Types, structural features and differences of wedge gate valves

The gate of the wedge gate valve is wedge-shaped, which can be seen from the force analysis of the wedge gate. The downward thrust of the valve stem decomposes the positive pressure on the valve seat sealing surface, which has an auxiliary sealing effect on low-pressure media. It avoids the poor sealing effect of low-pressure media similar to flat gate valves. At high pressure, the medium pressure is used to push the gate to press on the outlet valve seat to maintain the seal.

The wedge gate leaves the valve seat at the moment of opening, reducing the wear of the sealing surface. Cobalt-based alloy is welded on the sealing surface to improve the high temperature performance, fatigue resistance, corrosion resistance and sealing surface hardness of the sealing surface.

Standard for wedge gate valve: GB /T12234-2019 Steel gate valve with bolted valve cover for petroleum and natural gas industry. GB/T12232-2005 General valve flange connection iron gate valve. API STANDARD 600-2015.

The gate of the wedge gate valve is divided into: single wedge gate. Elastic wedge gate. Double wedge gate. The commonly used flange cast steel wedge gate valve combination models are as follows:

Flange rising stem wedge elastic gate Z40H

Flange rising stem wedge rigid single gate Z41H

Flange rising stem wedge rigid double gate Z42H

Flange non-rising stem wedge rigid single gate Z45H

Flange non-rising stem wedge rigid double gate Z46H

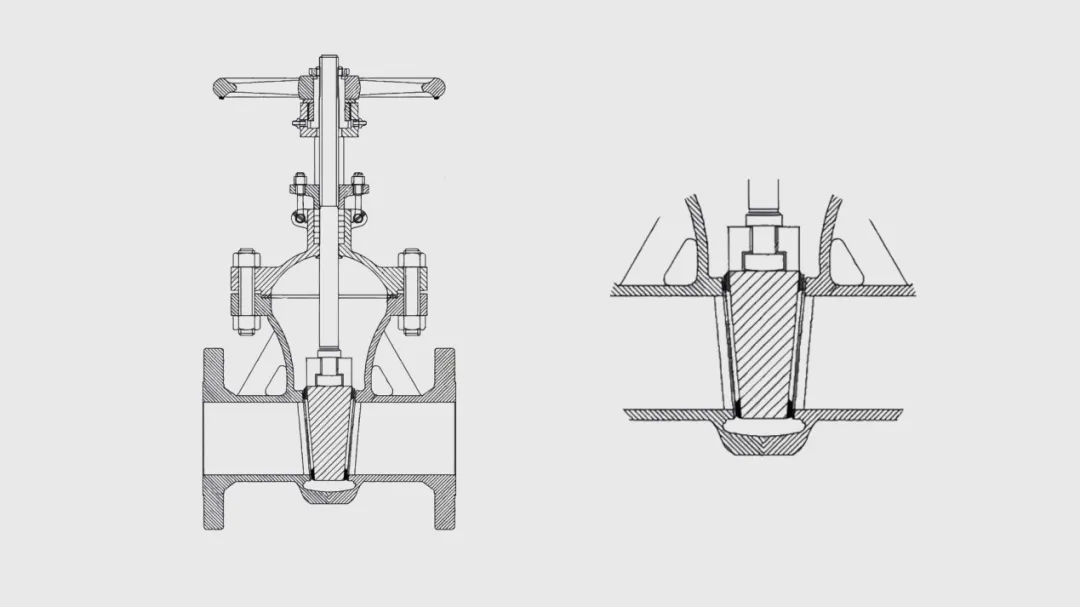

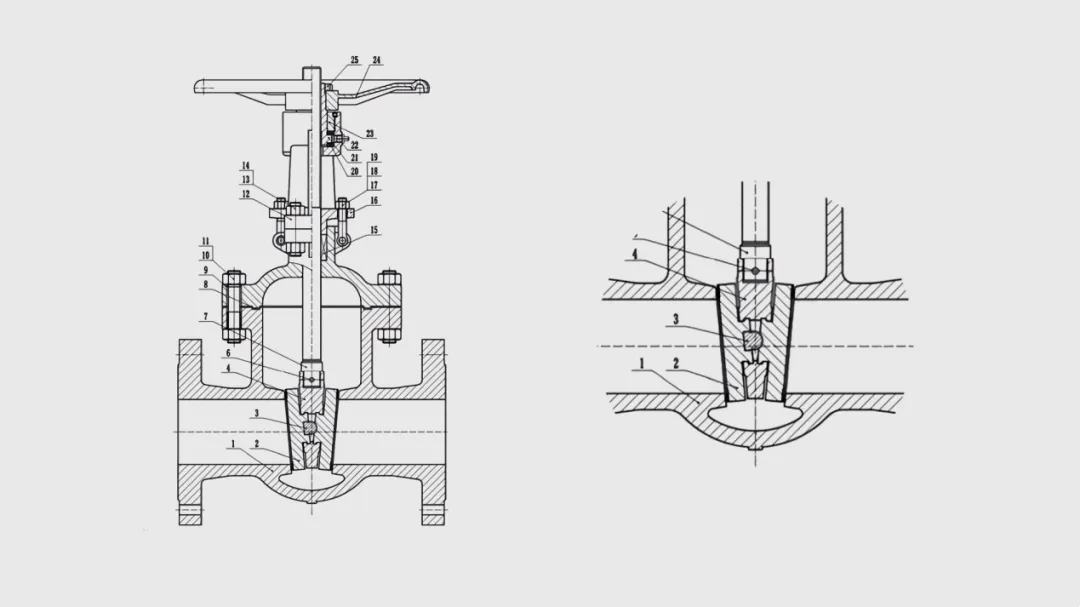

- Single wedge gate, that is, rigid single gate. The gate is an integral wedge, with an inverted T-shaped groove at the upper end of the gate, which is connected to the valve stem through the inverted T-shaped groove. The sealing surfaces on both sides of the wedge gate are sealed with the valve seats on both sides respectively. The inverted T-shaped groove of the gate and the valve stem are movably connected, which can compensate for the errors caused by processing, so that the sealing surface of the gate and the sealing surface of the valve seat fit together better to complete the sealing.

