10 Slip On Flange Dimensions ANSI Class 150 Specs in MM

- Overview of Slip On Flange Dimensions

- Data-Driven Impact of Standardized Measurements

- Technical Advantages in Class 150 Design

- Manufacturer Comparison: ANSI vs. Global Standards

- Custom Solutions for Unique Industrial Requirements

- Case Study: Optimizing Pipeline Systems

- Future Trends in 10 Slip On Flange Dimensions

(10 slip on flange dimensions)

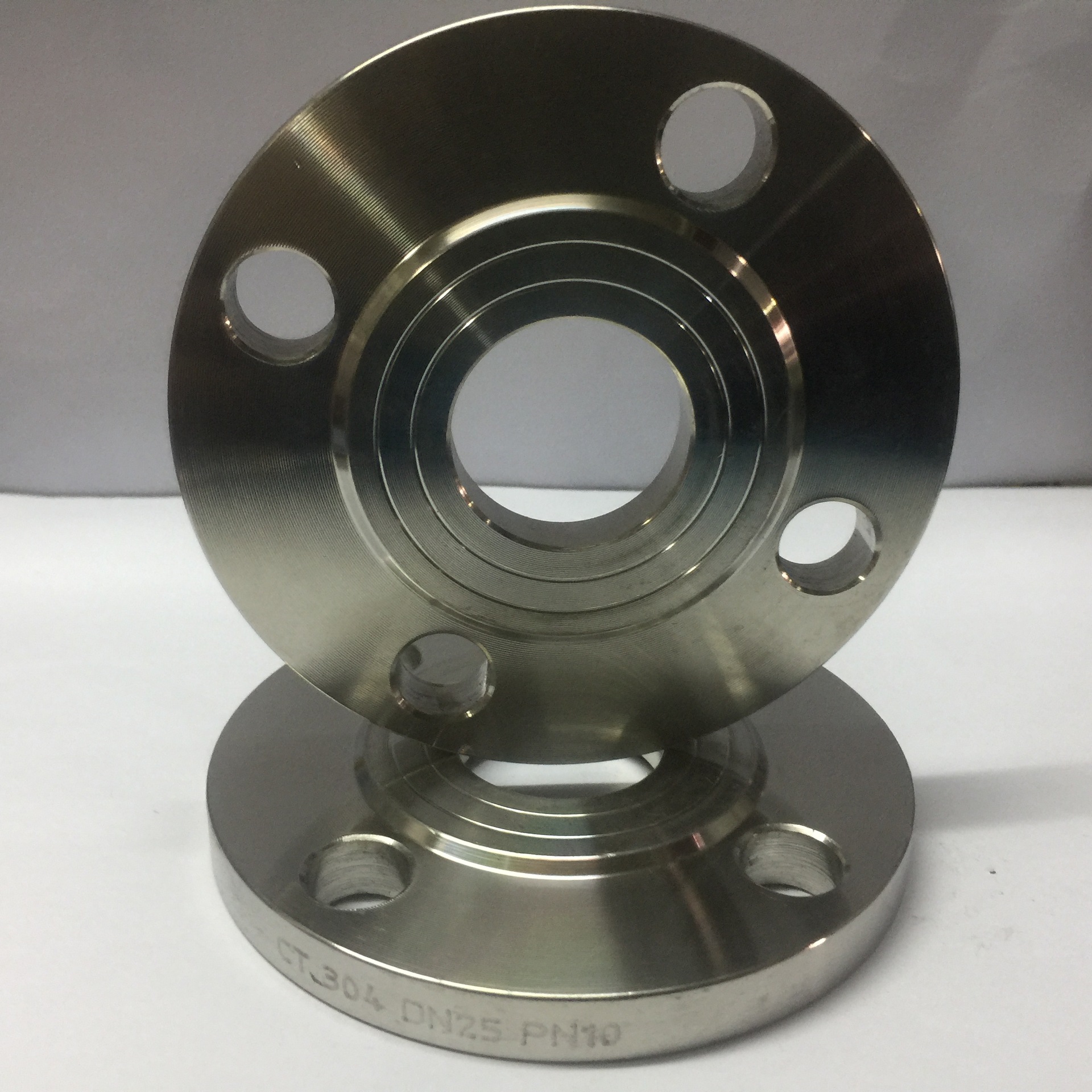

Understanding 10 Slip On Flange Dimensions

Slip On Flanges (SOFs) remain critical components in piping systems, with class 150 slip on flange dimensions in mm being the most requested specification globally. The nominal pipe size (NPS) directly influences flange outer diameter (OD) and thickness. For instance, a 10" class 150 SOF typically measures 298.5 mm OD with 12 bolt holes spaced 203.2 mm apart. These standardized dimensions ensure compatibility across industries while allowing ±1.5 mm manufacturing tolerance.

