Butterfly Valve Offset - Understanding Design and Applications

Understanding Butterfly Valve Offset Its Importance and Applications

Butterfly valves are critical components in various industrial processes, used primarily to regulate or isolate fluid flow. They operate through a rotating disc that allows for quick opening and closing, making them ideal for applications requiring fast shut-off. One essential aspect of butterfly valve design is the concept of offset. Understanding butterfly valve offset can significantly influence performance and efficiency in fluid handling systems.

What is Butterfly Valve Offset?

Butterfly valve offset refers to the positioning of the valve's disc relative to the centerline of the pipeline. There are two primary types of offsets concentric and eccentric. In concentric designs, the disc is centered with the pipeline, while in eccentric designs, the disc is offset from the center. Eccentric butterfly valves are further categorized into single eccentric (or high-performance) and double eccentric (or triple eccentric) valves.

Advantages of Eccentric Butterfly Valves

1. Reduced Torque Requirements Eccentric butterfly valves require less torque to operate compared to their concentric counterparts. This translates to lower energy consumption and reduced wear on components.

2. Improved Sealing Capability The design of eccentric butterfly valves often enhances the sealing performance, making them suitable for applications where zero leakage is crucial. The disc’s offset minimizes contact with the seat during opening and closing, reducing the chances of wear and damage over time.

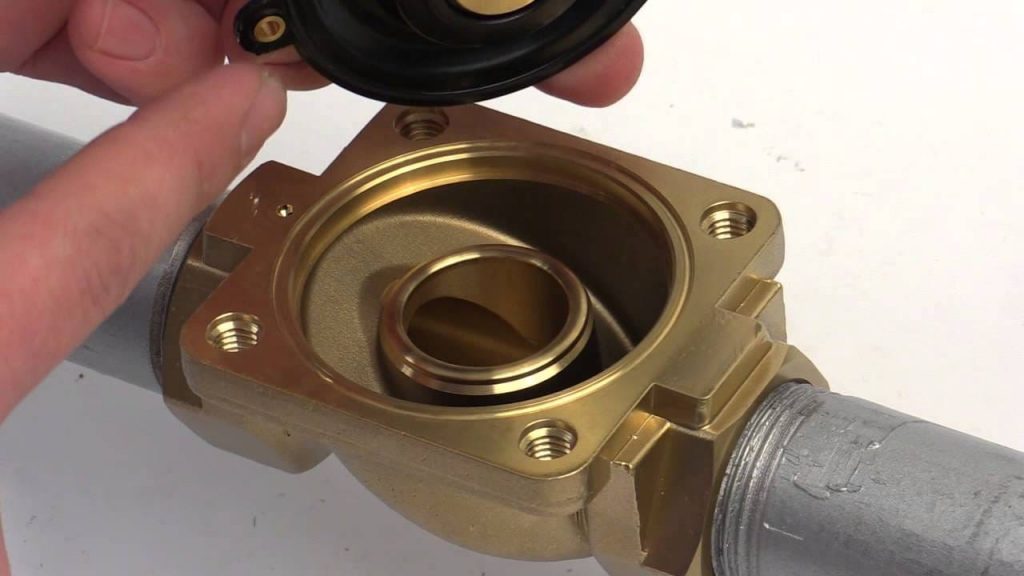

butterfly valve offset

3. Higher Flow Efficiency Eccentric valves have streamlined flow paths that facilitate better fluid dynamics. This results in less turbulence and reduced pressure drops, enhancing overall system efficiency.

4. Versatility in Applications The unique design allows eccentric butterfly valves to handle a wide range of media, including corrosive or abrasive fluids. They are used in various industries, including water treatment, chemical processing, oil and gas, and HVAC systems.

Applications of Butterfly Valve Offset

Butterfly valves with offset designs are widely utilized in numerous applications. In the water treatment industry, they play a vital role in regulating flow rates and maintaining system pressure. In chemical processing, they are critical for safely isolating sections of pipelines during maintenance or emergencies. Moreover, in HVAC systems, these valves help control air flow efficiently, contributing to energy savings and improved heating/cooling performance.

Conclusion

In summary, butterfly valve offset is a crucial factor that influences the performance and suitability of these valves in different applications. The choice between concentric and eccentric designs can significantly affect operational efficiency, sealing capabilities, and maintenance requirements. As industries continue to seek ways to improve efficiency and reliability, understanding the principles behind butterfly valve offsets will remain vital in the selection and implementation of these essential components in fluid handling systems.

By making informed choices regarding butterfly valve design, engineers and operators can enhance system performance and drive significant cost savings in their operations.

-

The Key to Fluid Control: Exploring the Advantages of Ball Valves in Industrial SystemsNewsJul.09,2025

-

The Versatile World of 1, 2, and 3 Piece Ball ValvesNewsJul.09,2025

-

Stainless Steel Ball Valves: The Ideal Choice for Efficient Flow ControlNewsJul.09,2025

-

Optimizing Fluid Control with Ball Float ValvesNewsJul.09,2025

-

Manual Gate Valves: Essential for Control and EfficiencyNewsJul.09,2025

-

Everything You Need to Know About Butterfly ValvesNewsJul.09,2025

-

The Versatility of Wafer Type Butterfly ValvesNewsJul.08,2025