Innovative Steel Strainer Designs for Enhanced Filtration and Durability

The Importance of Steel Strainers in Modern Industry

In the myriad of components that make up our industrial landscape, the steel strainer holds a pivotal role. Often overlooked, this simple yet effective device is indispensable in ensuring the efficiency and longevity of various mechanical systems. Steel strainers are designed to filter out unwanted debris and particulate matter from liquids or gases, preventing damage to equipment and ensuring optimal operation. Their significance spans multiple industries, including oil and gas, water treatment, food processing, and pharmaceuticals.

What is a Steel Strainer?

A steel strainer is essentially a device used to remove solid particles from a fluid stream, typically employing a mesh or perforated plate made of steel. This filtration process is crucial in protecting downstream equipment such as pumps, valves, and heat exchangers that could be adversely affected by contamination. Steel, as a material, is chosen for its durability, resistance to corrosion, and ability to withstand high temperatures — attributes that make steel strainers suitable for demanding environments.

Types of Steel Strainers

There are several types of steel strainers, each designed for specific applications

1. Y-Strainers Shaped like a Y, these are often used in horizontal piping systems. They allow for easy cleaning and maintenance while effectively filtering out particles.

2. Basket Strainers These feature a basket-shaped component where debris accumulates. They are commonly used in larger pipelines and can handle substantial flow rates.

3. Tube Strainers These are used in applications where space is limited. They fit into the system in a tubular configuration, providing a compact solution for effective filtration.

4. Inline Strainers As the name suggests, these are installed directly in-line with the flow of the fluid. They are useful in applications requiring minimal disruption to the flow path.

