Floating Ball Valve: Compact, Durable Flow Control Solutions

Understanding the Floating Ball Valve: An Industry Overview

The industrial valve market, a critical component in virtually every sector from oil and gas to water treatment, is constantly evolving, driven by demands for greater efficiency, safety, and environmental compliance. Among the myriad valve types, the floating ball valve stands out as a highly versatile and widely adopted solution for fluid control. Characterized by a ball that floats freely within the valve body, it relies on upstream pressure to push the ball against the downstream seat, creating a tight seal. This inherent design simplicity contributes to its reliability and cost-effectiveness across a diverse range of applications.

Current industry trends underscore a growing preference for resilient and high-performance valve solutions that can withstand challenging operational environments. There's a significant drive towards automation and digitalization in process industries, demanding valves that offer precise control and integration capabilities. Furthermore, stringent regulatory frameworks related to emissions, leakages, and safety standards are compelling manufacturers to innovate with advanced materials and sophisticated designs. The market for floating ball valve solutions is seeing robust growth, propelled by infrastructure development, expansion in chemical and petrochemical plants, and increasing investments in water and wastewater management. End-users are increasingly prioritizing valves that offer extended service life, reduced maintenance, and superior performance under extreme conditions.

The importance of selecting a high-quality, reliable floating ball valve cannot be overstated. In critical applications, valve failure can lead to significant operational disruptions, safety hazards, environmental damage, and substantial financial losses. Therefore, a deep understanding of valve design, material compatibility, manufacturing processes, and testing standards is paramount for B2B decision-makers and technical personnel. This includes assessing factors such as pressure ratings, temperature ranges, flow characteristics, and specific media compatibility to ensure optimal system performance and longevity.

