មករា . 14, 2025 11:11

Back to list

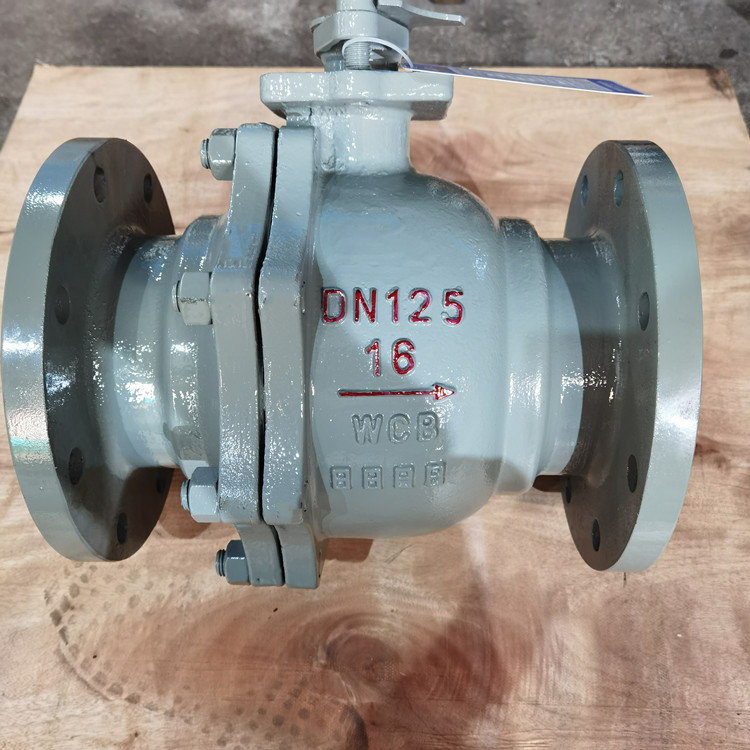

X43W/T-10 Cast Iron Flanged Plug Valve

Gas needle valves are critical components in precision control of gas flow in various industrial applications. Their design allows for fine-tuning the flow rate, essential in processes where accuracy is paramount. These valves are indispensable in gas chromatography systems, laboratory applications, and many other industries where they provide precise control over gas flows.

Trustworthiness in the manufacturing and supply of gas needle valves stems from rigorous quality control processes and adherence to industry standards. Established manufacturers conduct extensive testing to ensure their valves meet or exceed operational requirements. This dedication to quality is crucial in building trust, as it assures users that the valves will perform reliably under specified conditions. Moreover, traceability in production - knowing the origin of materials and the manufacturing process - further consolidates trust in the product's quality and reliability. In terms of hands-on experience, users often report that ease of operation and maintenance are significant factors in their preference for certain valve brands. A reliable gas needle valve should offer smooth operation, without the need for excessive force, and should exhibit minimal wear over time. Maintenance tasks, such as seal replacement and cleaning, are simplified when valves are designed with accessibility in mind. Practical insights also highlight the importance of installation instructions provided by the manufacturer; clear guidelines can prevent errors that might compromise valve performance. Bringing these elements together, the gas needle valve serves as a testament to the seamless integration of engineering precision, material science, and industry expertise. Its application in critical systems underscores the importance of selecting a valve that not only meets the technical specifications but also comes from a reputable source. So, when selecting a gas needle valve, consider the intricacies of your application and choose a product backed by solid expertise and a proven track record of reliability – ensuring safety and efficacy in all its uses.

Trustworthiness in the manufacturing and supply of gas needle valves stems from rigorous quality control processes and adherence to industry standards. Established manufacturers conduct extensive testing to ensure their valves meet or exceed operational requirements. This dedication to quality is crucial in building trust, as it assures users that the valves will perform reliably under specified conditions. Moreover, traceability in production - knowing the origin of materials and the manufacturing process - further consolidates trust in the product's quality and reliability. In terms of hands-on experience, users often report that ease of operation and maintenance are significant factors in their preference for certain valve brands. A reliable gas needle valve should offer smooth operation, without the need for excessive force, and should exhibit minimal wear over time. Maintenance tasks, such as seal replacement and cleaning, are simplified when valves are designed with accessibility in mind. Practical insights also highlight the importance of installation instructions provided by the manufacturer; clear guidelines can prevent errors that might compromise valve performance. Bringing these elements together, the gas needle valve serves as a testament to the seamless integration of engineering precision, material science, and industry expertise. Its application in critical systems underscores the importance of selecting a valve that not only meets the technical specifications but also comes from a reputable source. So, when selecting a gas needle valve, consider the intricacies of your application and choose a product backed by solid expertise and a proven track record of reliability – ensuring safety and efficacy in all its uses.

Latest news

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025