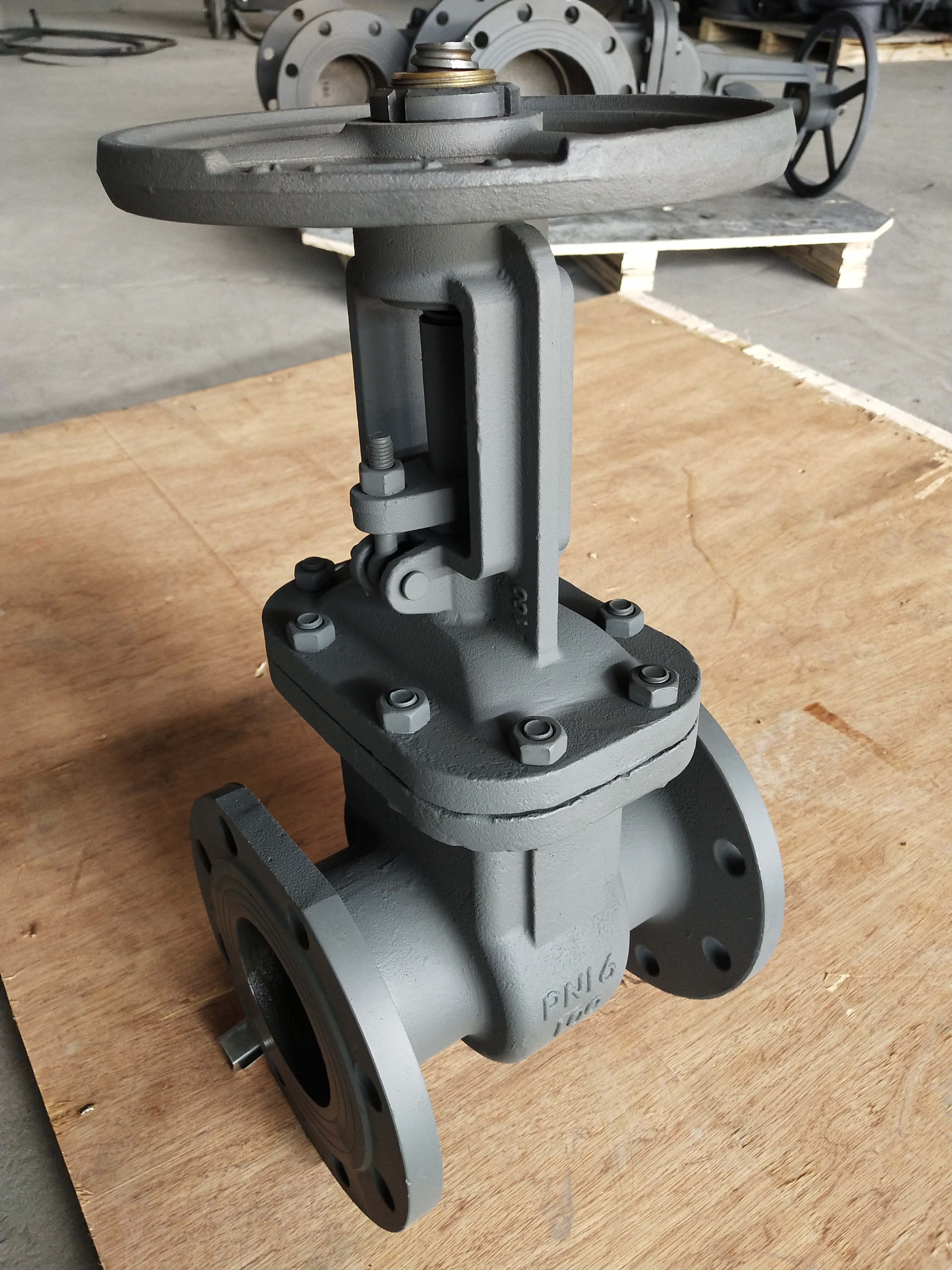

steel strainer

Applications in Various Industries

In the oil and gas sector, steel strainers are critical for protecting pipeline systems from contaminants that could cause costly shutdowns. They filter out sand, silt, and other particles that naturally occur in extracted crude oil or natural gas.

In water treatment facilities, strainers ensure that only clean water is processed, preventing clogging in filtration systems and protecting pumps from damage. This is crucial for maintaining the quality of water supplied to communities and ensuring compliance with environmental standards.

The food processing industry also benefits from steel strainers, where hygiene and safety are paramount. Strainers help eliminate foreign particles, ensuring that the products are safe for consumption and meet regulatory requirements.

In the pharmaceutical industry, strainers play a vital role in the production of medicines and vaccines, where any contamination could be catastrophic. They help guarantee the integrity of the substances being processed, which is crucial for patient safety.

Maintenance and Best Practices

To ensure the efficiency of steel strainers, regular maintenance is essential. Cleaning or replacing the strainer elements periodically will prevent clogs and ensure that the equipment operates smoothly. The frequency of maintenance will depend on the specific application and the level of contamination in the fluids being filtered.

Moreover, choosing the right type of strainer for a specific application is crucial. Oversized or incorrectly designed strainers can lead to inefficiencies, while undersized ones may not sufficiently filter out contaminants.

Conclusion

Steel strainers are a vital component in modern industrial systems, offering significant protection against contaminants in various fluid applications. Their robust design and effectiveness in filtering debris not only enhance equipment longevity but also contribute to operational efficiency. As industries continue to evolve, the importance of steel strainers will undoubtedly grow, underscoring the need for quality products and diligent maintenance in ensuring seamless industrial operations. Whether in oil fields, water treatment plants, or food and pharmaceutical production lines, steel strainers are indispensable allies in the quest for performance and reliability.

-

3-types-of-check-valves-maintenance-tipsNewsAug.23,2025

-

ball-valves-types-with-trunnion-mounted-designNewsAug.23,2025

-

butterfly-valve-company-production-capabilitiesNewsAug.23,2025

-

fisher-globe-valve-technical-specificationsNewsAug.23,2025

-

types-of-gaskets-for-flanges-selection-guideNewsAug.23,2025

-

wedge-gate-valve-suppliers-quality-standardsNewsAug.23,2025

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025