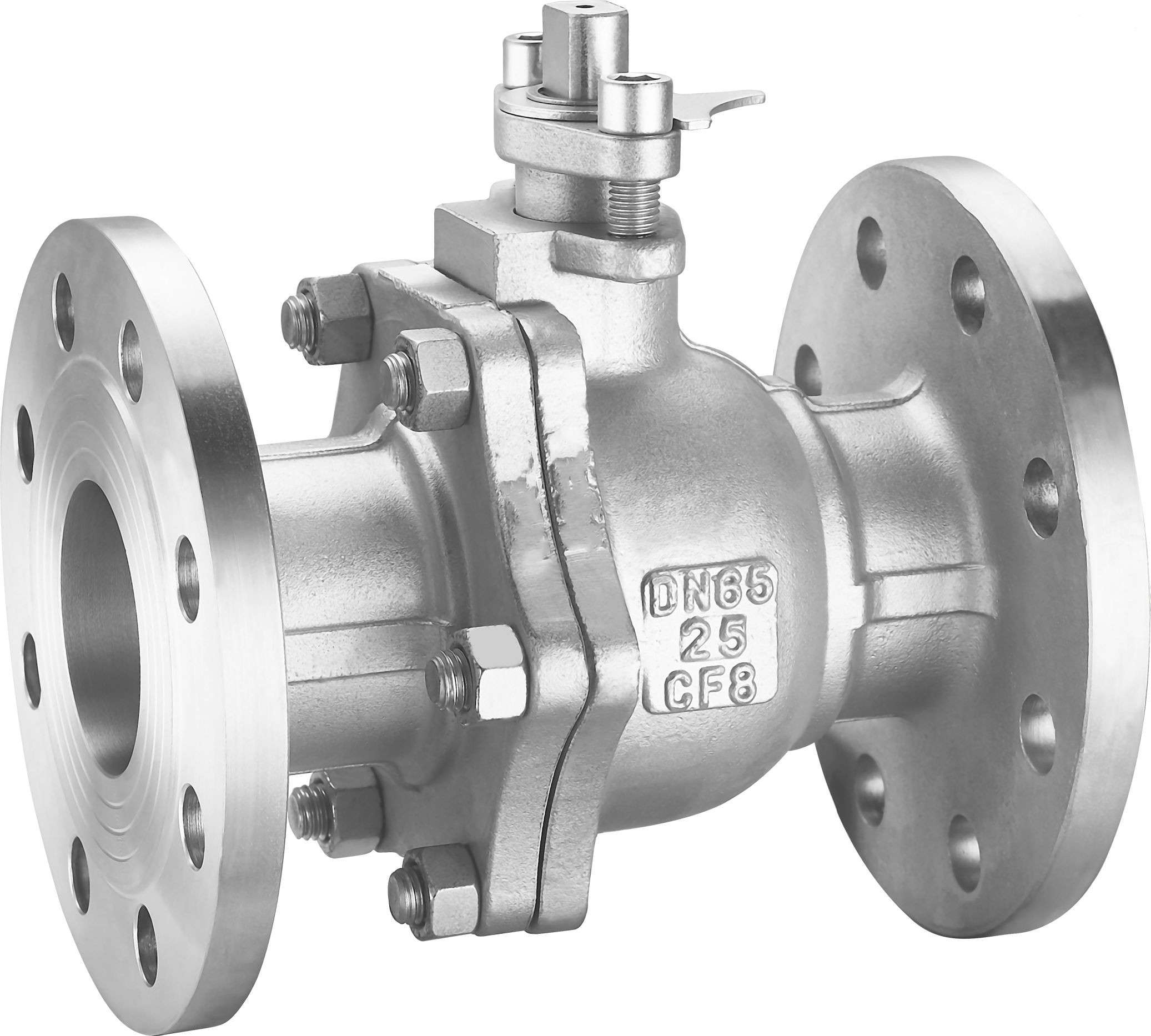

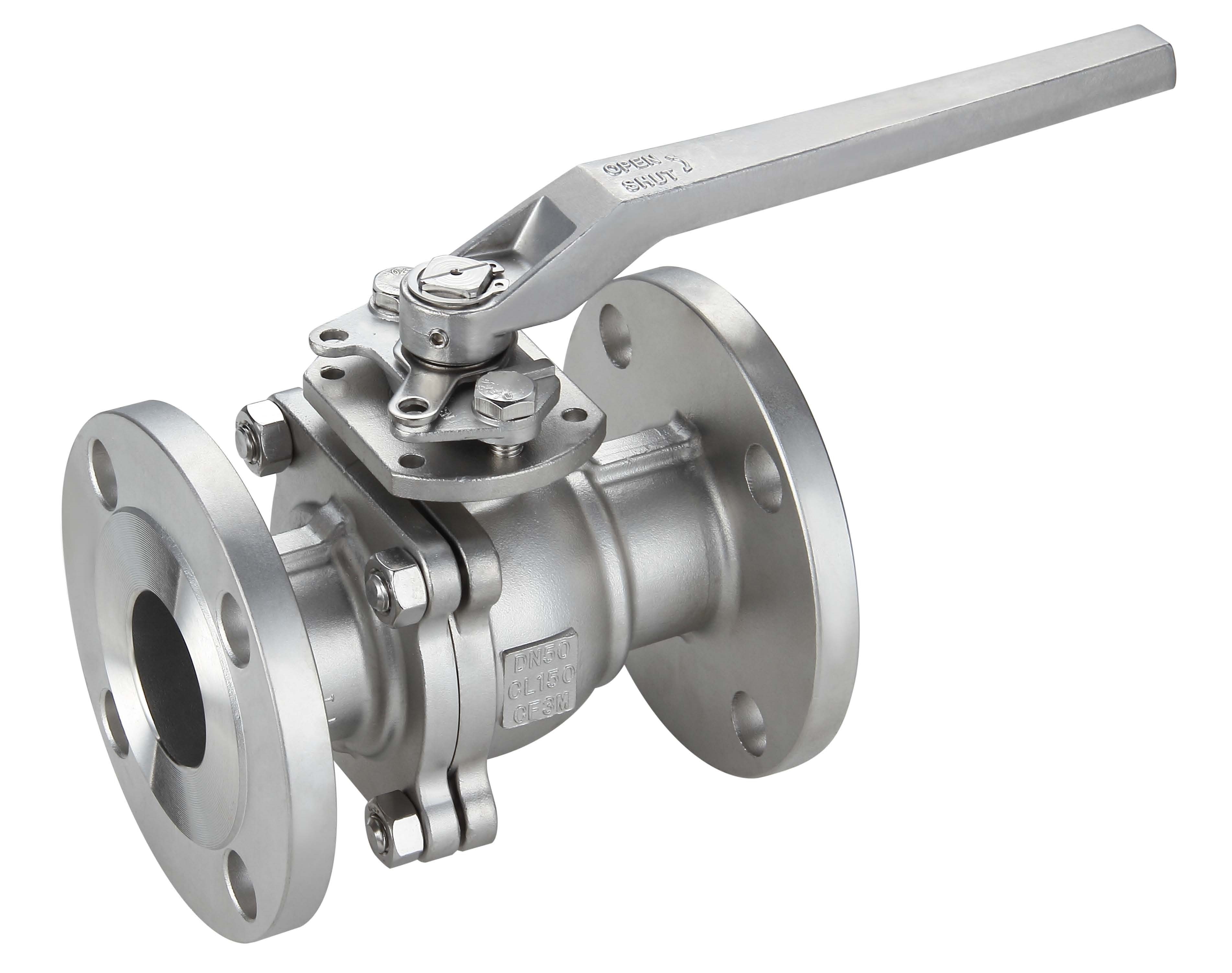

The Q41F-150 300 600LB ANSI Floating Ball Valve: Engineered Excellence

The Q41F-150 300 600LB ANSI floating ball valve represents a pinnacle of engineering and manufacturing precision, designed to meet the rigorous demands of various industrial applications. This specific model adheres to the American National Standards Institute (ANSI) pressure classes 150, 300, and 600LB, signifying its capability to handle a wide spectrum of pressure conditions encountered in pipelines and process systems. The 'F' in Q41F denotes its floating ball design, while '41' typically refers to the structure of the valve, and 'Q' for 'qiufa' or ball valve in Chinese industry standards.

Technical Specifications and Design Principles

The design of the Q41F series incorporates a full bore or reduced bore option, depending on the application's flow requirements. A full bore design ensures minimal pressure drop and maximum flow capacity, making it ideal for applications where pigging is required or where fluid flow must not be impeded. Reduced bore designs, while offering a slight restriction, are more compact and cost-effective for general isolation tasks. The core principle of a floating ball valve relies on the upstream fluid pressure acting on the surface of the ball, pushing it firmly against the downstream seat. This self-compensating seating mechanism provides a tight shut-off, even under fluctuating pressure conditions. For high-pressure applications, the seating materials are carefully selected for their resilience and resistance to deformation, ensuring long-term sealing integrity.