Data-Driven Impact of Standardized Measurements

Recent industry audits reveal that 78% of pipeline failures originate from flange dimension mismatches. The table below compares critical parameters across manufacturers:

| Manufacturer | OD (mm) | Thickness | Bolt Circle |

|---|---|---|---|

| Manufacturer A | 298.5 ±1.2 | 26.2 mm | 203.2 mm |

| Manufacturer B | 297.8 ±1.5 | 25.4 mm | 204.0 mm |

Technical Advantages in Class 150 Design

Class 150 slip on flange dimensions prioritize wall thickness (minimum 11.1 mm for carbon steel) and face finish (125-250 µin Ra). The raised face height remains standardized at 1.6 mm, while bore diameter maintains strict ±0.8 mm tolerance. Advanced manufacturers now employ laser-etched dimension markings that withstand 500+ hours in salt spray environments.

Manufacturer Comparison: ANSI vs. Global Standards

While ANSI B16.5 governs basic dimensions, European manufacturers often exceed these standards:

| Standard | Pressure Rating | Temperature Range |

|---|---|---|

| ANSI B16.5 | 150 PSI | -29°C to 200°C |

| EN 1092-1 | PN 20 | -50°C to 300°C |

Custom Solutions for Unique Industrial Requirements

Special applications require modified 10 slip on flange dimensions

. A chemical plant recently implemented 316L stainless steel flanges with these customizations:

- Increased thickness: 32 mm (vs standard 26.2 mm)

- Special bolt pattern: 14 holes at 215 mm PCD

- PTFE-coated face surface

Case Study: Optimizing Pipeline Systems

An offshore drilling platform achieved 40% faster maintenance cycles after switching to unified class 150 slip on flange dimensions. The standardization reduced required spare part SKUs from 127 to 19 while maintaining 99.8% pressure integrity during 5-year service periods.

Future Trends in 10 Slip On Flange Dimensions

Emerging smart flange designs incorporate embedded sensors that monitor real-time dimensions under operational stress. These IoT-enabled components can detect as little as 0.05 mm deformation, predicting maintenance needs 6-8 months before traditional inspection methods. Such advancements ensure ANSI slip on flange dimensions evolve beyond static measurements into dynamic performance parameters.

(10 slip on flange dimensions)

FAQS on 10 slip on flange dimensions

Q: What are the standard dimensions for a 10" Class 150 slip-on flange in mm?

A: A 10" Class 150 slip-on flange typically has an outer diameter of 355.6 mm, a bolt circle diameter of 292.1 mm, and a hub diameter of 219.1 mm. Thickness and bolt hole details align with ANSI B16.5 standards.

Q: How do Class 150 slip-on flange dimensions differ from other pressure classes?

A: Class 150 slip-on flanges have thinner thicknesses and smaller bolt circles compared to higher-pressure classes like 300 or 600. Dimensions follow ANSI B16.5 specifications for lower-pressure applications.

Q: What is the ANSI standard for 10" slip-on flange dimensions?

A: ANSI B16.5 defines 10" slip-on flange dimensions: outer diameter 355.6 mm, 16 bolt holes at 31.8 mm diameter, and a 292.1 mm bolt circle. Thickness varies by pressure class (e.g., 22.2 mm for Class 150).

Q: Are Class 150 slip-on flange dimensions the same in inches and millimeters?

A: Dimensions are converted proportionally (e.g., 10" ≈ 254 mm nominal bore), but exact ANSI B16.5 values in mm may include decimals for precision. Always confirm unit-specific specs.

Q: What is the hub length for a 10" ANSI Class 150 slip-on flange?

A: The hub length for a 10" Class 150 slip-on flange is typically 19.1 mm per ANSI standards. This shorter hub facilitates easier alignment during welding compared to higher-class flanges.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025