Exploring Flangeless Butterfly Valves for Streamlined Fluid Control Solutions in Various Applications

Understanding Flangeless Butterfly Valves A Comprehensive Overview

Butterfly valves are essential components in various industrial applications, particularly for regulating or isolating flow. While many people are familiar with traditional butterfly valves that feature flanges for easy installation, flangeless butterfly valves are becoming increasingly popular due to their unique design and advantages. In this article, we will explore what flangeless butterfly valves are, their features, benefits, and applications.

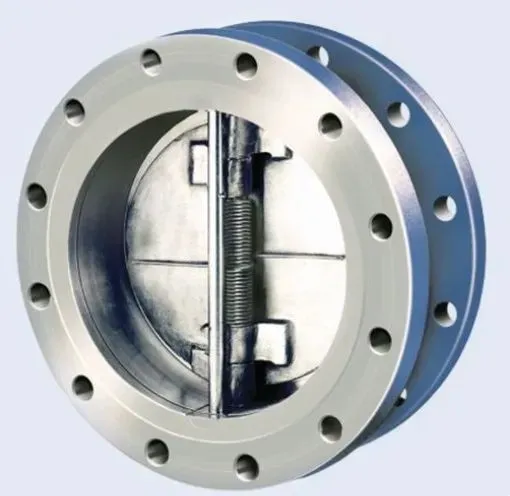

What is a Flangeless Butterfly Valve?

A flangeless butterfly valve is a type of valve that utilizes a disc to control the flow of fluid within a pipeline. Unlike standard butterfly valves that require flanges for secure mounting, flangeless designs rely on other mechanisms for attachment, such as clamps or welds directly to the pipe. This design can offer significant advantages in specific applications, especially where space and weight are critical considerations.

Key Features of Flangeless Butterfly Valves

1. Compact Design Without flanges, these butterfly valves are generally more compact and lightweight, making them suitable for installations with limited space. This feature is particularly beneficial in environments where weight constraints are critical, such as in aerospace or marine applications.

2. Streamlined Installation Flangeless butterfly valves can simplify installation since they do not require additional flange components. This leads to a quicker assembly process and can reduce overall labor costs.

3. Reduced Leakage Potential The design of flangeless valves often entails fewer joints and connections, which can reduce the potential for leaks. This can enhance the overall efficiency and reliability of the system.

4. Versatility Flangeless butterfly valves are available in various materials, including stainless steel, plastic, and other alloys, making them suitable for different fluid types, including corrosive substances or high-temperature applications.

Advantages of Using Flangeless Butterfly Valves

1. Space Efficiency The compact nature of flangeless butterfly valves means they can fit into tighter spaces where traditional valves may not. This is particularly valuable in retrofitting existing systems or in confined installations.

butterfly valve without flange

2. Cost-Effective Solution By eliminating the need for flanges and additional mounting hardware, flangeless butterfly valves can offer a more economical solution for many applications, reducing both material and installation costs.

3. Reduced Weight For applications where weight is a significant factor, such as in transportation or aerospace, the lighter construction of flangeless butterfly valves can lead to significant savings in fuel and operational costs.

4. Enhanced Flow Control The design of the disc allows for precise flow regulation with minimal resistance, leading to better control of processes and improved energy efficiency.

Applications of Flangeless Butterfly Valves

Flangeless butterfly valves are used across a range of industries, including

- Chemical Processing Their ability to withstand corrosive environments makes them ideal for controlling the flow of chemicals in manufacturing processes. - Food and Beverage In hygienic applications, flangeless butterfly valves are used extensively for their ease of cleaning and sanitary design.

- Water Treatment These valves are commonly employed in water and wastewater treatment facilities to manage flow and ensure efficient operation.

- HVAC Systems Flangeless butterfly valves are also relevant in heating, ventilation, and air conditioning systems, where they help regulate the flow of air.

Conclusion

Flangeless butterfly valves are an innovative solution for numerous industrial applications, offering several advantages over traditional flanged designs. Their compact size, streamlined installation process, and reduced leakage potential make them an attractive option for engineers and operators seeking efficiency and reliability. As industries continue to evolve, the demand for versatile and effective flow control solutions like flangeless butterfly valves is likely to grow, cementing their place in modern engineering practices.

-

3-types-of-check-valves-maintenance-tipsNewsAug.23,2025

-

ball-valves-types-with-trunnion-mounted-designNewsAug.23,2025

-

butterfly-valve-company-production-capabilitiesNewsAug.23,2025

-

fisher-globe-valve-technical-specificationsNewsAug.23,2025

-

types-of-gaskets-for-flanges-selection-guideNewsAug.23,2025

-

wedge-gate-valve-suppliers-quality-standardsNewsAug.23,2025

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025