Innovative Bellows-Sealed Gate Valve for Improved Performance and Leakage Protection

Understanding Bellows Seal Gate Valves

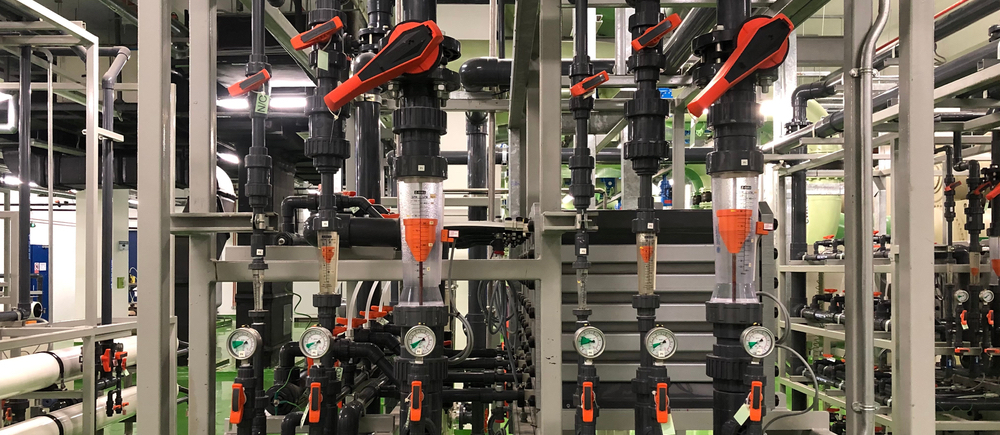

Bellows seal gate valves are vital components in various industrial applications, particularly where leakage prevention and the management of high-pressure environments are critical. These valves provide a reliable sealing solution, ensuring that fluids or gases remain contained within the system.

One of the primary features of a bellows seal gate valve is its innovative sealing mechanism, which is designed using a metallic bellows. Unlike traditional gate valves that rely on packing to create a seal, the bellows act as a flexible barrier, allowing for better performance in challenging conditions. This design eliminates the possibility of leakage that often accompanies the wear and deterioration of packing materials over time.

The bellows, typically made from materials like stainless steel, are constructed in a way that allows for significant flexibility while maintaining a strong seal. This enables the valve to effectively handle not just liquids, but also gases and steam, making it versatile for various applications, including chemical processing, oil and gas exploration, and power generation.

In operation, the bellows seal gate valve functions like a standard gate valve, operating on the principle of lifting a gate out of the flow path to allow for full flow. When the valve is closed, the gate sits between two seats, creating a tight seal. The bellows surround the stem of the valve, preventing any fluid or gas from escaping into the atmosphere. This makes bellows seal gate valves particularly suitable for use in environmentally sensitive areas where leaks could cause significant harm.

bellows seal gate valve

Another benefit of these valves is their durability. The robust materials used in their construction allow them to withstand extreme conditions, including high temperatures and pressures. This resilience extends the operational life of the valve, leading to reduced maintenance needs and costs over time.

Furthermore, the design of the bellows seal gate valve minimizes operational torque, meaning that less force is required to open and close the valve. This not only prolongs the life of the actuator but also enhances the safety of the system, as operators can manage the valve more easily without the risk of damage.

Despite their numerous advantages, selecting the right bellows seal gate valve requires careful consideration of several factors. These include the nature of the media being transported, the operating temperature and pressure, and the overall system design. Consulting with manufacturers and engineers can help ensure that the right type of valve is chosen, one that meets specific operational requirements while maximizing reliability and performance.

In summary, bellows seal gate valves stand out due to their exceptional sealing capabilities, durability, and efficient operation. As industries continue to prioritize safety and environmental protection, these valves will play an increasingly important role in ensuring effective fluid and gas management in various applications.

-

The Versatility of Ball Valves in Fluid Control SystemsNewsJun.10,2025

-

The Practical Benefits of Centerline Butterfly ValvesNewsJun.10,2025

-

The Benefits of Bellows Seal Globe Valves for Industrial SystemsNewsJun.10,2025

-

The Advantages of Offset Butterfly ValvesNewsJun.10,2025

-

Ductile Gate Valves: Strong, Reliable, and Essential for Every SystemNewsJun.10,2025

-

Cast Iron Gate Valves: A Reliable Solution for Every SystemNewsJun.10,2025

-

Why Choose a Brass Gate Valve for Superior Performance and DurabilityNewsMay.09,2025