Seat retention and stem sealing are critical aspects. The Q41F series utilizes advanced seat materials such as PTFE, RPTFE, PEEK, and Nylon, chosen for their chemical resistance, temperature capabilities, and low friction characteristics. The stem, which connects the operating mechanism to the ball, is typically anti-blowout designed, a crucial safety feature that prevents the stem from expelling under pressure. Furthermore, a double-sealing arrangement, often involving O-rings and gland packing, ensures zero stem leakage, adhering to strict environmental and safety protocols.

Detailed Manufacturing Process

- Material Sourcing and Preparation: The process begins with sourcing high-grade raw materials. For a stainless steel ball float valve, this would typically involve AISI 304, 316, or specialized alloys like Duplex or Super Duplex stainless steel, chosen for superior corrosion resistance and mechanical properties. Carbon steel (e.g., A216 WCB) is also widely used for general service. Forged components (e.g., A105N) offer enhanced strength and integrity, while cast components (e.g., WCB) provide cost-effectiveness for larger sizes.

- Casting/Forging: Valve bodies and end connections are either precision cast or forged. Casting involves pouring molten metal into molds to create the initial shape, followed by extensive quality checks for defects. Forging involves mechanically deforming solid metal under high pressure to create a denser, stronger, and more uniform grain structure, ideal for high-pressure and critical applications.

- CNC Machining: Advanced Computer Numerical Control (CNC) machining centers are used to achieve precise dimensions and surface finishes for critical components such as the ball, stem, and seats. This ensures accurate alignment, tight tolerances, and optimal sealing performance, directly impacting the valve's lifespan and operational efficiency.

