Gen . 15, 2025 00:48

Back to list

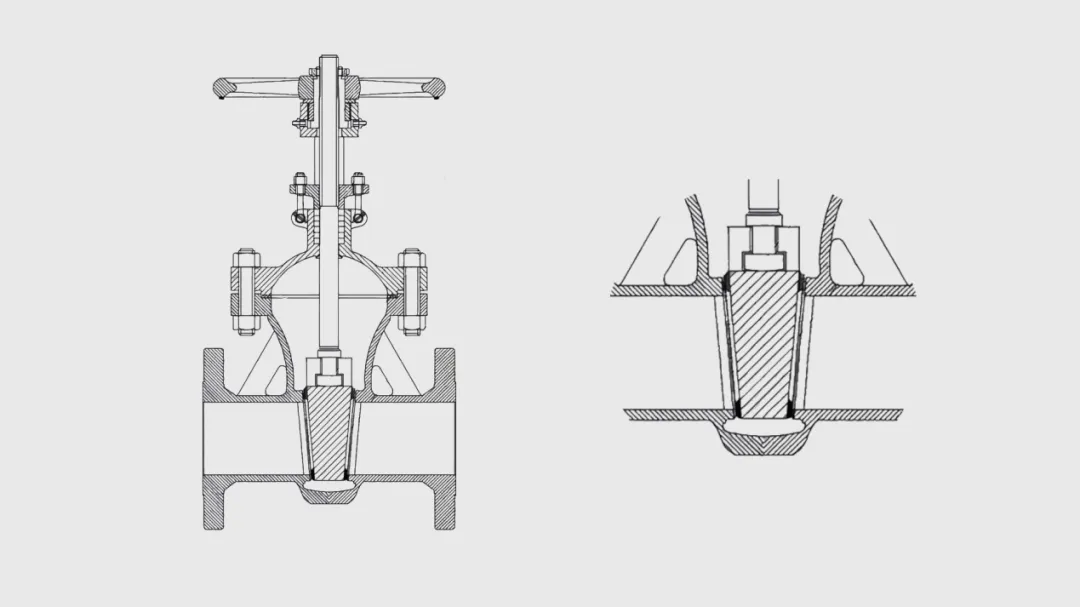

flap valve

Flap valves play a crucial role in a wide range of industries due to their unique ability to control fluid dynamics with precision and reliability. Known for their effective one-way mechanism, these valves have become indispensable in sectors such as water management, wastewater treatment, and various manufacturing processes.

An engineer, having worked on various industrial installations, recounts a scenario where a flap valve prevented a potentially catastrophic overflow in a chemical plant. By halting backflow during unexpected pump failures, the flap valve allowed for swift corrective measures, showcasing its reliability in critical situations. Testimonials such as these underscore the life-saving potential of these components in high-stakes environments. The authority of internationally recognized standards such as the American Society of Mechanical Engineers (ASME) ensures that flap valves comply with rigorous specifications, further solidifying their trustworthiness. Products adhering to these standards are deemed highly reliable and are thus preferred by industries around the world. Such endorsements are a testament to the credibility and efficiency that flap valves bring to large-scale operations. When considering the purchase of flap valves, prospective buyers are encouraged to consult with certified suppliers who offer comprehensive technical support and aftersales service. This ensures the selection of appropriate valve sizes and materials suited to specific industrial needs. Partnerships with reputable manufacturers also guarantee product authenticity and adherence to quality standards, significantly enhancing operational safety and efficiency. Flap valves represent a synergy of experience, expertise, authoritativeness, and trustworthiness that few other products can match. Their enduring presence across multiple sectors is a testament to their indispensable nature and the peace of mind they provide to engineers and operators aiming for seamless operations. The continuous evolution of design and functionality further ensures that flap valves will remain a cornerstone of fluid management systems well into the future.

An engineer, having worked on various industrial installations, recounts a scenario where a flap valve prevented a potentially catastrophic overflow in a chemical plant. By halting backflow during unexpected pump failures, the flap valve allowed for swift corrective measures, showcasing its reliability in critical situations. Testimonials such as these underscore the life-saving potential of these components in high-stakes environments. The authority of internationally recognized standards such as the American Society of Mechanical Engineers (ASME) ensures that flap valves comply with rigorous specifications, further solidifying their trustworthiness. Products adhering to these standards are deemed highly reliable and are thus preferred by industries around the world. Such endorsements are a testament to the credibility and efficiency that flap valves bring to large-scale operations. When considering the purchase of flap valves, prospective buyers are encouraged to consult with certified suppliers who offer comprehensive technical support and aftersales service. This ensures the selection of appropriate valve sizes and materials suited to specific industrial needs. Partnerships with reputable manufacturers also guarantee product authenticity and adherence to quality standards, significantly enhancing operational safety and efficiency. Flap valves represent a synergy of experience, expertise, authoritativeness, and trustworthiness that few other products can match. Their enduring presence across multiple sectors is a testament to their indispensable nature and the peace of mind they provide to engineers and operators aiming for seamless operations. The continuous evolution of design and functionality further ensures that flap valves will remain a cornerstone of fluid management systems well into the future.

Next:

Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025