Feb . 12, 2025 01:47

Back to list

ss globe valve

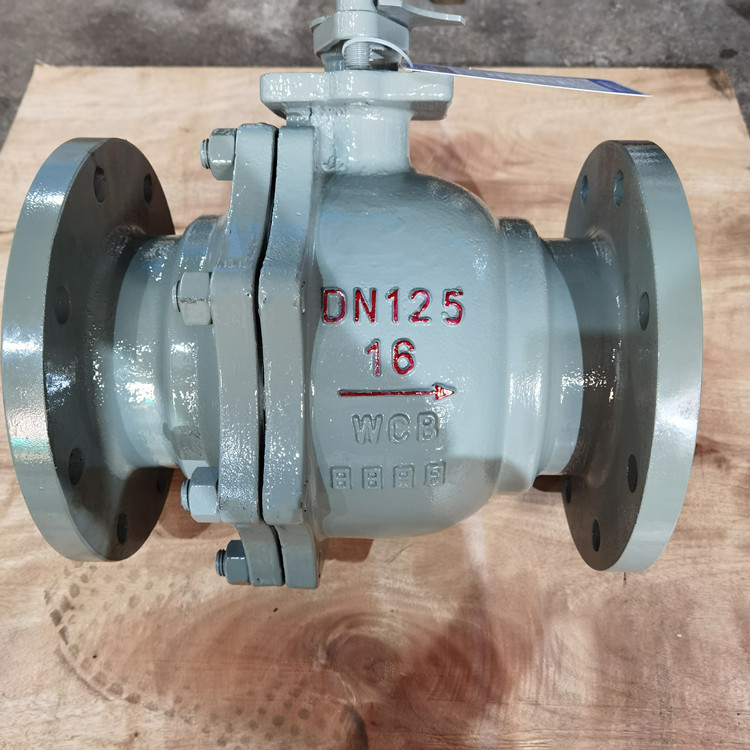

Globe valves, particularly those rated at PN16, play a pivotal role in industrial and domestic applications by offering efficient flow control. Their robust design and operational efficiency make them a critical component in various piping systems. Professionals seeking reliable and durable options will find globe valves PN16 to be a suitable fit due to their versatility and precision.

Professional installation and maintenance are crucial to ensure that these valves function correctly over time. Expertise in installation involves understanding the pipeline's dynamics and ensuring the valve's alignment with the flow direction to minimize pressure drop and energy loss. Regular maintenance checks, including lubrication and inspection for wear or damage, can prolong the valve’s service life. It is advisable to partner with certified specialists for these tasks to guarantee reliability and safety. The authoritative recommendations for globe valve PN16 point towards considering both operational conditions and cost-effectiveness. While initial investment might be higher compared to alternative valves, their durable nature and low maintenance needs outweigh upfront costs in the long run. Furthermore, the versatility of these valves, being suitable for both throttling and isolation purposes, makes them a cost-efficient choice for complex systems requiring consistent performance without frequent replacements. Trustworthiness extends to selecting verified suppliers and manufacturers known for their quality assurance processes. Equally important is acquiring valves with proper certifications that comply with international standards such as ISO, thus ensuring that your system is not only efficient but also safe and compliant with regulatory requirements. In conclusion, globe valves PN16 are a cornerstone of efficient flow management within various industries. They combine durability, precision, and reliability, meeting the critical needs of complex systems that demand rigorous performance standards. By investing in high-quality globe valves and ensuring proper installation and maintenance, businesses can effectively enhance system integrity while mitigating operational risks, thus ensuring long-term success and safety in their operations.

Professional installation and maintenance are crucial to ensure that these valves function correctly over time. Expertise in installation involves understanding the pipeline's dynamics and ensuring the valve's alignment with the flow direction to minimize pressure drop and energy loss. Regular maintenance checks, including lubrication and inspection for wear or damage, can prolong the valve’s service life. It is advisable to partner with certified specialists for these tasks to guarantee reliability and safety. The authoritative recommendations for globe valve PN16 point towards considering both operational conditions and cost-effectiveness. While initial investment might be higher compared to alternative valves, their durable nature and low maintenance needs outweigh upfront costs in the long run. Furthermore, the versatility of these valves, being suitable for both throttling and isolation purposes, makes them a cost-efficient choice for complex systems requiring consistent performance without frequent replacements. Trustworthiness extends to selecting verified suppliers and manufacturers known for their quality assurance processes. Equally important is acquiring valves with proper certifications that comply with international standards such as ISO, thus ensuring that your system is not only efficient but also safe and compliant with regulatory requirements. In conclusion, globe valves PN16 are a cornerstone of efficient flow management within various industries. They combine durability, precision, and reliability, meeting the critical needs of complex systems that demand rigorous performance standards. By investing in high-quality globe valves and ensuring proper installation and maintenance, businesses can effectively enhance system integrity while mitigating operational risks, thus ensuring long-term success and safety in their operations.

Next:

Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025