Motorized Actuator for Butterfly Valve Applications and Benefits in Fluid Control Systems

Understanding Motorized Actuators for Butterfly Valves

In the realm of fluid control systems, the butterfly valve stands out due to its compact design and efficient operation. When modified with a motorized actuator, these valves become even more versatile and effective in various industrial applications. This article explores the significance of motorized actuators for butterfly valves, their operational principles, advantages, and applications.

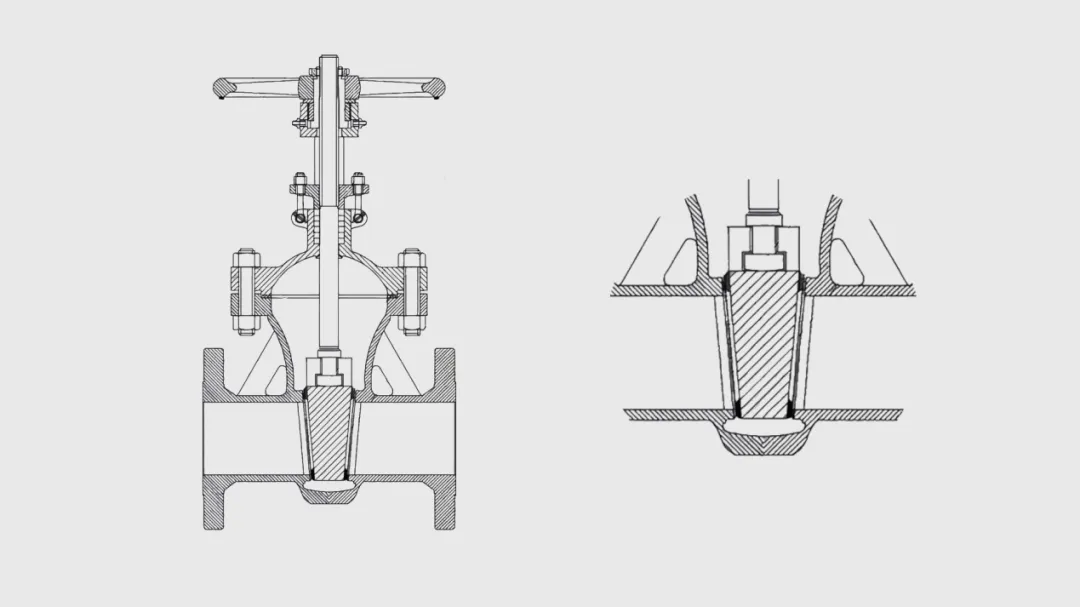

What is a Butterfly Valve?

A butterfly valve is a quarter-turn valve that uses a rotating disc to regulate the flow of fluids. The disc, mounted on a shaft, rotates around an axis in the center of the valve body. When the disc is parallel to the flow direction, the valve is fully open; when perpendicular, it is fully closed. This simple mechanism makes butterfly valves suitable for applications requiring quick shut-off and flow regulation.

Motorized Actuators An Overview

An actuator is a device that converts energy into mechanical motion. In the context of butterfly valves, motorized actuators use electrical energy to automatically open or close the valve without the need for manual intervention. This automation is crucial for enhancing efficiency, particularly in processes where flow needs to be adjusted frequently and quickly.

Motorized actuators can come in various forms, including electric, pneumatic, and hydraulic types. Electric actuators are the most common for valve automation, providing precise control and easy integration with modern control systems such as SCADA.

How Motorized Actuators Work

Motorized actuators for butterfly valves typically consist of a motor, gearbox, and a positioner. The motor drives the gearbox, which reduces the motor's speed and increases the torque. The positioner ensures that the valve reaches the desired position, providing feedback to the control system for accurate control.

When a control signal is sent to the actuator, the motor rotates the valve disc to the specified angle. Common control signals include 4-20 mA or Modbus, which are standard in many industrial automation systems. The actuator can also be programmed for various operational modes, such as fail-safe, where the valve remains in a predetermined position during a power failure.

Advantages of Motorized Actuators for Butterfly Valves

1. Automated Operation The primary advantage of motorized actuators is that they eliminate the need for manual operation, which saves time and reduces human error.

butterfly valve motorized actuator

3. Integration with Control Systems These actuators can be easily integrated into existing control systems, allowing for remote operation and monitoring, which is essential for modern industrial applications.

4. Reduced Maintenance Motorized actuators often require less maintenance than manual valves, as they have fewer moving parts exposed to wear and tear.

5. Enhanced Safety In hazardous environments, remote operation of butterfly valves via motorized actuators increases safety by minimizing human exposure to dangerous conditions.

Applications of Motorized Butterfly Valves

Motorized butterfly valves with actuators are utilized in various industries, including

- Water Treatment They are used to regulate flow in water treatment plants, ensuring that the right amount of water is processed at any time.

- Chemical Processing In chemical plants, these valves control the flow of various chemicals, minimizing the risk of spills and accidents.

- HVAC Systems In heating, ventilation, and air conditioning systems, motorized butterfly valves help regulate air flow and improve energy efficiency.

- Food and Beverage These valves ensure precise control of liquid flow in food processing, contributing to both product safety and quality.

Conclusion

Motorized actuators for butterfly valves represent a significant advancement in flow control technology. By providing automated, precise, and efficient operation, these systems enhance productivity across various industries. As automation continues to evolve, we can expect to see even greater integration and innovation in motorized actuator technology, further improving the effectiveness and reliability of butterfly valves in fluid management systems. Embracing these advancements means positioning businesses for success in an increasingly dynamic industrial landscape.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025