- Assembly: Components are meticulously assembled in a clean environment. This involves inserting the ball, seats, stem, and packing, ensuring correct orientation and torque values for fasteners. For specialized applications, cleanroom assembly may be required to prevent contamination.

- Testing and Quality Control: Every Q41F-series floating ball valve undergoes rigorous testing in accordance with international standards such as API 598 (Valve Inspection and Test), API 6D (Pipeline Valves), and ISO 5208 (Pressure Testing of Industrial Valves). This includes:

- Hydrostatic Shell Test: Verifies the integrity of the valve body and its ability to withstand specified pressures without leakage.

- High-Pressure Gas Seat Test: Confirms the tight shut-off capability of the seats against high-pressure gas (e.g., nitrogen), identifying even minute leakages.

- Low-Pressure Air Seat Test: Checks seat integrity at lower pressures, crucial for preventing fugitive emissions.

- Fugitive Emissions Testing (e.g., ISO 15848-1): For applications requiring ultra-low leakage, ensuring environmental compliance.

- Non-Destructive Examination (NDE): Techniques like radiographic testing (RT), ultrasonic testing (UT), magnetic particle testing (MT), and penetrant testing (PT) are applied to detect internal and surface defects in castings and forgings.

- Surface Treatment and Finishing: Depending on the material and application, valves may undergo surface treatments such as passivation for stainless steel, painting for carbon steel, or specialized coatings for enhanced corrosion resistance or reduced friction.

- Final Inspection and Packaging: Before shipment, each valve undergoes a final visual inspection and is carefully packaged to prevent damage during transit, often with protective caps for flanges and ends.

This meticulous manufacturing and testing regime ensures that the Q41F-series floating ball valve not only meets but often exceeds industry standards for performance, reliability, and longevity, typically offering a lifespan of 15-25 years under normal operating conditions with proper maintenance.

Performance, Advantages, and Application Versatility

The Q41F-150 300 600LB ANSI floating ball valve is celebrated for its robust performance characteristics and inherent advantages that make it suitable for a vast array of industrial applications. Its quarter-turn operation ensures quick open and close cycles, a significant benefit in systems requiring rapid response times.

Key Performance Indicators (KPIs)

- Flow Characteristics: Full bore designs offer minimal resistance to flow, leading to negligible pressure drop across the valve. This preserves system energy and maximizes throughput, translating into significant energy savings over the operational life.

- Leak Tightness: The floating ball design, particularly with resilient soft seats, provides exceptional bubble-tight shut-off. This is crucial for preventing process fluid loss, reducing fugitive emissions, and ensuring environmental compliance.

- Operating Torque: Due to the simple mechanism and low friction between the ball and seats (especially with PTFE), floating ball valves generally exhibit lower operating torque compared to other valve types, which reduces the cost of actuation and simplifies manual operation.

- Temperature and Pressure Range: The Q41F series is designed to operate across a broad spectrum of temperatures and pressures, defined by its ANSI class ratings. Material selection (e.g., specific polymers for seats, various alloys for body) determines its exact operational envelope.

Technical Advantages

- Durability and Longevity: With robust construction, high-quality materials, and precision machining, the Q41F-series floating ball valve offers exceptional durability, minimizing the need for frequent replacement and reducing total cost of ownership (TCO).

- Low Maintenance: The simple design and minimal moving parts contribute to lower maintenance requirements. Wear parts, primarily seats and packing, are relatively easy to replace when maintenance is due.

- Excellent Sealing Capabilities: The pressure-assisted seating mechanism ensures reliable tight shut-off, making it ideal for isolation applications where zero leakage is paramount.

- Corrosion Resistance: When manufactured as a stainless steel ball float valve, the Q41F series offers superior resistance to corrosive media, extending its service life in harsh chemical processes, acidic environments, and saltwater applications. This also applies to the internals and external components of a float operated ball valve used in such environments.

