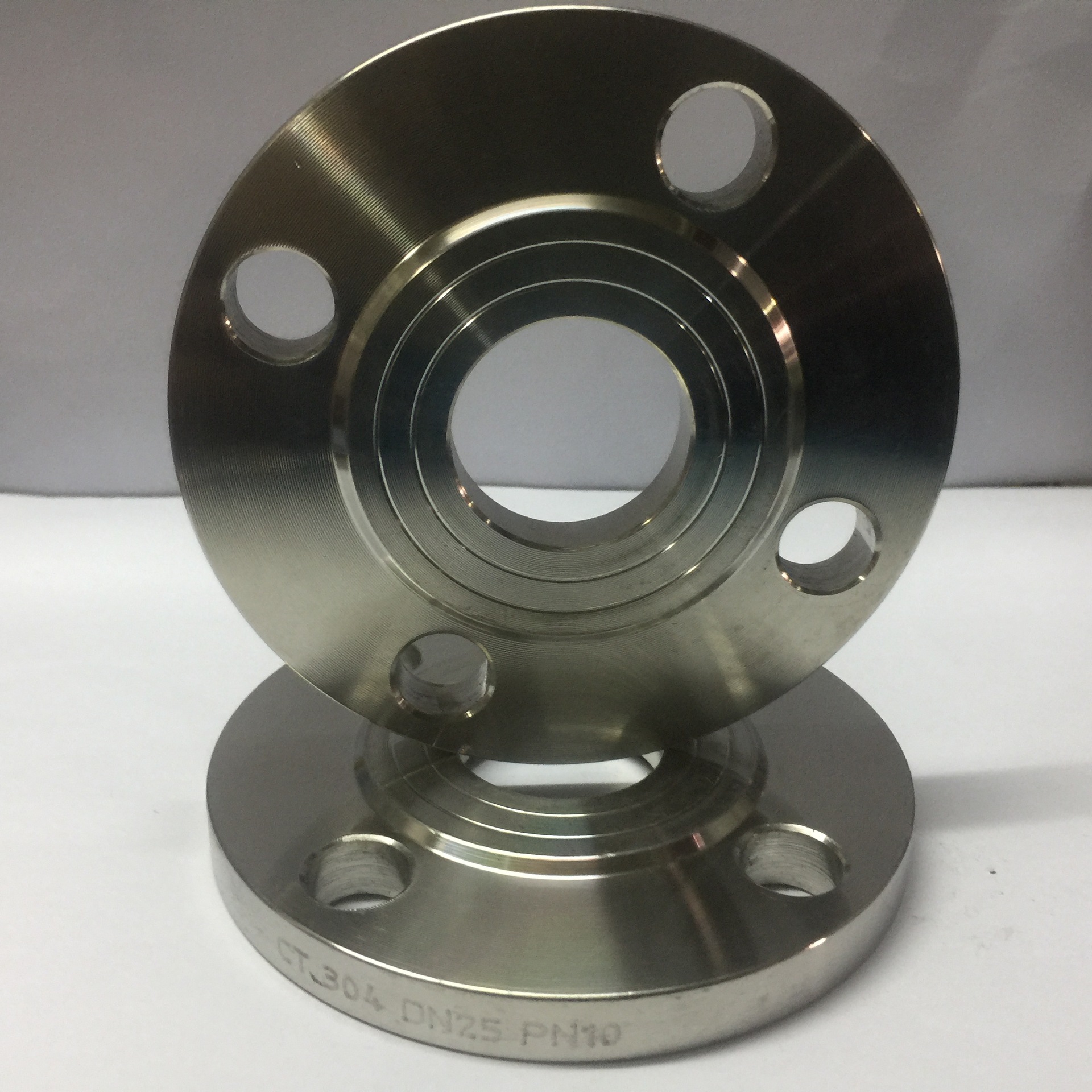

Pipe socket weld fittings, an essential component in piping systems, play a crucial role in connecting pipes, valves, and other equipment in various industries, including oil and gas, chemical processing, and power generation. These fittings are designed with a socket, or a hollowed-out end, into which the pipe is inserted and then welded for a secure connection. The precision engineering and durability of these fittings make them indispensable in high-pressure and high-temperature applications.

Manufacturing pipe socket weld fittings requires state-of-the-art technology and stringent quality control measures. Factories around the world specialize in producing these fittings, each with their unique production techniques and capabilities. In countries like China, India, and the United States, numerous factories have established themselves as global leaders in this domain.

In China, for instance, factories such as Wenzhou Yitong Pipeline Equipment Co., Ltd. and Zhejiang Hongyuan Pipe Fitting Co., Ltd. have gained international recognition for their large-scale production and customization options. They employ advanced forging and machining processes to create a wide range of socket weld fittings, from elbows and tees to reducers and caps, all conforming to international standards like ASME B16 They employ advanced forging and machining processes to create a wide range of socket weld fittings, from elbows and tees to reducers and caps, all conforming to international standards like ASME B16 They employ advanced forging and machining processes to create a wide range of socket weld fittings, from elbows and tees to reducers and caps, all conforming to international standards like ASME B16 They employ advanced forging and machining processes to create a wide range of socket weld fittings, from elbows and tees to reducers and caps, all conforming to international standards like ASME B16

They employ advanced forging and machining processes to create a wide range of socket weld fittings, from elbows and tees to reducers and caps, all conforming to international standards like ASME B16 They employ advanced forging and machining processes to create a wide range of socket weld fittings, from elbows and tees to reducers and caps, all conforming to international standards like ASME B16 pipe socket weld fittings factories.11 and MSS-SP-83.

