Types of Manual Valves and Their Applications in Fluid Control Systems

Understanding Manual Valve Types

Manual valves are essential components in various industrial applications, playing a crucial role in regulating fluid flow and pressure within piping systems. These valves are operated manually, allowing technicians to precisely control the opening and closing of fluid passages. This article provides an overview of the most common manual valve types, their characteristics, and applications.

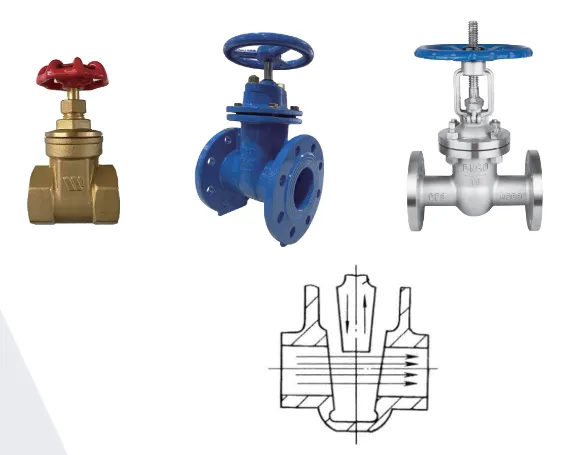

1. Gate Valve

The gate valve is one of the most widely used manual valves known for its ability to start or stop fluid flow with minimal resistance. It features a gate or wedge that slides into the flow path, providing a straight-through passage. Gate valves are primarily used in applications where low-pressure drops are critical, such as in water supply systems and oil pipelines. However, they are not suitable for throttling applications, as partially open gates can cause vibration and damage.

2. Globe Valve

Globe valves are designed for precise flow regulation, making them ideal for throttling applications. They consist of a spherical body and an internal baffle that divides the flow stream. The valve's disc can be raised or lowered to control flow effectively. Globe valves are commonly used in heating systems, water supply systems, and chemical processing, where precise flow control is vital.

3. Ball Valve

manual valve types

Ball valves offer a quick and effective means of controlling flow using a spherical disc (the ball) with a hole through its center. When the ball is rotated, the flow path opens or closes swiftly. Ball valves provide excellent sealing capabilities and are excellent for on/off control. They are utilized in various applications, including gas and water lines, as well as in food processing and pharmaceutical industries.

4. Butterfly Valve

Butterfly valves consist of a rotating disc or plate that pivots within the valve body. When the disc is turned, it opens or closes the flow passage. These valves are lightweight and require minimal space, making them suitable for services where space is a concern. Common applications include HVAC systems, water supply treatment, and chemical storage.

5. Plug Valve

Plug valves operate similarly to stopcocks, with a cylindrical or tapered plug that can be rotated to open or close the flow passage. They offer minimal resistance and are typically used in situations requiring quick shut-off. Their robust design makes them ideal for applications involving viscous fluids, such as in the oil and gas industry.

Conclusion

In summary, manual valves play a vital role across various industries, each type offering distinct advantages based on specific application needs. Understanding the characteristics and functions of gate, globe, ball, butterfly, and plug valves is essential for anyone involved in fluid management and control. Proper selection and maintenance of these valves can enhance system efficiency and prolong equipment life, ensuring optimal performance in industrial operations.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025