- Versatility: Suitable for a wide range of media including liquids, gases, slurries (with specific seat designs), and viscous fluids. Its adaptability extends to various flow control needs, from simple on/off to more nuanced regulation.

- Energy Efficiency: Full bore configurations reduce friction and turbulence, leading to lower pumping costs and overall system energy savings.

Applicable Industries and Typical Application Scenarios

The versatility of the Q41F-series floating ball valve makes it an indispensable component across numerous industrial sectors:

- Oil and Gas: Used in upstream, midstream, and downstream operations for wellhead control, pipeline isolation, tank farms, and refining processes. Its robust design is critical for handling crude oil, natural gas, refined products, and various process fluids.

- Petrochemical and Chemical Processing: Essential for handling corrosive chemicals, acids, alkalis, and solvents. The choice of material, such as a stainless steel ball float valve, is critical here to ensure long-term integrity against aggressive media.

- Power Generation: Utilized in steam, cooling water, fuel, and chemical treatment systems within power plants (thermal, nuclear, and renewable).

- Water and Wastewater Treatment: For isolation and flow control in municipal water supply, desalination plants, sewage treatment facilities, and industrial water systems. A float operated ball valve or a small ball valve float might find specific niche applications here for level control.

- Mining and Metallurgy: Handling abrasive slurries, process water, and chemical reagents.

- Pharmaceutical and Food & Beverage: Where hygiene and non-contaminating materials are paramount, specialized stainless steel versions are used.

- HVAC and General Industrial Utilities: For managing air, water, and steam lines in commercial buildings and manufacturing facilities.

Case Example: Enhanced Energy Savings in Petrochemical Plants. A major petrochemical client recently integrated our Q41F full-bore floating ball valves into their crude oil refining units. The previous reduced-bore gate valves caused significant pressure drop, leading to increased pumping energy consumption. By replacing these with our Q41F full-bore valves, the client observed a measurable reduction in pipeline pressure loss, directly translating to a 7% decrease in energy consumption for fluid transfer, alongside improved process stability and reduced cavitation. This demonstrates the tangible economic benefits and superior operational efficiency our valves deliver.

Detailed Specifications and Manufacturer Comparison

Q41F-150 300 600LB ANSI Floating Ball Valve: Technical Parameters

The following table outlines the typical technical parameters for our Q41F-series floating ball valve, providing a clear overview of its capabilities and design features:

| Parameter | Description / Value Range |

|---|---|

| Valve Type | Floating Ball Valve (Q41F Series) |

| Design Standard | API 6D, API 608, ASME B16.34 |

| Pressure Class | ANSI Class 150LB, 300LB, 600LB |

| Size Range (DN/NPS) | DN15-DN250 (NPS 1/2" - 10") |

| Connection Type | Flanged (RF, RTJ), Butt Weld, Threaded (NPT, BSP) |

| Body Material | Carbon Steel (WCB, LCB, LCC), Stainless Steel (CF8, CF8M, CF3, CF3M), Alloy Steel (WC6, WC9, C5, C12), Duplex Stainless Steel (CD4MCu, CD3MN) |

| Ball Material | A105+ENP, F304, F316, 17-4PH, F51 (Duplex), A182-F6a, with various coatings |

| Seat Material | PTFE, RPTFE, PEEK, DEVLON, Nylon, PCTFE, Metal-to-Metal |

| Stem Material | F6a, 17-4PH, F304, F316, Duplex, Anti-Blowout Design |

| Operating Temperature | -46°C to +200°C (depending on material & seat) |

| Operating Medium | Water, Oil, Gas, Steam, Acidic, Corrosive fluids |

| Bore Type | Full Bore or Reduced Bore |

| Operation | Lever, Gearbox, Pneumatic Actuator, Electric Actuator |

| Testing Standard | API 598, API 6D, ISO 5208, MSS SP-61 |

Manufacturer Comparison: HBYs Valves vs. Market Competitors

In a competitive landscape, differentiating between valve manufacturers is crucial for procurement and engineering teams. While many manufacturers offer floating ball valves, HBYs Valves distinguishes itself through a commitment to quality, advanced manufacturing, and comprehensive customer support. Below is a comparative overview:

