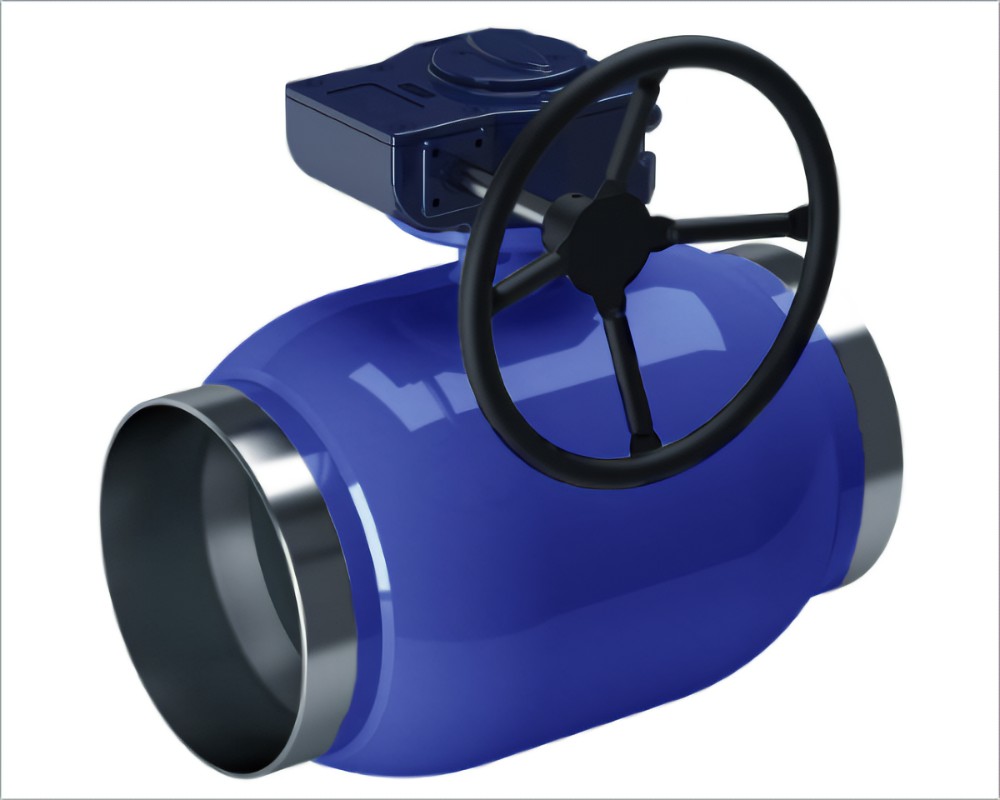

slow close check valve

Understanding Slow Close Check Valves A Comprehensive Overview

In various engineering applications, particularly in fluid dynamics and piping systems, ensuring the proper flow of fluids while preventing backflow is crucial. This is where slow close check valves come into play. These devices, often overlooked, are essential for maintaining the integrity and efficiency of hydraulic systems.

A slow close check valve operates by allowing fluid to flow in one direction while preventing it from flowing backward. Unlike traditional check valves that shut rapidly, slow close check valves are designed to close gradually. This feature minimizes hydraulic shock or water hammer, which can cause significant damage to piping systems. Water hammer occurs when a fluid in motion is forced to stop or change direction suddenly, creating pressure surges that can lead to pipe bursts, joint failures, and other system failures.

The slow closing mechanism of these valves is generally achieved through a combination of design elements, which may include a damping system or a weighted disc. As the fluid flows through the valve, the closure element (typically a disc or a ball) takes its time to return to the closed position, creating a gentler transition. This controlled closure is particularly beneficial in systems with high fluid velocities or large diameter pipes where the risk of hydraulic shock is most pronounced.

slow close check valve

Applications for slow close check valves are diverse. They are commonly used in water supply systems, irrigation, fire protection systems, and HVAC applications. By preventing reverse flow, they also help in maintaining the efficiency of pumps and protecting equipment from potential damage. Moreover, slow close check valves are critical in scenarios where backflow could lead to contamination of clean water supplies.

When selecting a slow close check valve for a particular application, several factors need to be considered. These include the type of fluid, pressure, temperature, and the specific flow characteristics of the system. Valves can be made from various materials such as brass, stainless steel, and plastic, each offering different levels of durability and resistance to corrosion.

Installation is another vital aspect to consider. Proper placement of the valve within the system can significantly affect its performance. It is essential to ensure that the valve is correctly oriented according to the flow direction and that it is installed in a location where it can operate effectively without interference from other system components.

In conclusion, slow close check valves play a pivotal role in fluid management by preventing backflow and reducing the risks associated with hydraulic shock. Their gradual closing mechanism enhances system reliability and longevity, making them an invaluable component in many engineering systems. As industries continue to expand and evolve, the importance of incorporating such essential devices into their fluid management solutions cannot be overstated. Understanding their functionality and application ensures better design and implementation of efficient and safe hydraulic systems.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025