- The gates of concealed stem gate valves and rising stem gate valves are different. The concealed stem gate has a through hole in the direction of the valve stem axis, which can accommodate the valve stem when the gate is opened.

- 2. The wedge-type elastic gate is based on a rigid single gate, and an annular groove is machined on the vertical bisecting plane of the gate, and only the center of the gate is connected together. The gate sealing surface has a certain elastic deformation capacity. When the gate is closed, the deviation of the wedge angle between the gate sealing surface and the valve seat sealing surface can be compensated, thereby ensuring the sealing surface effect.

- When there is a high-temperature medium in the pipeline, the gate, valve stem and other components expand. It may cause the gate to swell with the valve seat when it is in the closed position. The gate cannot be opened normally. The elastic deformation ability of the elastic gate can effectively avoid the gate from getting stuck.

- The elastic gate has good sealing performance and small switching torque, which is suitable for high-temperature pipelines.

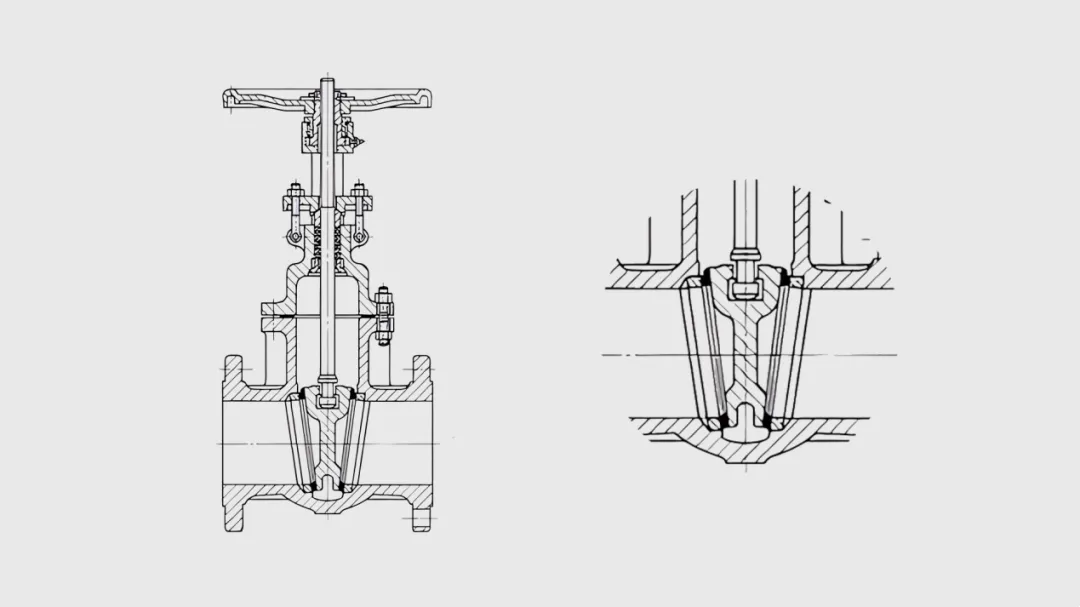

- 3. The wedge-type double gate is to disconnect the middle connecting part of the elastic gate, forming two gates on the inlet and outlet sides. The middle is connected by a spherical top core to form a wedge-shaped gate. When the gate is closed, due to the spherical top core structure between the inner sides of the two gates, as the gate descends, the distance between them gradually decreases, and the spherical top core structure pushes the two gates outward. The sealing surfaces of the gates at the inlet and outlet ends are pressed against the valve seat to complete the sealing.

- When the gate is opened, since the spherical top center structure does not have the inclination angle of self-locking effect like the wedge-shaped sealing surface, after the gate is slightly loosened with a small force, the two movable gates under fluid pressure can move inward to release the friction state with the valve seat port, which not only saves effort in opening operation, but also reduces the friction between the gate and the valve seat port, thereby reducing wear.

- The gates on both sides are movably connected, and their compensation deformation capacity far exceeds that of elastic gates. It can better complete the seal with the valve seat and reduce internal leakage. It is not easy to get stuck when the temperature changes, and at the same time reduces the wear of the sealing surface. However, it is easy to bond in easy-to-crystallize, viscous media, affecting the seal.

- From the wedge-type rigid single gate to the wedge-type elastic gate, and then to the wedge-type double gate, the automatic compensation of the gate and valve seat processing errors has been gradually solved, and the gate valve can adapt to the medium from normal temperature to high temperature. However, the gate structure is becoming more and more complex and the cost is getting higher and higher. Therefore, it is best to choose a gate valve that suits your working conditions.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsՆորություններJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesՆորություններJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlՆորություններJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesՆորություններJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyՆորություններJul.09,2025

-

Everything You Need to Know About Butterfly ValvesՆորություններJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesՆորություններJul.08,2025