| Feature / Criterion | HBYs Valves (Q41F Series) | Competitor A (General Market) | Competitor B (Premium Market) |

|---|---|---|---|

| Manufacturing Process | Precision CNC Machining, Forging/Casting, ISO 9001 certified, rigorous NDE. | Standard casting/machining, varying QC, potential reliance on third-party components. | Advanced machining, robust QC, often higher specialization. |

| Material Traceability | Full MTRs (Material Test Reports) available for all critical components, end-to-end traceability. | Partial or limited traceability, may vary by batch. | Comprehensive MTRs, high traceability standards. |

| Testing & Certifications | 100% Hydrostatic & Pneumatic testing (API 598), API 6D, ISO 9001, CE, ATEX (as required). Fugitive emissions testing available. | Basic hydrostatic testing, limited adherence to international standards for all batches. | Extensive testing, often with third-party verification, wide range of certifications. |

| Customization Capabilities | Strong engineering team for tailor-made solutions (materials, coatings, end connections, actuation), including specialized small ball valve float designs or float operated ball valve adaptations. | Limited customization, primarily standard configurations. | Good customization, but often with higher lead times and costs for bespoke solutions. |

| Delivery Lead Times | Optimized production & supply chain for competitive lead times (e.g., 4-8 weeks for standard orders, project-based for custom). | Can be unpredictable, depending on stock levels and production backlog. | Generally longer lead times for quality control and customization. |

| After-Sales Support & Warranty | Comprehensive technical support, readily available spare parts, clear warranty terms (e.g., 18 months from shipment or 12 months from installation). | Basic support, spare parts availability may be an issue. | Strong after-sales, but possibly at a higher service cost. |

| Price-Performance Ratio | Exceptional balance, offering premium quality and performance at a highly competitive price point, optimizing TCO. | Lower initial cost but higher long-term risks due to potential reliability issues. | Premium pricing, often justified for niche, ultra-critical applications. |

HBYs Valves' commitment to stringent quality control, adherence to global standards, and customer-centric approach positions its Q41F-series floating ball valve as a superior choice for industrial applications where reliability and performance are non-negotiable.

Custom Solutions, Quality Assurance, and Unwavering Support

In the realm of industrial valves, a one-size-fits-all approach rarely suffices. Complex processes often require specialized configurations, materials, and testing protocols. HBYs Valves prides itself on offering not just standard Q41F-series floating ball valves, but also bespoke solutions meticulously engineered to meet the unique challenges of specific applications.

Tailored Customization and Expert Engineering Support

Our dedicated team of engineers collaborates closely with clients to understand their precise operational parameters, media characteristics, and regulatory requirements. This consultative approach allows us to deliver customized floating ball valve solutions that optimize performance and minimize risks. Customization options include:

- Specialized Materials: Beyond standard carbon and stainless steels, we offer valves in exotic alloys such as Inconel, Monel, Hastelloy, or super duplex stainless steel for highly corrosive or high-temperature applications. This ensures robust performance, even for a stainless steel ball float valve in extreme environments.

- Specific Coatings and Linings: For abrasive slurries or highly adhesive media, specialized coatings (e.g., hard chrome, tungsten carbide) or internal linings can be applied to enhance wear resistance and prevent sticking.

- End Connections: While standard flanged connections are common, we can provide valves with butt-weld ends for severe service, socket weld, or specialized threaded connections to integrate seamlessly into existing pipeline designs.

- Actuation and Automation: Integration with pneumatic, hydraulic, or electric actuators for automated control, including smart valve positioning and feedback systems. This also encompasses specialized float operated ball valve systems for level control.

- Low Emissions Design: Implementing enhanced stem packing arrangements (e.g., live-loaded packing, bellows seals) and rigorous testing to comply with international fugitive emissions standards (ISO 15848-1, API 622).

- Cryogenic or High-Temperature Service: Design modifications, including extended bonnets and specialized packing, to handle extreme temperatures effectively.

- Specific Instrumentation: Integration of limit switches, positioners, and other accessories for precise monitoring and control.

- Small Ball Valve Float: For applications requiring compact and precise flow control, we can engineer small ball valve float solutions tailored to specific space constraints and flow rates.

