Innovative Solutions for Check Valve Gasket Efficiency and Durability

The Importance of Gaskets in Check Valves

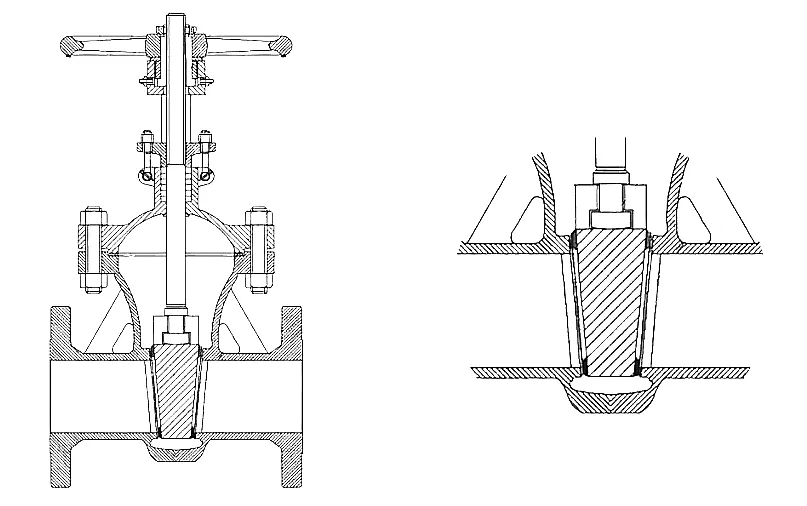

Check valves are crucial components in numerous fluid systems, ensuring that fluid flows in one direction and preventing backflow. Among the many parts that make a check valve operational, the gasket plays a vital role in sealing and maintaining the integrity of the system. In this article, we will explore the significance of gaskets in check valves, the types of materials used, and the considerations for maintenance and replacement.

Understanding Gaskets in Check Valves

A gasket is a mechanical seal that fills the space between two or more mating surfaces in a valve assembly. In the case of check valves, the gasket serves to prevent leakage and ensure that the valve operates efficiently. It is typically positioned between the valve body and the cover, creating a tight seal that holds under pressure.

The function of the gasket is particularly important when dealing with fluids that are under high pressure or that may react with the materials of the valve. A well-fitted gasket prevents fluid from escaping, which not only saves on resources but also minimizes environmental contamination.

Materials Used for Gaskets

The selection of gasket material is crucial

. Different applications require different materials based on temperature, pressure, and the type of fluid being handled. Some common materials used for check valve gaskets include1. Rubber Commonly used for lower pressure applications, rubber offers excellent resilience and can handle moderate temperatures. Its flexibility allows it to conform to imperfections in sealing surfaces.

2. PTFE (Teflon) Known for its chemical resistance, PTFE is ideal for applications where corrosive fluids are present. It can handle a wide range of temperatures and is less prone to wear compared to rubber.

check valve gasket

3. Metallic Gaskets These are used in high-pressure applications and provide exceptional durability. They can withstand extremely high temperatures and are often used in industrial settings.

4. Cork Gaskets While not as common, cork can be used in lower pressure environments. It is often employed when a more environmentally friendly option is desired.

Maintenance and Replacement Considerations

Regular maintenance of check valves is critical to ensure their reliability. Gaskets are subject to wear and tear due to factors such as temperature fluctuations, pressure, and exposure to chemicals. Over time, gaskets can degrade, leading to leaks and potential failure of the valve.

Signs that a gasket may need replacement include

- Visible wear or deformation - Leakage around the valve - A noticeable drop in system pressure

When replacing a gasket, it is essential to select the appropriate material for the specific application. Contractors must ensure that the gasket fits properly and that the sealing surfaces are clean and smooth before installation. This will help prevent future leaks and extend the lifespan of the check valve.

Conclusion

In conclusion, gaskets are an integral part of check valves, playing a significant role in system efficiency and safety. Proper material selection, regular maintenance, and timely replacement are essential to prevent failures and ensure smooth operation. As industries continue to evolve and demand more advanced fluid control systems, the importance of high-quality gaskets will only continue to grow, making them a crucial component in various engineering applications. Understanding the characteristics and maintenance needs of gaskets in check valves is vital for operators and engineers alike, as it significantly impacts the overall performance of fluid systems.

-

Breakthrough in Domestic Low Temperature Valve Technology in ChinaNewsAug.18,2025

-

From Machinery to Intelligent Brain: The Digital Transformation Wave of the Valve IndustryNewsAug.18,2025

-

PCVEXPO 2025NewsAug.18,2025

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025