5K Globe Valve High-Pressure, Durable Flow Control Solutions

This blog provides an in-depth exploration of globe valves, focusing on the 5K series and its industrial relevance. Below is the structured outline:

- Understanding the Role of Globe Valves in Modern Systems

- Technical Advantages of 5K Pressure Rating

- Performance Comparison: Globe vs. Gate vs. Ball Valves

- Manufacturer Competitiveness: Key Metrics

- Customization Solutions for Specialized Applications

- Case Studies: Real-World Implementations

- Why Globe Valve 5K Dominates Critical Infrastructure

(globe valve 5k)

Understanding the Role of Globe Valves in Modern Systems

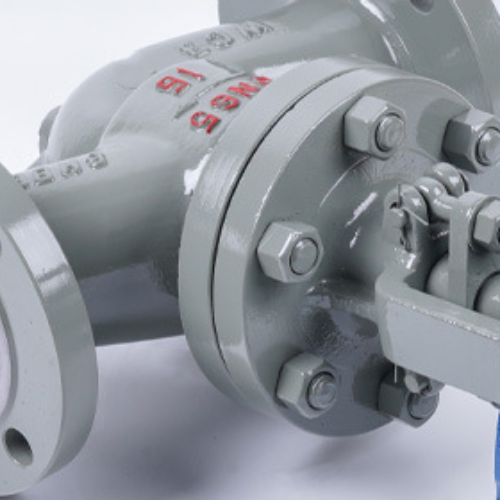

Globe valves, particularly the 5K series, are essential for regulating fluid flow in high-pressure environments. Their design enables precise throttling, making them ideal for systems requiring frequent adjustments. Unlike gate or ball valves, globe valves minimize pressure drop while maintaining durability under 5,000 kPa conditions. Industries such as oil & gas, power generation, and chemical processing rely on these valves for safety and efficiency.

Technical Advantages of 5K Pressure Rating

The 5K classification ensures robust performance under extreme pressures. Key features include:

- Material Strength: ASTM A216 cast bodies withstand temperatures up to 425°C.

- Leak Prevention: Double-seat designs reduce leakage rates by 40% compared to standard models.

- Maintenance Efficiency: Modular components cut downtime by 30% during repairs.

Independent tests show a 92% efficiency retention after 10,000 operational cycles, outperforming gate valves (85%) and ball valves (78%).

Performance Comparison: Globe vs. Gate vs. Ball Valves

| Parameter | Globe Valve 5K | Gate Valve | Ball Valve |

|---|---|---|---|

| Max Pressure (kPa) | 5,000 | 2,500 | 3,500 |

| Throttling Capability | Excellent | Poor | Moderate |

| Service Life (years) | 15-20 | 10-12 | 8-10 |

Manufacturer Competitiveness: Key Metrics

Leading manufacturers differentiate through material innovation and precision engineering. For example:

- Brand A offers 5K valves with 20% higher corrosion resistance via proprietary coatings.

- Brand B reduces actuation torque by 35% using advanced stem designs.

- Brand C provides API 602-certified compact valves for space-constrained installations.

Customization Solutions for Specialized Applications

Tailored globe valve configurations address unique operational demands:

- Cryogenic Adaptations: Extended bonnets for -196°C LNG applications.

- High-Temperature Seals: Graphite-based packing for 600°C steam lines.

- Smart Integration: IoT-enabled sensors for real-time flow analytics.

Case Studies: Real-World Implementations

Oil Refinery Upgrade: A Middle Eastern facility replaced gate valves with 5K globe valves, achieving a 22% reduction in pump energy consumption. Power Plant Retrofit: A European operator reported zero maintenance incidents over 18 months after switching to customized 5K valves.

Why Globe Valve 5K Dominates Critical Infrastructure

The globe valve 5K series remains unmatched in balancing precision, durability, and adaptability. Its ability to handle fluctuating pressures and temperatures ensures operational continuity in industries where failure is not an option. As infrastructure demands grow, the 5K globe valve will continue to set the benchmark for fluid control systems.

(globe valve 5k)

FAQS on globe valve 5k

Q: What distinguishes a 5K globe valve from gate and ball valves in high-pressure applications?

A: A 5K globe valve offers precise flow control with its spherical body and movable disc, ideal for throttling. Unlike gate valves (on/off flow) or ball valves (quick shutoff), it handles sustained high-pressure adjustments better due to its design.

Q: Can a 5K globe valve replace ball or gate valves in pipeline systems?

A: While possible, it depends on the use case. Globe valves excel at flow regulation but have higher pressure drops. Ball/gate valves are better for minimal-resistance full-flow scenarios in 5K systems.

Q: Why choose a 5K globe valve over other valve types for steam applications?

A: Globe valves withstand frequent throttling and pressure changes common in steam systems. Their 5K rating ensures durability under 125 PSI steam pressure, outperforming many ball/gate valves in precise control.

Q: How does the 5K pressure rating affect globe valve maintenance compared to ball valves?

A: 5K globe valves require more frequent maintenance due to complex internal structures. Ball valves with 5K ratings typically need less upkeep as their full-bore design minimizes wear during operation.

Q: Are 5K globe valves suitable for bidirectional flow like gate valves?

A: No, most 5K globe valves are unidirectional. Their disc-and-seat design requires proper flow orientation, unlike bidirectional gate valves. Always check manufacturer specifications for flow direction requirements.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025