Unwavering Quality Control and Certification Adherence

Quality is the cornerstone of HBYs Valves' operations. Our manufacturing facilities operate under a stringent ISO 9001 certified quality management system, ensuring that every stage, from raw material inspection to final product testing, adheres to the highest standards. Beyond standard industry benchmarks, we also comply with critical certifications relevant to various global markets and specific industries:

- API 6D and API 608: Adherence to American Petroleum Institute standards for pipeline valves, ensuring robust design and testing for the oil and gas sector.

- CE Marking: Compliance with European Union safety, health, and environmental protection requirements for products sold within the EEA.

- ATEX Directive: For valves operating in potentially explosive atmospheres, guaranteeing safety compliance.

- SIL Certification: Safety Integrity Level assessment for critical applications requiring specific levels of safety performance.

- Fugitive Emissions Standards (e.g., ISO 15848-1, API 622): Ensuring minimal leakage for environmental protection and compliance with strict air quality regulations.

Our in-house testing capabilities include comprehensive hydrostatic and pneumatic pressure tests, non-destructive examinations (RT, UT, MT, PT), functional tests, and specialized cryogenic or high-temperature tests when required. Each valve comes with complete documentation, including Material Test Reports (MTRs), pressure test certificates, and compliance declarations, providing full traceability and assurance.

Streamlined Delivery, Comprehensive Warranty, and Responsive Customer Support

Understanding the criticality of project timelines, HBYs Valves has optimized its production and logistics processes to ensure efficient delivery. For standard Q41F floating ball valve orders, lead times are typically 4-8 weeks, while custom or large-scale projects are managed with detailed project plans to meet client schedules. Our global logistics network ensures prompt and secure delivery worldwide.

We stand behind the quality of our products with a comprehensive warranty, typically covering defects in material and workmanship for a period of 18 months from the date of shipment or 12 months from installation, whichever comes first. This commitment reflects our confidence in the durability and reliability of our floating ball valve products.

Our customer support extends beyond the sale. A team of experienced technical professionals is available to provide:

- Installation and Commissioning Guidance: Ensuring proper setup for optimal performance.

- Troubleshooting and Maintenance Support: Expert advice to resolve operational issues and extend valve lifespan.

- Spare Parts Availability: Readily accessible genuine spare parts to minimize downtime.

- Training: On-site or remote training sessions for client's operational and maintenance personnel.

Client Success Story: Minimizing Downtime in a Chemical Plant. A chemical manufacturing client experienced frequent valve failures with a competitor's products due to media crystallization. Upon consultation, HBYs Valves recommended a custom Q41F floating ball valve with specialized internal coatings and a heating jacket design. Our engineering team provided detailed installation instructions and follow-up support. This bespoke solution not only eliminated crystallization issues but also reduced valve maintenance frequency by 80%, significantly cutting downtime and saving estimated operational costs of over $150,000 annually. This case highlights our commitment to solving complex problems with tailored, reliable solutions.

Frequently Asked Questions (FAQs) about Floating Ball Valves

Q1: What is the primary difference between a floating ball valve and a trunnion-mounted ball valve?

A floating ball valve relies on the upstream fluid pressure to push the ball against the downstream seat for sealing. This design is typically used for smaller to medium sizes and lower to medium pressure classes (e.g., ANSI Class 150-600LB). A trunnion-mounted ball valve has a ball supported by trunnions (shafts) at the top and bottom, reducing the friction and torque required for operation, making it suitable for larger sizes and higher pressures (e.g., ANSI Class 900LB and above). The trunnion design prevents over-compression of the seat, extending seat life in high-cycle or abrasive applications.

Q2: How do I select the right material for my floating ball valve?

Material selection is critical and depends on several factors: the type of fluid (corrosive, abrasive, clean), operating temperature, and pressure. For general service, carbon steel (WCB) is common. For corrosive media, a stainless steel ball float valve (304, 316, or specialized alloys like Duplex) is recommended. For extreme temperatures, specific alloy steels are used. Seat materials (PTFE, PEEK, metal) are chosen based on temperature, chemical compatibility, and desired leak tightness. Always consult the manufacturer's material compatibility charts and industry standards (e.g., NACE for sour service).

