pipe valve and fitting supplier

Understanding the Essentials of Pipe, Valve, and Fitting Suppliers

In numerous industries, from construction to oil and gas, the role of pipe, valve, and fitting suppliers is pivotal. These components play fundamental roles in the management of fluid transfer and control systems. Understanding their significance and the nature of these suppliers can greatly benefit manufacturers, contractors, and engineers who rely on these essential products for their operations.

The Importance of Pipes, Valves, and Fittings

Pipes are essential for transporting liquids and gases from one location to another. They come in various materials, including PVC, steel, and copper, each suited for specific applications based on factors like pressure, temperature, and the type of fluid being conveyed.

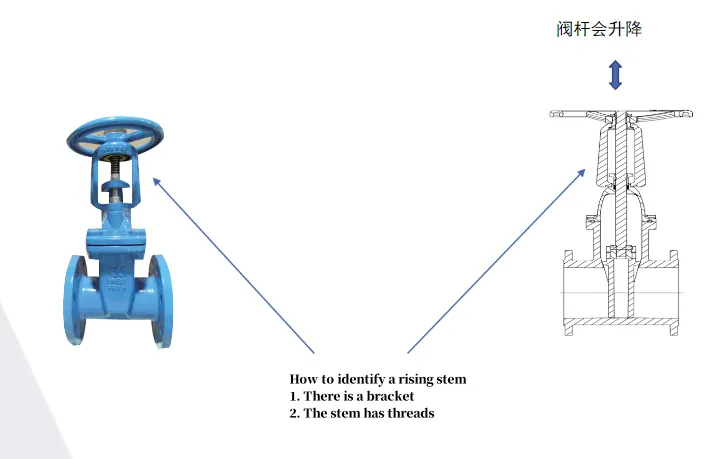

Valves are crucial for controlling the flow of fluids within these pipes. They help in regulating pressure and protecting systems from damage during unexpected surges. Different types of valves, such as gate valves, ball valves, and check valves, all serve unique purposes and thus cater to varying operational needs.

Fittings, on the other hand, are the connectors that hold piping systems together. They come in numerous shapes and sizes and are essential for ensuring a sealed and functional system. Like pipes and valves, fittings are manufactured from diverse materials, impacting their durability and compatibility.

The Role of Suppliers

Suppliers specializing in pipes, valves, and fittings provide the infrastructure that enables businesses to acquire high-quality products necessary for their operations. An effective supplier understands the intricacies of these components and maintains extensive inventories to meet various customer demands.

One of the primary responsibilities of these suppliers is to source their products from reputable manufacturers to ensure that they meet industry standards. This importance is underscored in sectors like oil and gas, where safety is paramount. Quality components can prevent leaks and operational failures that could result in expensive downtime or even catastrophic accidents.

Additionally, suppliers offer critical support services, including inventory management and logistics. They offer tailored solutions, ensuring that clients receive the right products at the right time. This is particularly essential for projects with strict timelines and budget constraints. A reliable supplier can help manage supply chain issues that may arise, significantly improving a company's operational efficiency.

pipe valve and fitting supplier

Selecting the Right Supplier

When choosing a pipe, valve, and fitting supplier, several factors should be considered to ensure you are partnering with a reliable source.

1. Quality Assurance Always look for suppliers who can provide certifications and test results for their products. This information reflects the supplier's commitment to quality and safety.

2. Product Range A supplier that offers a diverse range of products can better meet your requirements. This means that as projects evolve or new technology emerges, you have a source that can supply the latest innovations.

3. Customer Service The best suppliers prioritize customer satisfaction. Look for those who offer technical assistance, can answer your queries, and provide valuable insights into product selection.

4. Delivery and Logistics Timeliness is crucial in industries where delays can lead to significant financial losses. Assess a supplier's delivery performance to ensure they meet your project schedules.

5. Pricing Competitive pricing is essential, but it shouldn't come at the expense of quality. Evaluate quotes from different suppliers while considering the quality of the products offered.

Conclusion

In conclusion, pipe, valve, and fitting suppliers are indispensable in a wide range of industries. Their role as a bridge that connects manufacturers and end-users cannot be overstated. By ensuring the availability of high-quality products, suppliers contribute significantly to the smooth operation of projects and maintenance regimes.

Whether it’s for a small construction job or a large-scale industrial operation, understanding the critical functions that these suppliers fulfill can lead to informed decisions, ensuring that your projects proceed without a hitch. By selecting the right supplier, businesses can enhance their operational efficiency, safeguard their systems, and ultimately ensure the success of their endeavors in a competitive marketplace.

-

3-types-of-check-valves-maintenance-tipsNewsAug.23,2025

-

ball-valves-types-with-trunnion-mounted-designNewsAug.23,2025

-

butterfly-valve-company-production-capabilitiesNewsAug.23,2025

-

fisher-globe-valve-technical-specificationsNewsAug.23,2025

-

types-of-gaskets-for-flanges-selection-guideNewsAug.23,2025

-

wedge-gate-valve-suppliers-quality-standardsNewsAug.23,2025

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025