PARAMETER EKPERE:

| ANSI Pipe Fittings Series Main production materials | |||||

| Material name | |||||

| ASTM A105, 20 #, Q235, 16Mn | |||||

| ASTM A182 F304, F316, 316L, 321 |

| Flange type | Thickness range | Caliber range | Implementation standards | ||||

| elbow | SCH10-SCH160 | 1/2 "-48" | ANSI B16.9 | ||||

| Tee | 1 1/2 "* 1 1/2" -24 "* 18" | ||||||

| Reducer | 1 "* 3/4" -24 "* 22" | ||||||

| Tube cap | 1/2 "-48" |

| ANSI pipe fitting dimensions and connection dimensions | |||||||

| Long radius elbow | |||||||

| Dayameta aha aha (inches) |

Outer diameter | Thickness (mm) | |||||

| D | SCH10 | SCH30 | STD | SCH40 | XS | SCH80 | |

| 1/2 | 21.3 | 2.11 | 2.41 | 2.77 | 2.77 | 3.73 | 3.73 |

| 3/4 | 26.7 | 2.11 | 2.41 | 2.87 | 2.87 | 3.91 | 3.91 |

| 1 | 33.4 | 2.77 | 2.9 | 3.38 | 3.38 | 4.55 | 4.55 |

| 1 1/4 | 42.2 | 2.77 | 2.97 | 3.56 | 3.56 | 4.85 | 4.85 |

| 1 1/2 | 48.3 | 2.77 | 3.18 | 3.68 | 3.68 | 5.08 | 5.08 |

| 2 | 60.3 | 2.77 | 3.18 | 3.91 | 3.91 | 5.54 | 5.54 |

| 2 1/2 | 73 | 3.05 | 4.78 | 5.16 | 5.16 | 7.01 | 7.01 |

| 3 | 88.9 | 3.05 | 4.78 | 5.49 | 5.49 | 7.62 | 7.62 |

| 3 1/2 | 101.6 | 3.05 | 4.78 | 5.74 | 5.74 | 8.08 | 8.08 |

| 4 | 114.3 | 3.05 | 4.78 | 6.02 | 6.02 | 8.56 | 8.56 |

| 5 | 141.3 | 3.4 | - | 6.55 | 6.55 | 9.53 | 9.53 |

| 6 | 168.3 | 3.4 | - | 7.11 | 7.11 | 10.97 | 10.97 |

| 8 | 219.1 | 3.76 | 7.04 | 8.18 | 8.18 | 12.7 | 12.7 |

| 10 | 273.1 | 4.19 | 7.8 | 9.27 | 9.27 | 12.7 | 15.09 |

| Tee | ||||||

| Dayameta aha aha (inches) |

Outer diameter | STD | SCH40 | |||

| D1 | D2 | t1 | t2 | t1 | t2 | |

| 1 1/2 * 1 1/2 | 48.3 | 48.3 | 2.77 | 2.77 | 2.77 | 2.77 |

| 2 * 3/4 | 60.3 | 26.7 | 3.91 | 2.87 | 3.91 | 2.87 |

| *1 | - | 33.4 | - | 3.32 | - | 3.38 |

| * 1 1/4 | - | 42.2 | - | 3.56 | - | 3.56 |

| * 1 1/2 | - | 48.3 | - | 3.68 | - | 3.68 |

| *2 | - | 60.3 | - | 3.91 | - | 3.91 |

| Tube cap | ||||||

| Dayameta aha aha (inches) |

Outside diameter D | E height | Limit thickness | Height E1 | t | |

| Hidemura | mm | SCH40 | ||||

| 1/2 | 0.84 | 21.34 | 25.4 | 4.57 | 25.4 | 0.109 |

| 3/4 | 1.05 | 26.67 | 25.4 | 3.81 | 25.4 | 0.133 |

| 1 | 1.315 | 33.4 | 38.1 | 4.57 | 38.1 | 0.133 |

| 1 1/4 | 1.66 | 42.2 | 38.1 | 4.83 | 38.1 | 0.14 |

| 1 1/2 | 1.9 | 48.2 | 38.1 | 5.08 | 38.1 | 0.145 |

| 2 | 2.375 | 48.3 | 38.1 | 5.59 | 44.5 | 0.154 |

| Reducer | ||||||

| Dayameta aha aha (inches) |

Outer diameter | STD | SCH40 | |||

| D1 | D2 | t1 | t2 | t1 | t2 | |

| 1 * 3/4 | 33.4 | 26.7 | 3.38 | 2.87 | 3.38 | 2.87 |

| 1 1/2 * 3/4 | 48.3 | 26.7 | 3.68 | 2.87 | 3.68 | 2.87 |

| *1 | - | 33.4 | - | 3.38 | - | 3.38 |

| * 1 1/4 | - | 42.2 | - | 3.56 | - | 3.56 |

| 2 * 1 | 60.3 | 33.4 | 3.91 | 3.38 | 3.91 | 3.38 |

| * 1 1/4 | - | 42.2 | - | 3.56 | - | 3.56 |

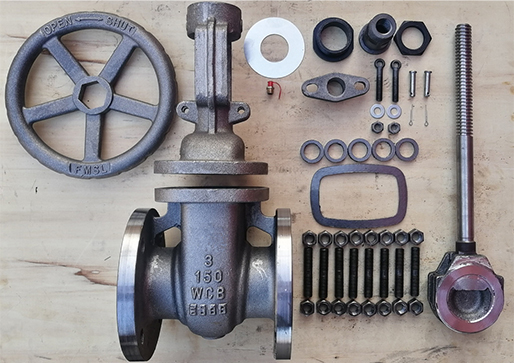

PRODUCT ADVANTAGES:

1.We nwere ájá ma ọ bụ nkenke nkedo technology, Ya mere, anyị nwere ike dị ka gị ịbịaru imewe na mmepụta.

2.Customers 'logo dị na nkedo na valvụ ahụ.

3. All anyị nkedo na usoro iwe tupu nhazi.

4. Use the CNC lathe during whole process.

5. The disc sealing surface use plasma welding machine welding

6. Every valve must be tested before delivery from the factory, only qualified onescanbe shipped.

7.The ụdị valvụ anyị na-ejikarị osisi ikpe na ngwugwu, Anyị nwekwara ike dị ka

arịrịọ ndị ahịa kpọmkwem.

COMPANY ADVANTAGES:

-

1.We bụ emeputa Ebe ọ bụ na 1992.

1.We bụ emeputa Ebe ọ bụ na 1992. -

2.CE,API,ISO kwadoro.

2.CE,API,ISO kwadoro. -

3.Nfefe ngwa ngwa.

3.Nfefe ngwa ngwa. -

4. Low price na elu mma.

4. Low price na elu mma. -

5.Professional ọrụ Team!

5.Professional ọrụ Team!

Dee ozi gị ebe a ziga anyị ya

Ejikọtara ya products

Ejikọtara ya news