Low Pressure Check Valve Suppliers and Manufacturers for Reliable Solutions

Low Pressure Check Valve Manufacturers Ensuring Efficiency and Safety

Low pressure check valves play a critical role in countless industrial applications, preventing backflow and ensuring that fluids move in the desired direction. As demand for these components grows, so does the need for reliable manufacturers capable of delivering high-quality check valves that meet industry standards. This article explores the significance of choosing reputable low pressure check valve manufacturers and the factors influencing their performance and quality.

Importance of Low Pressure Check Valves

In various systems, including water treatment plants, HVAC systems, and chemical processing, low pressure check valves are essential for maintaining system integrity. Their primary function is to prevent reverse flow, which can lead to contamination, equipment damage, and inefficient system performance. By allowing fluid to flow in only one direction, these valves ensure that processes run smoothly and efficiently.

Key Features of Quality Manufacturers

When assessing low pressure check valve manufacturers, it is essential to consider several factors that contribute to the quality and reliability of their products

1. Material Quality

The materials used in the construction of check valves are paramount. High-quality manufacturers typically utilize durable materials such as stainless steel, brass, and PVC, which can withstand various environments and fluid types. It is essential to choose a manufacturer that understands the specific requirements of your application, including temperature, pressure, and chemical compatibility.

2. Design and Innovation

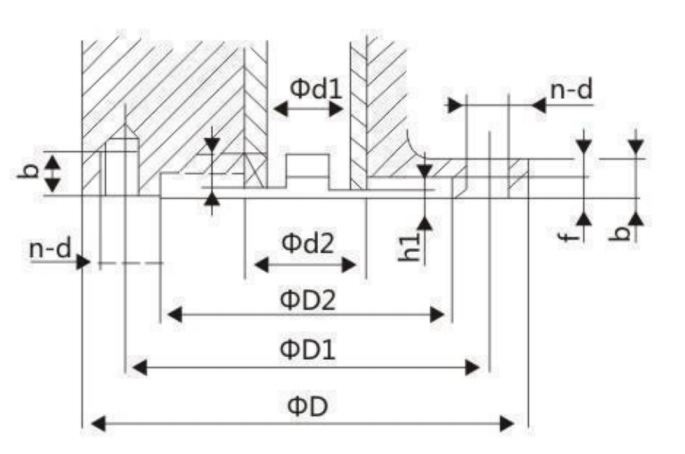

low pressure check valve manufacturers

Forward-thinking manufacturers continuously invest in research and development to improve valve design and performance. Advanced technology can lead to more efficient flow dynamics, reduced leakage rates, and longer service life. Selecting a manufacturer that prioritizes innovation ensures that you receive cutting-edge products that can enhance your system’s efficiency.

3. Compliance with Standards

Reputable manufacturers adhere to industry standards and regulations, such as ANSI, API, and ISO certifications. Compliance with these standards is critical for safety and reliability, especially in critical applications such as oil and gas, pharmaceuticals, and food processing. When selecting a manufacturer, verify their certifications to ensure their products meet the necessary safety and quality benchmarks.

4. Customization Options

Every application has unique requirements. Leading manufacturers often provide customization options to tailor check valves according to specific needs. This flexibility can include adjustments in size, flow rate, and connection type, ensuring that the valve integrates seamlessly into your system.

5. Customer Support and Service

A reliable manufacturer does not just deliver products but also offers robust customer support. This includes responding to inquiries, assisting with installation, and providing after-sales service. Manufacturers that prioritize customer service build lasting relationships and help customers troubleshoot any issues that arise.

Conclusion

Selecting the right low pressure check valve manufacturer is crucial for ensuring the safety and efficiency of your systems. By focusing on material quality, innovative design, compliance with industry standards, customization options, and customer support, you can make an informed choice that will lead to long-term success. As industries continue to evolve, the demand for high-quality check valves will only increase, making it essential to partner with manufacturers that prioritize excellence in their products and services.

-

The Versatility of Ball Valves in Fluid Control SystemsNewsJun.10,2025

-

The Practical Benefits of Centerline Butterfly ValvesNewsJun.10,2025

-

The Benefits of Bellows Seal Globe Valves for Industrial SystemsNewsJun.10,2025

-

The Advantages of Offset Butterfly ValvesNewsJun.10,2025

-

Ductile Gate Valves: Strong, Reliable, and Essential for Every SystemNewsJun.10,2025

-

Cast Iron Gate Valves: A Reliable Solution for Every SystemNewsJun.10,2025

-

Why Choose a Brass Gate Valve for Superior Performance and DurabilityNewsMay.09,2025