High-Quality Pipe Valve Fittings Manufacturer for Reliable Industrial Applications and Custom Solutions

The Importance of Pipe Valve Fitting Factories in Modern Industry

In today's fast-paced industrial landscape, the significance of pipe valve fitting factories cannot be overstated. These facilities play a crucial role in manufacturing essential components that ensure the smooth operation of various systems across multiple sectors, including water supply, oil and gas, chemicals, and manufacturing processes. This article delves into the functions of pipe valve fitting factories, the types of products they produce, and their impact on the economy and industrial efficiency.

Understanding Pipe Valve Fittings

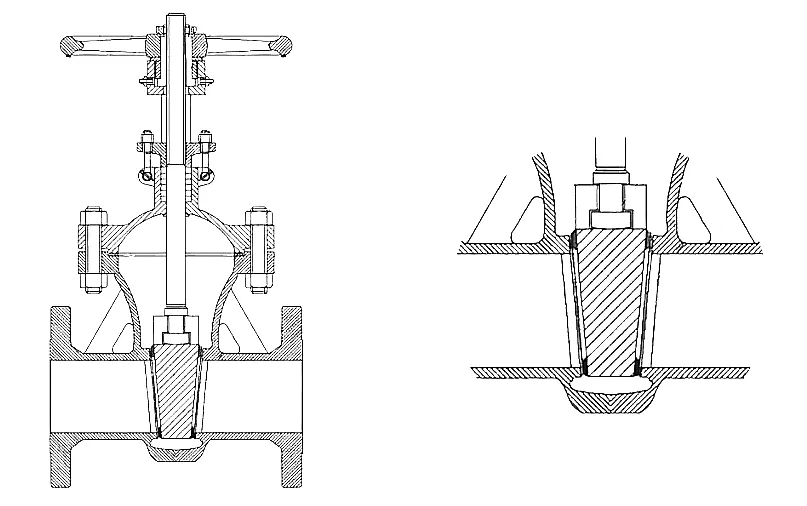

Pipe valve fittings are essential mechanical components used to control, direct, and regulate fluid flow within piping systems. They include a wide array of products, such as valves, connectors, flanges, and fittings, which are critically important in ensuring the safe and efficient transport of gases and liquids. Valves control the flow and pressure of substances, while fittings are used to connect distinct sections of piping, allowing for flexibility and adaptability in system design.

Manufacturing Process of Pipe Valve Fittings

The manufacturing process of pipe valve fittings typically involves several steps, including design, material selection, machining, assembly, and quality control. Factories utilize advanced technologies such as computer-aided design (CAD) and computer numerical control (CNC) machining to create high-precision components that meet stringent industry standards. Materials commonly used in the production of these fittings include stainless steel, brass, plastic, and other alloys, chosen for their durability, corrosion resistance, and adaptability to various fluids.

Quality control is paramount in this industry. Pipe valve fitting factories must adhere to various international and local standards, such as ISO and ASTM, to ensure the safety and reliability of their products. Rigorous testing, including pressure tests, leak tests, and material inspections, is conducted to verify that all components meet the required specifications.

Impact on Various Industries

pipe valve fitting factory

The products manufactured in pipe valve fitting factories are indispensable in numerous industries. In the oil and gas sector, for instance, these fittings are vital for transporting crude oil and natural gas safely from extraction sites to processing plants. Similarly, in the chemical industry, they are essential for handling hazardous materials, where precise control over flow and pressure can prevent leaks and accidents.

Additionally, pipe valve fittings are crucial in the water supply and wastewater management sectors. They help maintain the integrity of water distribution systems, ensuring clean water delivery and efficient sewage treatment processes. The manufacturing of these components contributes significantly to public health and safety.

Economic Contributions

The pipe valve fitting manufacturing sector also has notable economic implications. It provides jobs and supports local economies through the creation of skilled labor positions in engineering, manufacturing, and quality control. As industries grow and expand, the demand for high-quality fittings increases, prompting investment in research and development to innovate and improve manufacturing processes.

Moreover, as environmental regulations tighten globally, the demand for energy-efficient and sustainable piping solutions has surged. Factories focusing on developing eco-friendly materials and energy-efficient production methods help promote sustainable industrial practices.

Conclusion

In conclusion, pipe valve fitting factories are vital components of modern industry, providing essential products that ensure the smooth and safe flow of fluids in critical systems. As we continue to advance technologically and address environmental challenges, the role of these factories will undoubtedly evolve, contributing to greater efficiency, safety, and sustainability in various sectors. Recognizing and supporting this industry is crucial for the continued growth and resilience of the global economy.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025