Indian factories, on the other hand, like Reliant Pipe Fittings and Jain Steels Corporation, are known for their competitive pricing and timely deliveries. They utilize high-grade materials like carbon steel, stainless steel, and alloy steel to manufacture pipe socket weld fittings that withstand harsh environmental conditions.

In the United States, companies like Swagat Steel and Metal and Sandvik Materials Technology cater to the domestic and international markets with their premium quality fittings. Their adherence to American standards like ASTM, ASME, and API ensures the reliability and safety of their products.

Each of these factories invests heavily in research and development to improve the efficiency and durability of their pipe socket weld fittings. They also prioritize environmental sustainability by implementing eco-friendly manufacturing practices and recycling waste materials.

In conclusion, the global market for pipe socket weld fitting factories is vibrant and diverse, with each manufacturer contributing its unique strengths to meet the ever-evolving demands of the industry. These factories not only shape the infrastructure of various sectors but also drive innovation and technological advancement in pipe fitting manufacturing. As global standards continue to evolve, these factories will remain at the forefront, ensuring the seamless integration of pipe systems across the world.

pipe socket weld fittings factories.11 and MSS-SP-83.

Indian factories, on the other hand, like Reliant Pipe Fittings and Jain Steels Corporation, are known for their competitive pricing and timely deliveries. They utilize high-grade materials like carbon steel, stainless steel, and alloy steel to manufacture pipe socket weld fittings that withstand harsh environmental conditions.

In the United States, companies like Swagat Steel and Metal and Sandvik Materials Technology cater to the domestic and international markets with their premium quality fittings. Their adherence to American standards like ASTM, ASME, and API ensures the reliability and safety of their products.

Each of these factories invests heavily in research and development to improve the efficiency and durability of their pipe socket weld fittings. They also prioritize environmental sustainability by implementing eco-friendly manufacturing practices and recycling waste materials.

In conclusion, the global market for pipe socket weld fitting factories is vibrant and diverse, with each manufacturer contributing its unique strengths to meet the ever-evolving demands of the industry. These factories not only shape the infrastructure of various sectors but also drive innovation and technological advancement in pipe fitting manufacturing. As global standards continue to evolve, these factories will remain at the forefront, ensuring the seamless integration of pipe systems across the world.

They employ advanced forging and machining processes to create a wide range of socket weld fittings, from elbows and tees to reducers and caps, all conforming to international standards like ASME B16 They employ advanced forging and machining processes to create a wide range of socket weld fittings, from elbows and tees to reducers and caps, all conforming to international standards like ASME B16

They employ advanced forging and machining processes to create a wide range of socket weld fittings, from elbows and tees to reducers and caps, all conforming to international standards like ASME B16 They employ advanced forging and machining processes to create a wide range of socket weld fittings, from elbows and tees to reducers and caps, all conforming to international standards like ASME B16 pipe socket weld fittings factories.11 and MSS-SP-83.

Indian factories, on the other hand, like Reliant Pipe Fittings and Jain Steels Corporation, are known for their competitive pricing and timely deliveries. They utilize high-grade materials like carbon steel, stainless steel, and alloy steel to manufacture pipe socket weld fittings that withstand harsh environmental conditions.

In the United States, companies like Swagat Steel and Metal and Sandvik Materials Technology cater to the domestic and international markets with their premium quality fittings. Their adherence to American standards like ASTM, ASME, and API ensures the reliability and safety of their products.

Each of these factories invests heavily in research and development to improve the efficiency and durability of their pipe socket weld fittings. They also prioritize environmental sustainability by implementing eco-friendly manufacturing practices and recycling waste materials.

In conclusion, the global market for pipe socket weld fitting factories is vibrant and diverse, with each manufacturer contributing its unique strengths to meet the ever-evolving demands of the industry. These factories not only shape the infrastructure of various sectors but also drive innovation and technological advancement in pipe fitting manufacturing. As global standards continue to evolve, these factories will remain at the forefront, ensuring the seamless integration of pipe systems across the world.

pipe socket weld fittings factories.11 and MSS-SP-83.

Indian factories, on the other hand, like Reliant Pipe Fittings and Jain Steels Corporation, are known for their competitive pricing and timely deliveries. They utilize high-grade materials like carbon steel, stainless steel, and alloy steel to manufacture pipe socket weld fittings that withstand harsh environmental conditions.

In the United States, companies like Swagat Steel and Metal and Sandvik Materials Technology cater to the domestic and international markets with their premium quality fittings. Their adherence to American standards like ASTM, ASME, and API ensures the reliability and safety of their products.

Each of these factories invests heavily in research and development to improve the efficiency and durability of their pipe socket weld fittings. They also prioritize environmental sustainability by implementing eco-friendly manufacturing practices and recycling waste materials.

In conclusion, the global market for pipe socket weld fitting factories is vibrant and diverse, with each manufacturer contributing its unique strengths to meet the ever-evolving demands of the industry. These factories not only shape the infrastructure of various sectors but also drive innovation and technological advancement in pipe fitting manufacturing. As global standards continue to evolve, these factories will remain at the forefront, ensuring the seamless integration of pipe systems across the world. Latest news

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025