Q3: What are the main advantages of a full bore Q41F floating ball valve over a reduced bore?

A full bore floating ball valve has an internal bore diameter equal to the connecting pipeline, resulting in minimal pressure drop and unimpeded flow. This makes it ideal for applications requiring pigging (pipeline inspection gauges) or where maintaining maximum flow and reducing energy consumption is crucial. Reduced bore valves, while more compact and cost-effective, introduce a slight flow restriction, making them suitable for general on/off service where pressure drop is less of a concern.

Q4: Can a floating ball valve be used for throttling or flow control?

While a floating ball valve is primarily designed for on/off (isolation) service, it can be used for limited throttling. However, prolonged throttling can lead to increased wear on the seats and ball due to high velocity flow impacting a partially open valve, potentially causing cavitation or erosion. For precise and continuous flow control, specialized control valves (e.g., globe valves, V-port ball valves) are generally preferred due to their optimized design for throttling applications. If a small ball valve float is used for limited flow, it's essential to consider the impact on longevity.

Q5: What maintenance is required for a floating ball valve?

Floating ball valves are generally low-maintenance. Key maintenance activities include periodic inspection for external leakage, especially around the stem packing. If leakage occurs, packing glands may need to be tightened or packing replaced. For soft-seated valves, seats are wear components and may require replacement after extensive cycles or exposure to harsh conditions. Regular lubrication of the stem and actuator (if applicable) is recommended to ensure smooth operation. Adherence to manufacturer's recommendations and regular operational cycling can significantly extend the valve's service life.

Q6: What is a float operated ball valve and where is it typically used?

A float operated ball valve is a specialized type of ball valve where the opening and closing mechanism is actuated by a float, typically in a tank or reservoir. As the fluid level rises or falls, the float moves, which in turn operates the ball valve to control the inflow or outflow of fluid, maintaining a desired level. These are commonly used in water tanks, cooling towers, and industrial process tanks for automatic liquid level control, preventing overflow or ensuring a minimum level is maintained. They are a form of automatic control valve specifically designed for level management.

Conclusion: Choosing HBYs Valves for Your Critical Applications

The selection of an appropriate valve is paramount to the safety, efficiency, and long-term profitability of any industrial operation. The Q41F-150 300 600LB ANSI floating ball valve from HBYs Valves stands as a testament to engineering excellence, designed to deliver unparalleled performance and reliability across a multitude of challenging applications. From its meticulously controlled manufacturing process, leveraging advanced CNC machining and robust testing protocols, to its versatility in handling diverse media under varying pressure and temperature conditions, this valve consistently exceeds industry expectations.

Our commitment extends beyond product delivery. With a profound understanding of the complex needs of B2B clients, we offer comprehensive technical support, flexible customization options—whether for a standard floating ball valve or a specialized small ball valve float—and an unwavering dedication to after-sales service. Our stringent adherence to international standards like API 6D, ISO 9001, and our capability to provide full material traceability and certifications, underscore our position as a trusted partner. Choosing HBYs Valves means investing in solutions that reduce operational costs, enhance safety, minimize environmental impact, and provide long-term peace of mind. Partner with us to ensure your fluid control systems operate with peak efficiency and unwavering dependability.

References

- American Petroleum Institute. API 6D: Specification for Pipeline and Piping Valves.

- American Society of Mechanical Engineers. ASME B16.34: Valves – Flanged, Threaded, and Welding End.

- International Organization for Standardization. ISO 9001: Quality management systems – Requirements.

- International Organization for Standardization. ISO 15848-1: Industrial valves – Measurement, test and qualification procedures for fugitive emissions – Part 1: Classification system and qualification procedures for type tests.

- Manufacturers Standardization Society of the Valve and Fittings Industry. MSS SP-61: Pressure Testing of Valves.

- Valve Manufacturers Association of America (VMA). Valve Magazine.

- European Committee for Standardization. EN 13445-3: Unfired pressure vessels - Part 3: Design.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025