Suppliers of High Temperature Ball Valves for Industrial Applications

High Temperature Ball Valve Suppliers Ensuring Quality and Reliability

When it comes to controlling the flow of fluids in high-temperature applications, selecting the right ball valve supplier is crucial. High temperature ball valves are designed to operate efficiently under extreme thermal conditions, making them essential components in industries such as oil and gas, power generation, chemical processing, and more. The right supplier not only offers quality products but also provides the expertise and support necessary to meet the specific requirements of these demanding environments.

Understanding High Temperature Ball Valves

High-temperature ball valves are typically constructed from durable materials like stainless steel, Inconel, or other high-strength alloys that can withstand elevated temperatures and pressures. These valves feature a hollow, perforated ball that allows or blocks flow when rotated. Their design provides a tight seal, ensuring minimal leakage and increased safety in operations. Given their ability to handle extreme temperatures, which often exceed 200°C (392°F), they are integral to maintaining operational efficiency and safety.

Selecting a Supplier

When searching for high-temperature ball valve suppliers, several factors need to be considered

1. Material Quality The materials used in manufacturing the valves must be suitable for high-temperature applications. Suppliers should provide details regarding the grades of metals used, certifications, and testing methodologies.

2. Product Range A reputable supplier will offer a diverse range of ball valves, capable of accommodating various temperature and pressure ratings. This variety ensures that end-users can find valves that meet their specific operational needs.

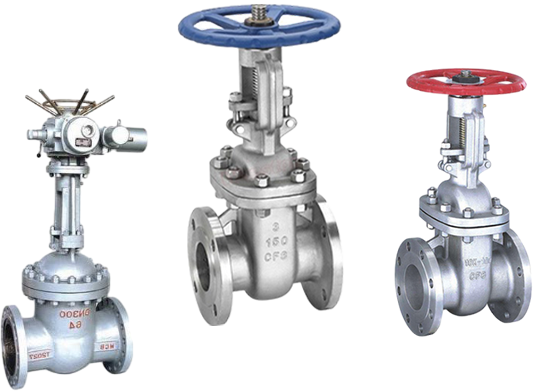

high temp ball valve suppliers

3. Custom Solutions Not all applications are the same. A good supplier will provide custom solutions tailored to unique specifications. This may include size adjustments, special coatings, or unique designs for specific industry applications.

4. Industry Experience Suppliers with a proven track record in high-temperature applications are better equipped to understand the challenges and requirements in this area. Their experience often translates into superior product recommendations and support.

5. Regulatory Compliance Ensure that the supplier adheres to international standards and certifications, such as ISO, API, or ASME. Compliance with these standards is essential for ensuring product safety and reliability.

6. After-Sales Support Good suppliers provide excellent after-sales support, including installation assistance, maintenance, and warranty services. This support can be invaluable in high-stakes environments where downtime can lead to significant losses.

Leading Suppliers in the Market

Several companies are recognized as leaders in the high-temperature ball valve market. These suppliers typically invest in research and development to enhance their product offerings continually. They also maintain robust stock levels and quick delivery options to meet the urgent demands of their clients.

In conclusion, choosing the right high-temperature ball valve supplier is essential for ensuring the reliability and efficiency of operations in challenging environments. By focusing on quality materials, product variety, industry experience, and compliance with standards, companies can find suppliers that help them navigate the complexities of high-temperature applications safely and efficiently. The right partner not only provides products but also contributes valuable expertise that strengthens operational integrity.

-

The Versatility of Ball Valves in Fluid Control SystemsNewsJun.10,2025

-

The Practical Benefits of Centerline Butterfly ValvesNewsJun.10,2025

-

The Benefits of Bellows Seal Globe Valves for Industrial SystemsNewsJun.10,2025

-

The Advantages of Offset Butterfly ValvesNewsJun.10,2025

-

Ductile Gate Valves: Strong, Reliable, and Essential for Every SystemNewsJun.10,2025

-

Cast Iron Gate Valves: A Reliable Solution for Every SystemNewsJun.10,2025

-

Why Choose a Brass Gate Valve for Superior Performance and DurabilityNewsMay.09,2025