Foot Valve Design and Functionality for Efficient Fluid Control Systems

Understanding Foot Valves The Key Component in Fluid Systems

In the world of fluid management and systems engineering, certain components play a vital role in ensuring the efficiency and reliability of operations. One such component is the foot valve, often overlooked but critical in various applications, from irrigation systems to industrial processes. This article delves into the importance and functionality of foot valves, particularly focusing on the concept of foot valve 1.202 and its relevance in today's fluid systems.

What is a Foot Valve?

A foot valve is a type of check valve installed at the bottom of a suction line in a fluid system. Its primary function is to prevent backflow when the pump is not in operation. Essentially, it acts as a one-way gate, allowing fluid to flow into the pump while preventing it from flowing back out. This is crucial for maintaining the priming of the pump and ensuring that it can operate efficiently whenever needed.

The Design and Functionality of Foot Valves

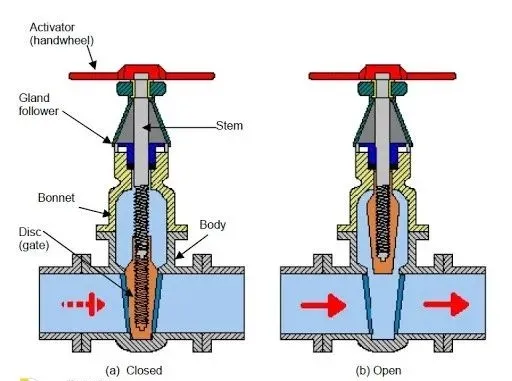

Typically made from durable materials such as stainless steel, PVC, or brass, foot valves are designed to withstand various pressures and environmental conditions. The key components of a foot valve include a valve body, a strainer, and a disc or flap that seals the valve. When the pump operates, the disc opens under pressure, allowing fluid to flow into the system. Once the pump is turned off, the disc closes, creating a seal that prevents backflow.

Foot valves can come in various sizes and specifications, with foot valve 1.202 representing a specific model characterized by its design, pressure rating, and compatibility with various pumps. The number often indicates the diameter or flow capacity, although exact specifications may vary by manufacturer.

Applications of Foot Valves

Foot valves find their applications in a plethora of industries. In agriculture, for example, they are crucial for irrigation systems where they help manage water flow efficiently. A properly functioning foot valve ensures that water remains in the suction line, allowing pumps to prime quickly and reducing the overall energy required for pumping operations.

In industrial applications, foot valves are employed in water treatment plants, chemical processing, and various manufacturing processes. They help maintain fluid levels and prevent contamination by creating a barrier against backflow. This is particularly important in systems where the integrity of the fluid being pumped is critical.

foot valve 1 2

Advantages of Using Foot Valves

1. Prevention of Backflow The primary advantage of foot valves is their ability to prevent backflow, which can cause pumps to lose prime and lead to air locks or system failures. This is essential for ensuring continuous operation.

2. Efficiency By maintaining the fluid level in the suction line, foot valves improve the efficiency of pumping systems. This can lead to reduced energy costs and extended pump life.

3. Versatility Foot valves can be used in various applications, making them a versatile choice for fluid management across different industries.

4. Ease of Maintenance Most foot valves are designed to be easily accessible for cleaning and maintenance, ensuring they can function optimally over time.

Choosing the Right Foot Valve

When selecting a foot valve, it is crucial to consider several factors, including the fluid type, temperature, pressure ratings, and the specific application. Models like foot valve 1.202 may offer unique features suitable for particular environments. Engaging with a knowledgeable supplier or manufacturer can aid in selecting the appropriate foot valve for specific needs.

Conclusion

Foot valves, such as the foot valve 1.202, are integral components of fluid systems, ensuring efficient operation by preventing backflow and maintaining pump priming. Their varied applications across agricultural and industrial sectors underscore their importance in modern fluid management. Understanding the functionality, benefits, and selection criteria for foot valves can help enhance system performance and reliability. As industries continue to evolve, the role of components like foot valves remains crucial in facilitating efficient fluid transport solutions.

-

3 types of check valves maintenance tipsNewsAug.23,2025

-

Ball valves types with trunnion mounted designNewsAug.23,2025

-

Butterfly valve company production capabilitiesNewsAug.23,2025

-

Fisher globe valve technical specificationsNewsAug.23,2025

-

Types of gaskets for flanges selection guideNewsAug.23,2025

-

Wedge gate valve suppliers quality standardsNewsAug.23,2025

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025